A screen window system based on electrostatic dust collection and automatic dust removal

A technology of automatic dust removal and electrostatic dust collection, applied in the direction of electrostatic effect separation, external electrostatic separator, windows/doors, etc., can solve problems such as irreversible, easy to be blown out by the wind, magnetic reduction and other problems, to achieve a good life experience and Enjoy the effect of convenient and quick cleaning of dust and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

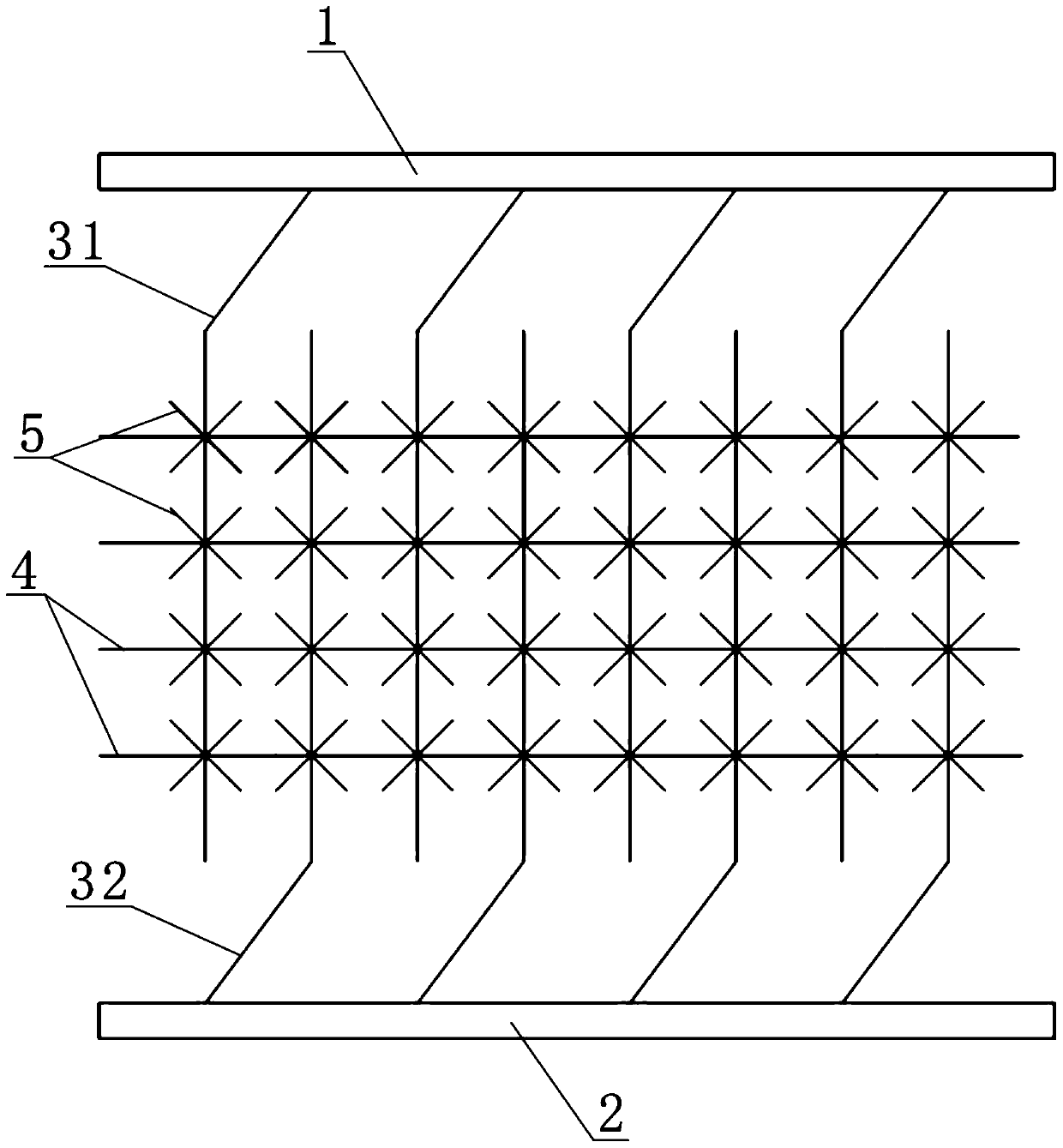

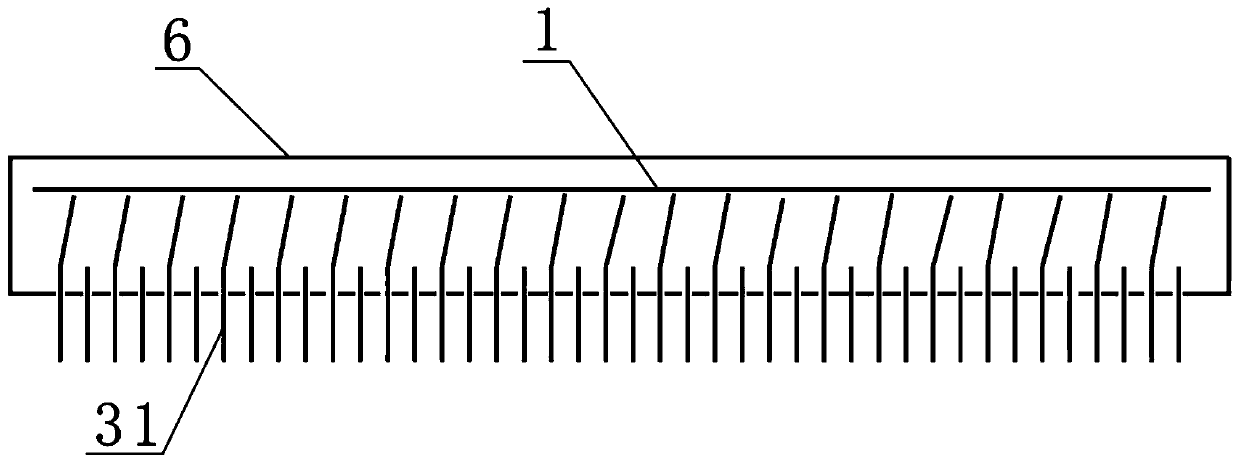

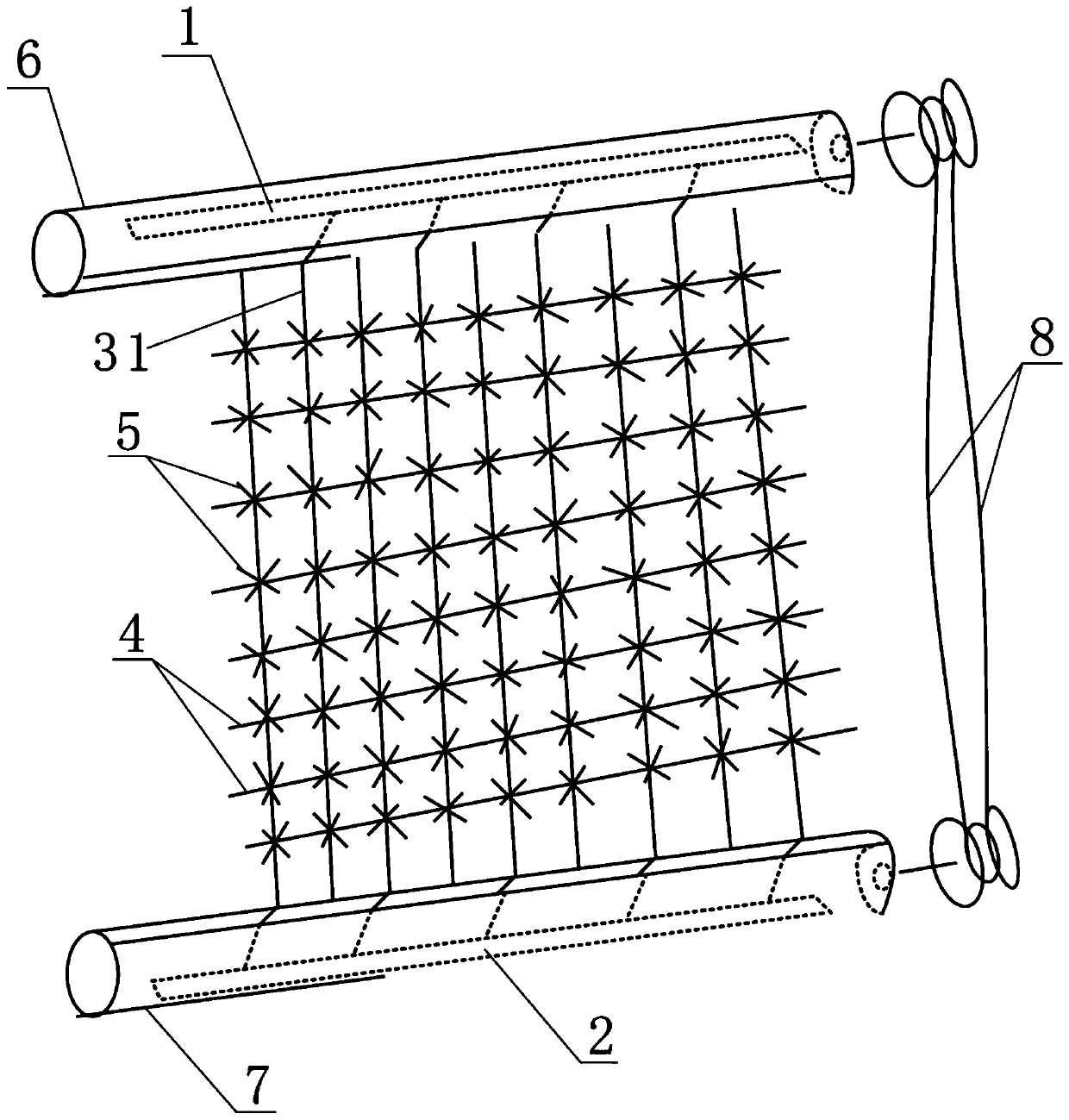

[0022] Such as Figure 1 to Figure 5 As shown, a screen window system based on electrostatic dust collection and automatic dust removal, including the positive grid plate 1 of the power supply, the negative grid plate 2 of the power supply, the hollow insulating runner shaft 6 at the top of the screen window, the hollow insulating runner shaft 7 at the bottom of the screen window, and the rainproof outside of the top runner Cover 10 and the outer rain cover of the bottom runner, the positive grid plate 1 of the power supply and the negative grid plate 2 of the power supply are arranged parallel to each other, the positive grid plate 1 of the power supply is electrically connected with several positive conductive aluminum wires 31, and the negative grid plate 2 of the power supply is electrically connected with A plurality of negative conductive aluminum wires 32, all positive conductive aluminum wires 31 and all negative conductive aluminum wires 32 are arranged parallel to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com