A method and device for degassing metal powder

A metal powder and powder technology, which is applied in the field of metal powder degassing method and its device, can solve the problem of limited conduction of gas molecules, achieve the effect of low cost, simple equipment, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

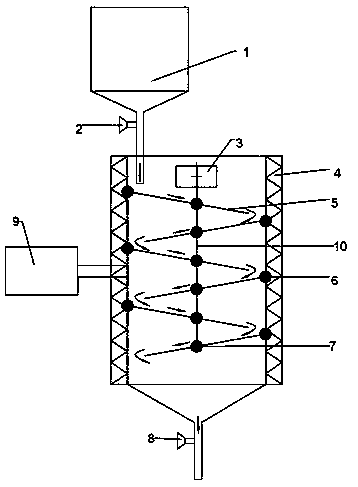

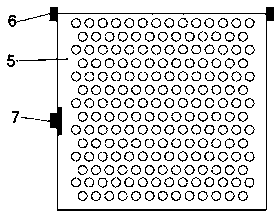

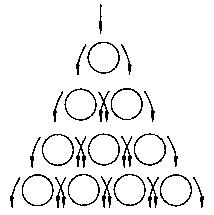

[0028] 1) Place the powder storage tank 1 on the box of the degassing equipment and connect it to the vacuum valve 2; 2) Close the powder inlet vacuum valve 2, open the powder outlet vacuum valve 8, turn on the vacuum pump 9 and the heating element 4, The casing connected to the powder discharge vacuum valve 8 is degassed at a temperature of 580℃; 3) When the vacuum degree of the cabinet is less than 0.01Pa, adjust the angle between the powder spreading plate and the horizontal plane to 15° through the control rod, and turn on the vibrator 3. , The vibration frequency is 100Hz; 4) Open the powder inlet vacuum valve 2 to start powder feeding, and the powder feeding rate <80kg / h; 5) During the powdering process, if the vacuum degree is greater than 0.01Pa, reduce the powdering rate; 6) If the powder has segregation, reduce the inclination angle of the powder spreader and increase the vibration frequency to make the powder flat shop.

Embodiment 2

[0030] 1) Place the titanium alloy powder storage tank 1 on the box of the degassing equipment and connect it to the vacuum valve 2; 2) Close the powder inlet vacuum valve 2, open the powder outlet vacuum valve 8, turn on the vacuum pump 9 and the heating element 4, right The envelope connected to the closed box and the powder discharge vacuum valve 8 is degassed at a temperature of 550°C; 3) When the vacuum of the box is less than 0.01Pa, adjust the angle between the powder spreading board and the horizontal plane to 12° through the control lever, and start the vibration The vibration frequency is 80Hz; 4) Open the powder inlet vacuum valve 2, and start powder feeding, the powder feeding rate is 30kg / h; 5) During the powder feeding process, if the vacuum degree is greater than 0.01 Pa, reduce the powder feeding rate; 6) If The powder has segregation phenomenon, which can reduce the inclination of the powder spreading board and increase the vibration frequency to make the powder...

Embodiment 3

[0032] 1) Place the superalloy powder storage tank 1 on the box of the degassing equipment and connect it to the vacuum valve 2; 2) Close the powder inlet vacuum valve 2, open the powder outlet vacuum valve 8, open the vacuum pump 9 and the heating element 4, right The envelope connected to the closed box and the powder discharge vacuum valve 8 is degassed, and the temperature is 400℃; 3) When the vacuum of the box is less than 0.01Pa, adjust the angle between the powder spreading board and the horizontal plane to 8° through the control lever, and start the vibration The vibration frequency is 50Hz; 4) Open the powder inlet vacuum valve 2, and start powder feeding at a powder feeding rate of 60kg / h; 5) During the powder feeding process, if the vacuum is greater than 0.01 Pa, reduce the powder feeding rate; 6) If The powder has segregation phenomenon, which can reduce the inclination of the powder spreading board and increase the vibration frequency to make the powder spread even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap