Micro-fluidic chip for realizing liquid droplet upward and downward separation, original droplet upward floating and injected substance sinking

A microfluidic chip and droplet technology, applied in fluid controllers, laboratory appliances, laboratory containers, etc., can solve problems such as activity, efficacy, performance, state changes, affecting applications, and adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

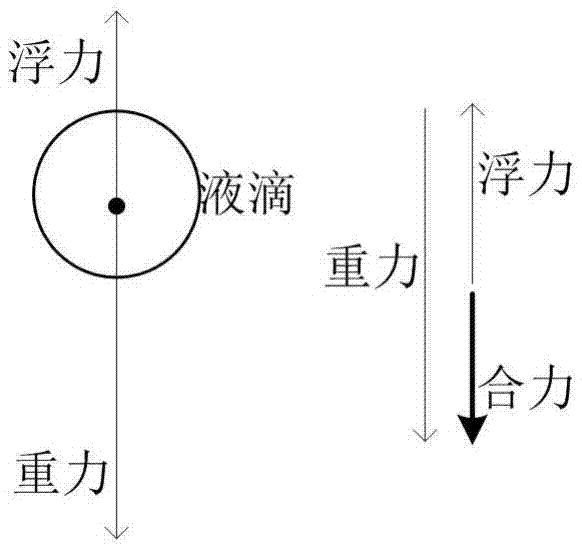

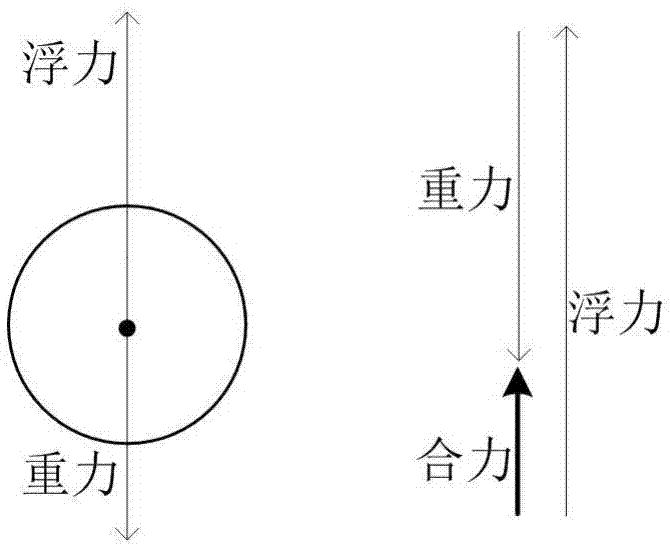

[0087] "Up and down sorting, injecting and sinking" droplet sorting: light droplets become heavier after being injected into the material, and the droplets are sorted along the upper and lower branches.

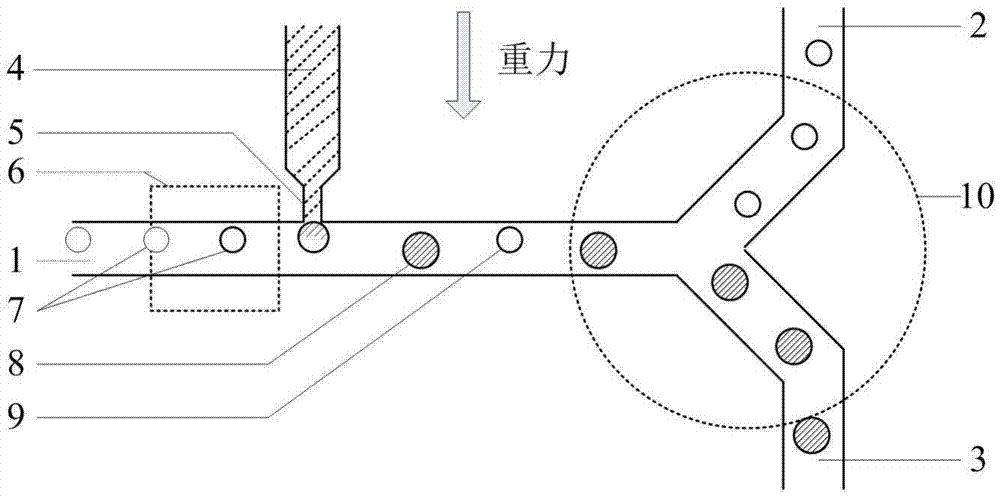

[0088] figure 1 It is a schematic diagram of this embodiment, and the number 1 is the liquid inlet interface; the number 2 is one liquid outlet interface; the number 3 is another liquid outlet interface; the number 4 is the substance injected into the droplet; the number 5 is the liquid filling port; The number 6 is the detection area; the number 7 is the liquid that has just entered the channel through the liquid inlet port; the number 8 is the liquid drop that has been added through the liquid filling port; A channel fork structure that implements sorting.

[0089] In this embodiment, the density of the liquid droplets of the present invention is lower than that of the surrounding liquid, and the density is higher than that of the surrounding liquid after selective injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com