Implementation method of meatball boiling with multidirectional discharging

A method for realizing meatballs, which is applied to cooking utensils, the structure of cooking utensils, plug-ins, etc., can solve the problems of uneven heating of liquid, dirt on the outer wall of the pot, and long cooking time, so as to avoid partially cooked Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

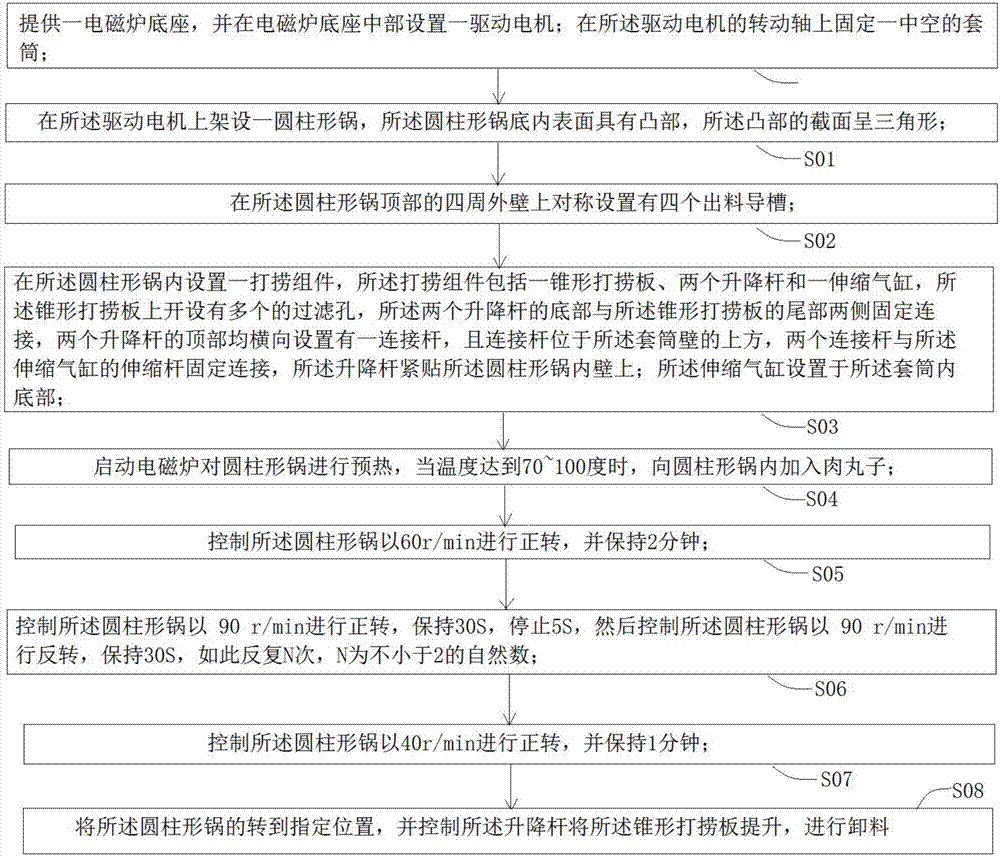

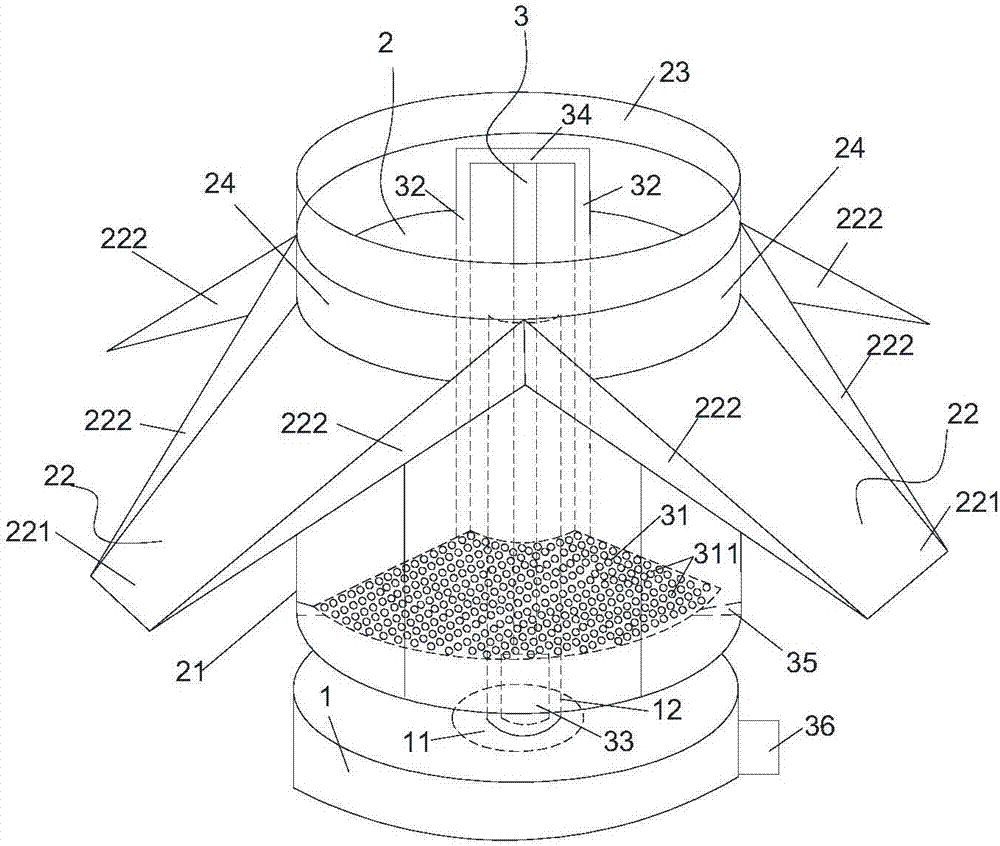

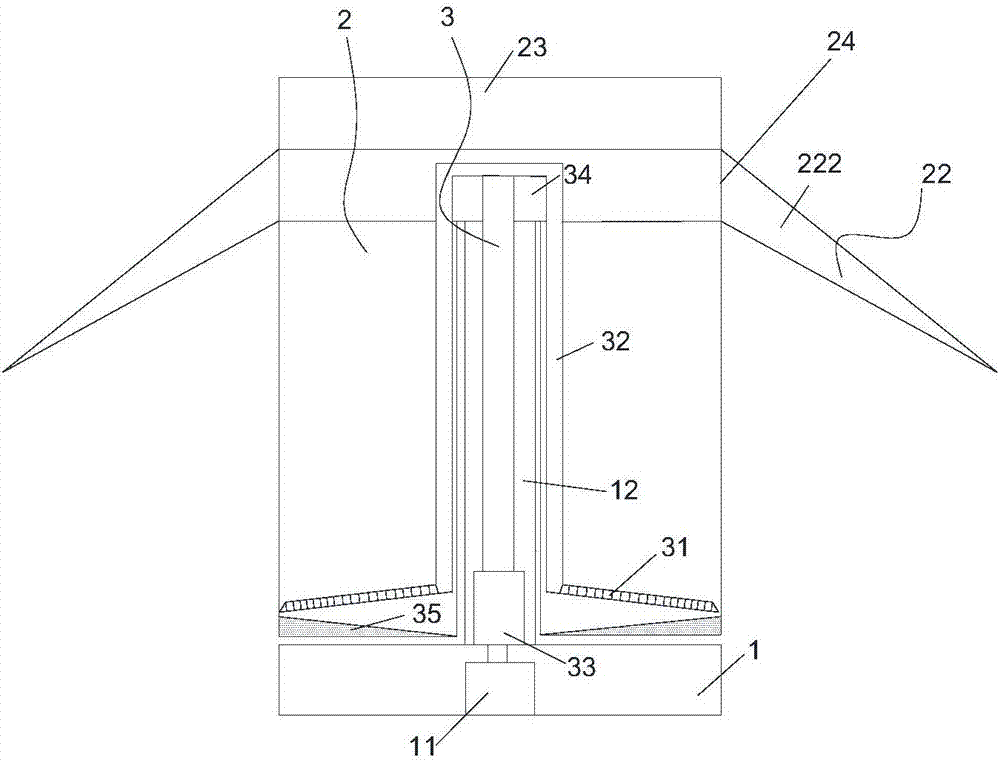

[0021] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a method for realizing meatball cooking with multi-directional discharge, including the following steps:

[0022] Step S01: providing an induction cooker base 1, and setting a drive motor 11 in the middle of the induction cooker base; fixing a hollow sleeve 12 on the rotation shaft of the drive motor;

[0023] Step S02: erecting a cylindrical pot 21 on the driving motor, the inner surface of the bottom of the cylindrical pot has a convex portion 35, and the cross section of the convex portion is triangular;

[0024] Step S03: Four discharge guide grooves 22 are symmetrically arranged on the outer wall around the top of the cylindrical pot;

[0025] Step S04: Install a salvage assembly 3 in the cylindrical pot, the salvage assembly includes a conical salvage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com