Device for vibration monitoring data of turboshaft engine

A turboshaft engine and vibration monitoring technology, which is applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve problems such as wear, engine damage, corrosion, etc., and achieve high performance, convenient monitoring and management, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

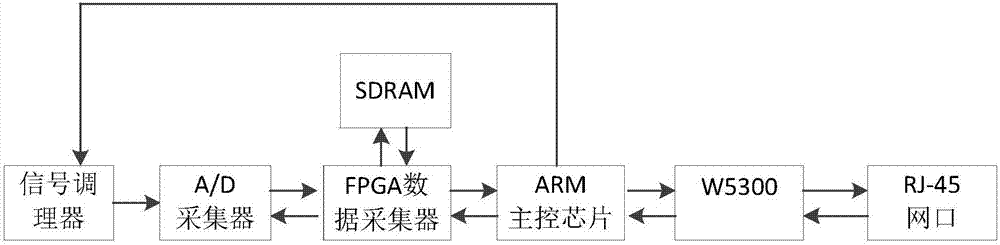

[0014] Such as figure 1 As shown, a device for vibration monitoring data of a turboshaft engine includes a main control chip ARM, a high-speed Ethernet chip W5300 connected to the main control chip ARM for two-way communication and used for network transmission, and a high-speed Ethernet chip W5300 for two-way communication The connected RJ-45 network port, the two-way communication connection with the main control chip ARM and the data acquisition chip FPGA used for communication, the synchronous dynamic random access memory SDRAM connected with the data acquisition chip FPGA two-way communication, and the two-way communication connection with the data acquisition chip FPGA An A / D collector, and a signal conditioner connected to the A / D collector, wherein the main control chip ARM is connected to the signal conditioner.

[0015] Further, the main control chip ARM adopts STM32 series.

[0016] Specifically, the FPGA chip adopts EP2C5 series.

[0017] Under the control of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com