Outer surface defect detection method and device for cylindrical workpiece

A defect detection, cylindrical technology, applied in the direction of optical testing flaws/defects, etc., can solve the problem of inaccurate detection results of photographing effects, and achieve the effect of avoiding accidental and accurate defect analysis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

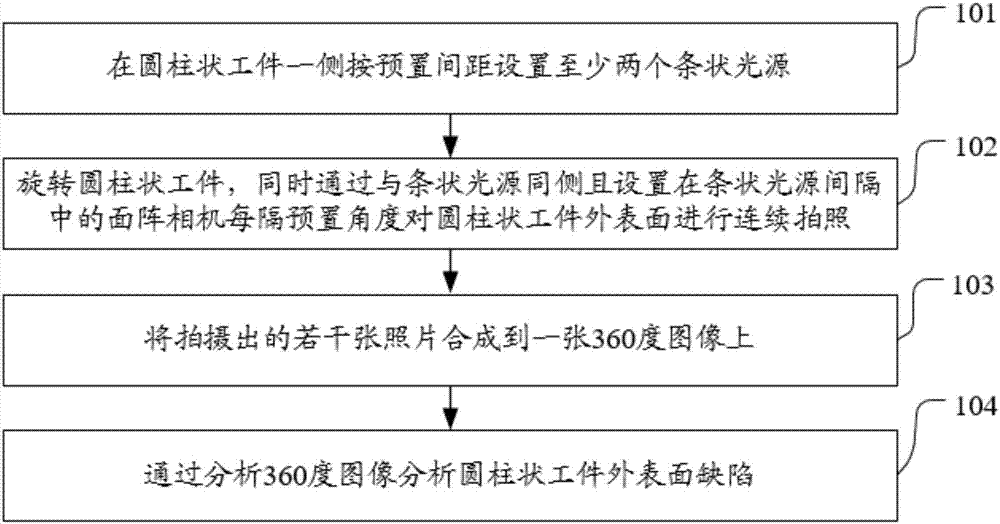

[0045] see figure 1 , the embodiment of the present invention provides a first embodiment of a method for detecting defects on the outer surface of a cylindrical workpiece, including:

[0046] 101. Set at least two strip light sources at a preset distance on one side of the cylindrical workpiece;

[0047] In the embodiment of the present invention, firstly, at least two strip light sources need to be set on one side of the cylindrical workpiece according to a preset distance. Just set an appropriate number of strip light sources.

[0048] 102. Rotate the cylindrical workpiece, and at the same time take continuous pictures of the outer surface of the cylindrical workpiece at preset angles through an area array camera on the same side as the strip light source and arranged in the interval of the strip light source;

[0049] In the embodiment of the present invention, after setting at least two bar-shaped light sources at a preset distance on one side of the cylindrical workpie...

no. 2 example

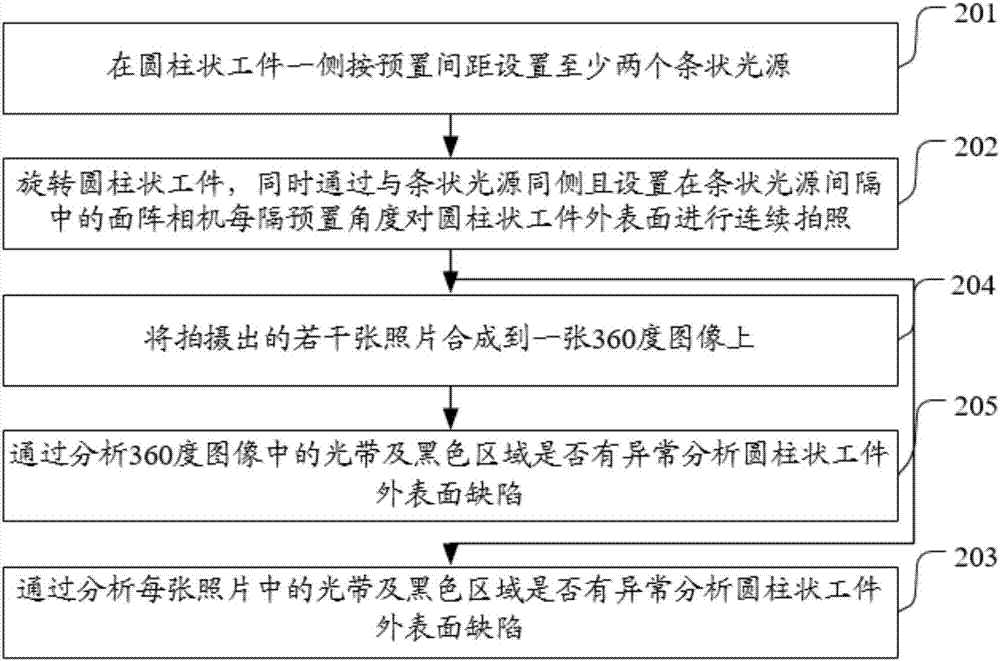

[0054] see figure 2, the embodiment of the present invention provides a second embodiment of a method for detecting defects on the outer surface of a cylindrical workpiece, including:

[0055] 201, setting at least two strip light sources at a preset distance on one side of the cylindrical workpiece;

[0056] In the embodiment of the present invention, firstly, at least two strip light sources need to be arranged on one side of the cylindrical workpiece at a preset distance.

[0057] 202. Rotate the cylindrical workpiece, and at the same time take continuous pictures of the outer surface of the cylindrical workpiece at preset angles through an area array camera on the same side as the strip light source and arranged in the interval of the strip light source;

[0058] In the embodiment of the present invention, after setting at least two bar-shaped light sources at a preset distance on one side of the cylindrical workpiece, it is necessary to rotate the cylindrical workpiece,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com