Cyclone separator

A technology of cyclone separator and separation structure, which is applied to cyclone devices, devices whose axial directions of cyclone can be reversed, etc. problems, to achieve the effect of improved effect, high purity, and short airflow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention, and the technical solution of the present invention will be further described with reference to the accompanying drawings.

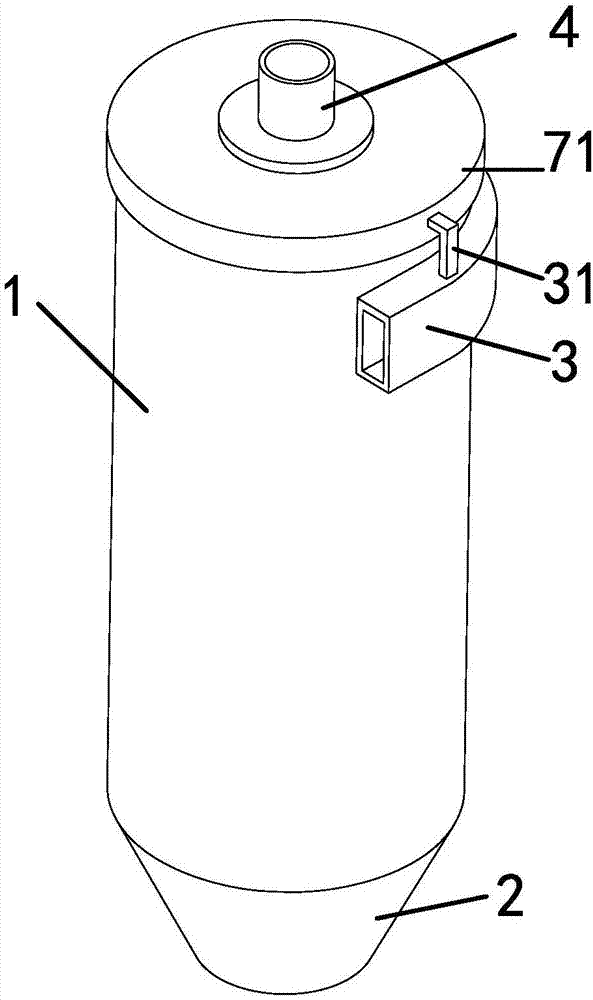

[0020] Such as figure 1 As shown, the cyclone separator includes a cylindrical body 1 and a cone 2 arranged below the cylindrical body 1. An inlet pipe 3 is provided on the upper end side of the cylindrical body 1, and an outlet pipe is provided on the top of the cylindrical body 1. In the air duct 4, the inner wall of the cylinder 1 is provided with an accelerating separation structure for accelerating the separation of solid particles.

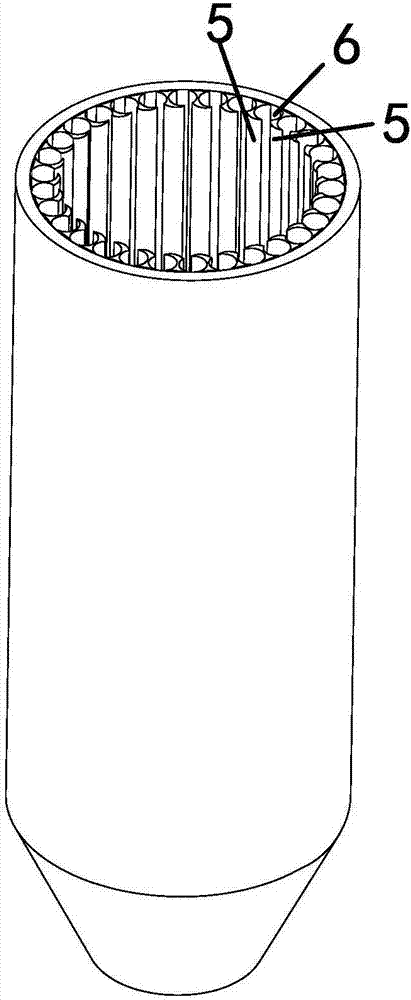

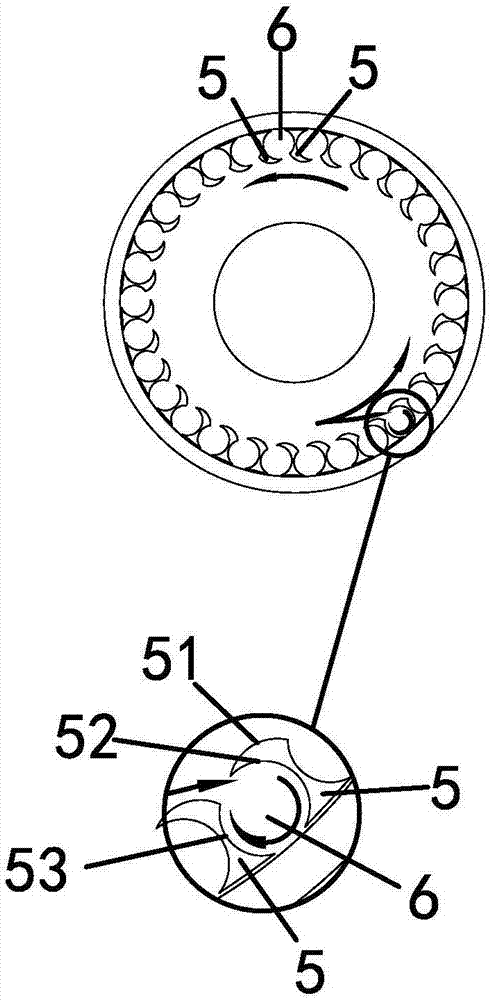

[0021] Specific acceleration separation structure such as figure 2 As shown, the accelerating separation structure includes bar-shaped stop bars 5 arranged along the axis of the cylindrical body 1. There are multiple stop bars 5 and are evenly distributed along the circumferential direction of the cylinder body 1. The gap forms a downward channel 6 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com