Electrochemical test apparatus and electrochemical test method for corrosion on reclaimed water pipeline system in flowing system

A technology for testing devices and piping systems, used in measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc. problems, to achieve the effect of making the production method standard and feasible, improving the accuracy and standardization, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

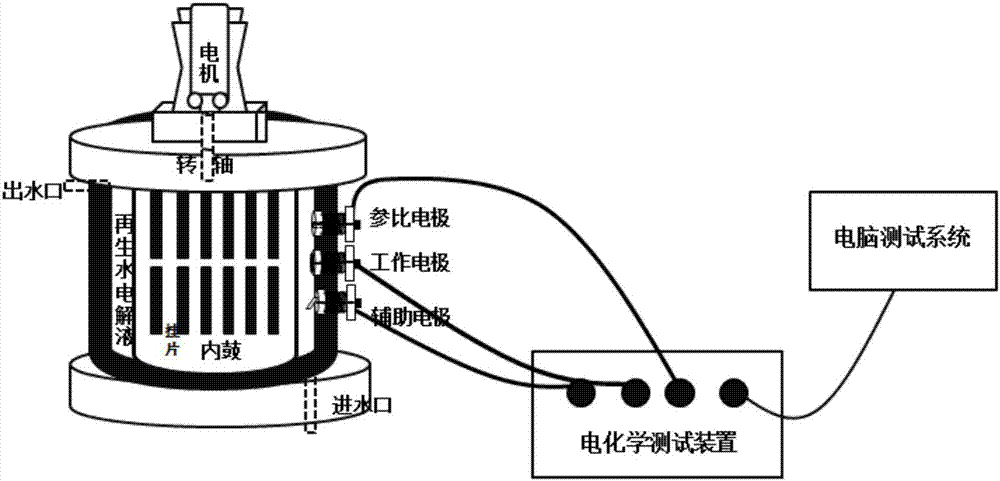

[0040] In "Urban Sewage Recycling-Urban Miscellaneous Water Quality", the amount of residual chlorine in the clean water pool entering the pipe network after 30 minutes of contact is regulated as ≥1.0mg / L, and the amount of residual chlorine at the end of the pipe network is required to be ≥0.2mg / L , due to the high concentration of AOC and suspended solids in reclaimed water, resulting in a large amount of chlorine consumption, especially in long-distance pipeline transportation, it is difficult to ensure the residual chlorine at the end of the pipeline network, resulting in a large number of microbial reproduction. Therefore, this subject carried out three concentrations of NaClO and ClO in the influent respectively 1mg / L, 2mg / L and 4mg / L. 2 Disinfectants were tested for 30 days each, and the diversity of microorganisms in the corrosion scale was measured by means of microbial high-throughput sequencing, and the corrosion mechanism of the reclaimed water pipeline in the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com