A safety disconnect valve

A disconnect valve and safety technology, which is applied in safety valves, balance valves, valve devices, etc., can solve the problems of disconnection or rupture of pipeline interfaces, unstable pull-off performance, complex structure, etc., and achieve stable pull-off performance, Realize the sealing and protection function requirements, and the effect of solid card reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

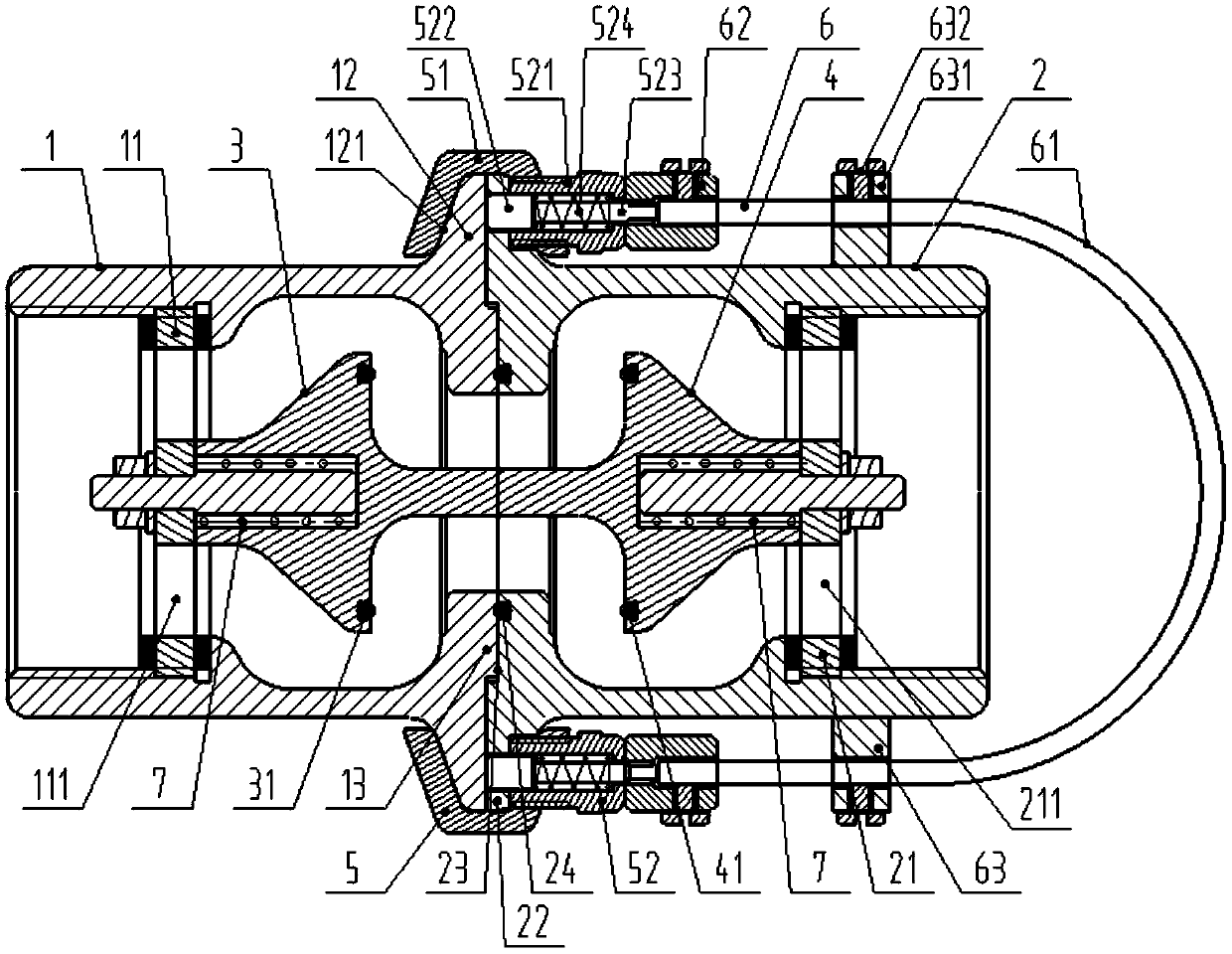

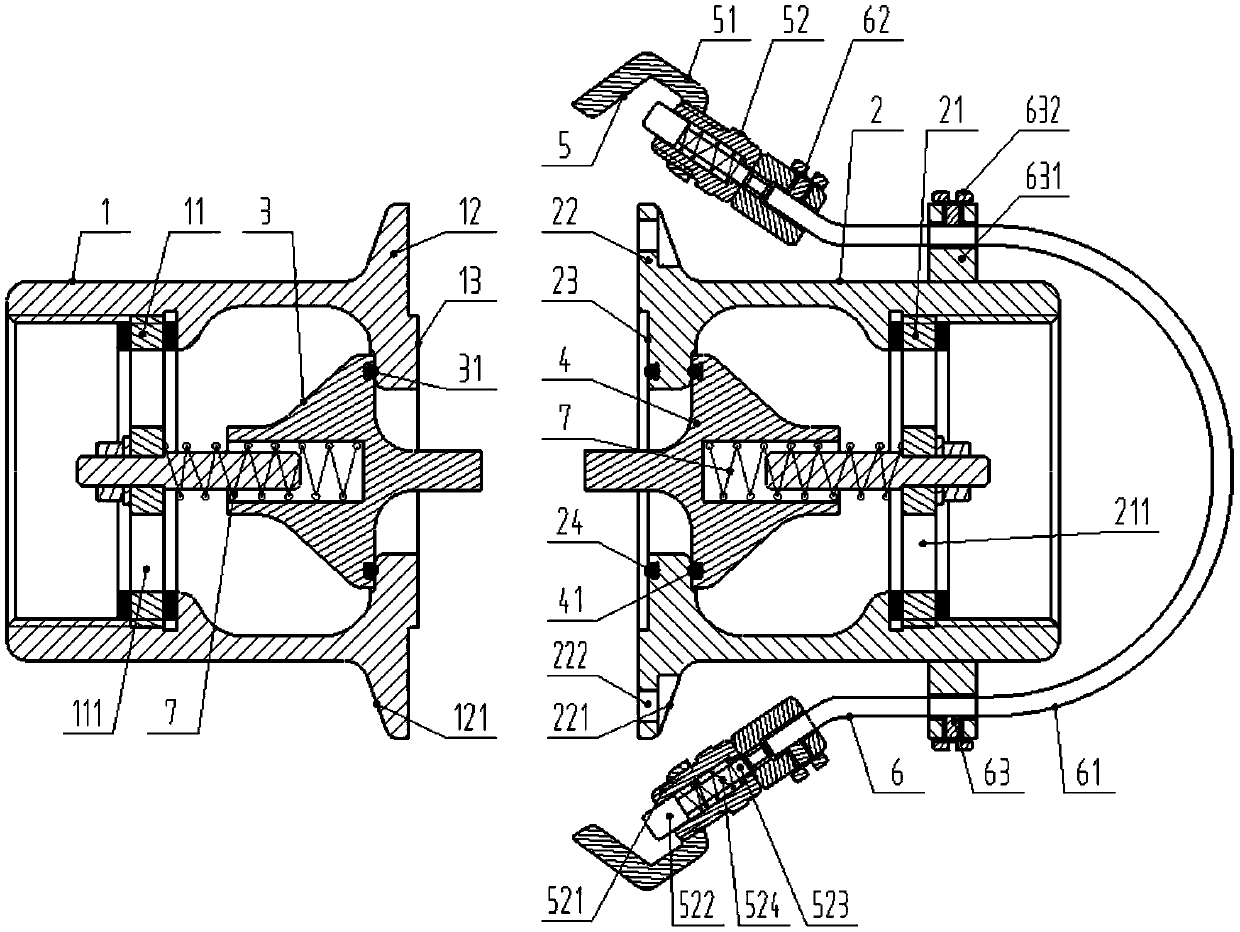

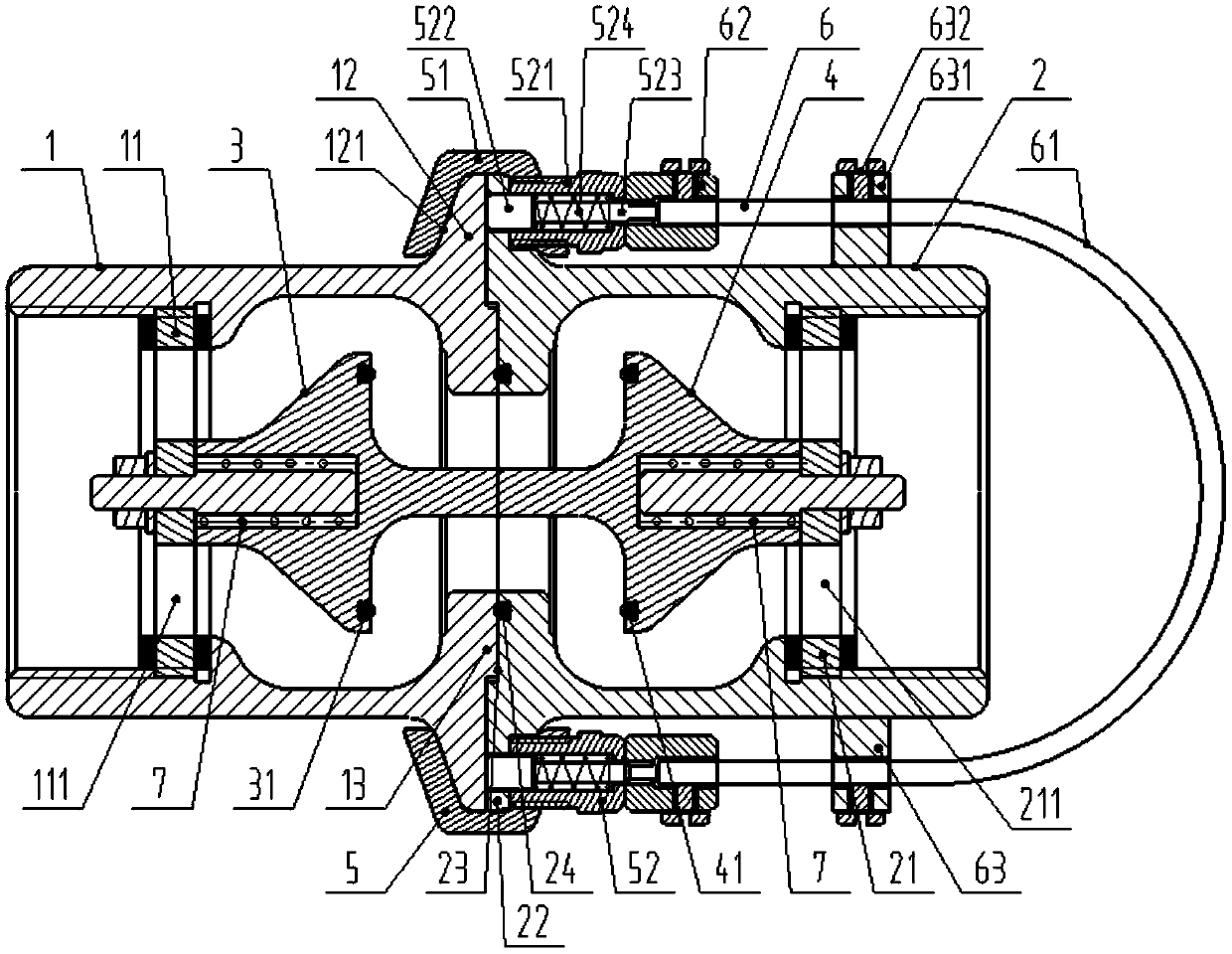

[0020] Such as Figure 1-2 As shown, a safety disconnect valve includes a left valve body 1, a right valve body 2, a left valve core 3, a right valve core 4, a middle sleeve 5 and a pull rope combination 6, and the circumferential outer wall of the left valve body 1 near the right end A left protrusion 12 is provided on the top, and the left side wall of the left protrusion is provided with a first slope 121, and the right valve body 2 is provided with a right protrusion 22 symmetrical to the left protrusion on the circumferential outer wall of the left end, and the right valve body 2 is provided with a right protrusion 22 symmetrical to the left protrusion. The right side wall of the protrusion is provided with a second inclined plane 221, and two through holes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com