Integrated tool for air tightness detection and pipe orifice retaining ring installation of automobile pipeline

A technology of air tightness detection and retaining ring, which is applied in liquid tightness measurement using liquid/vacuum degree, metal processing, tool manufacturing, etc. It can solve the problems of high labor cost, low efficiency, and unfavorable long-term development of enterprises, and achieve Easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

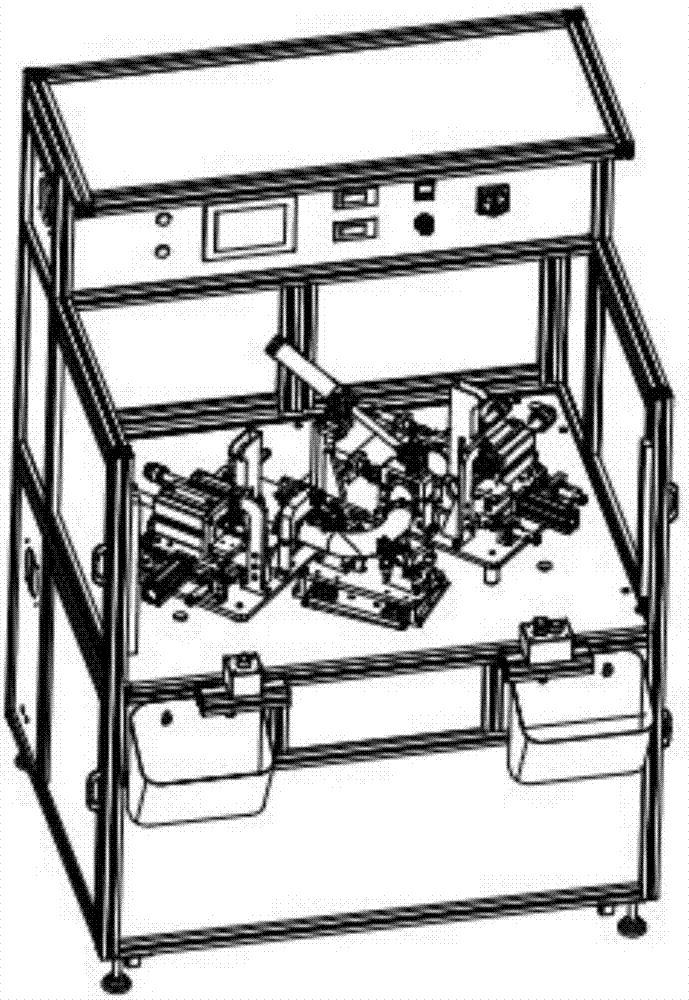

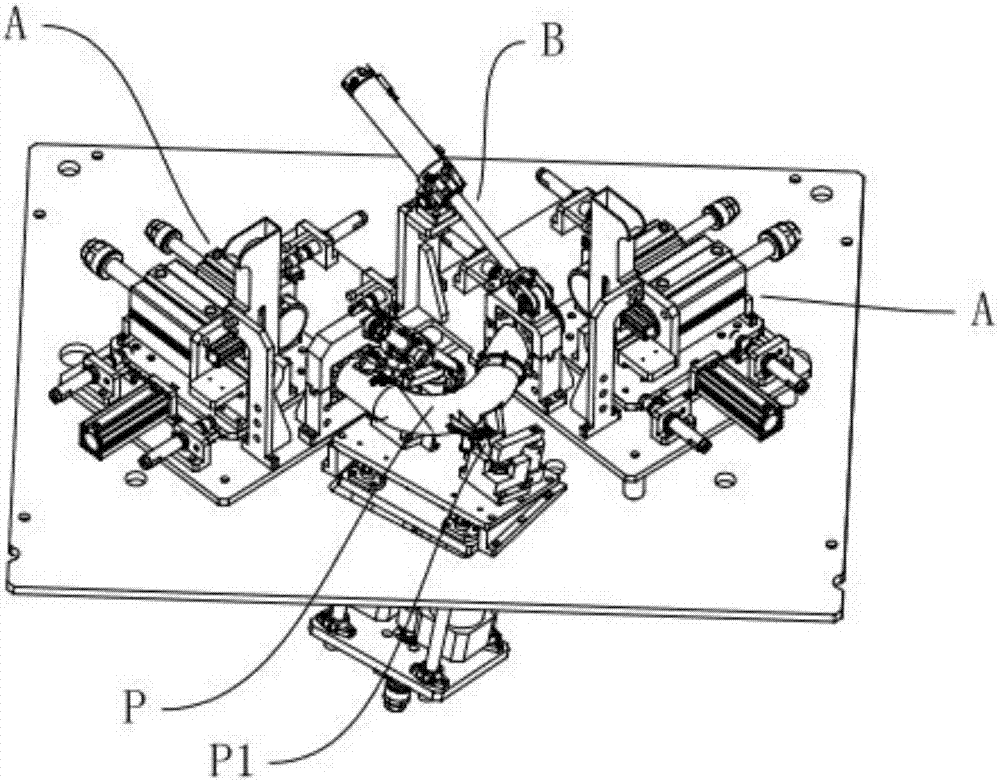

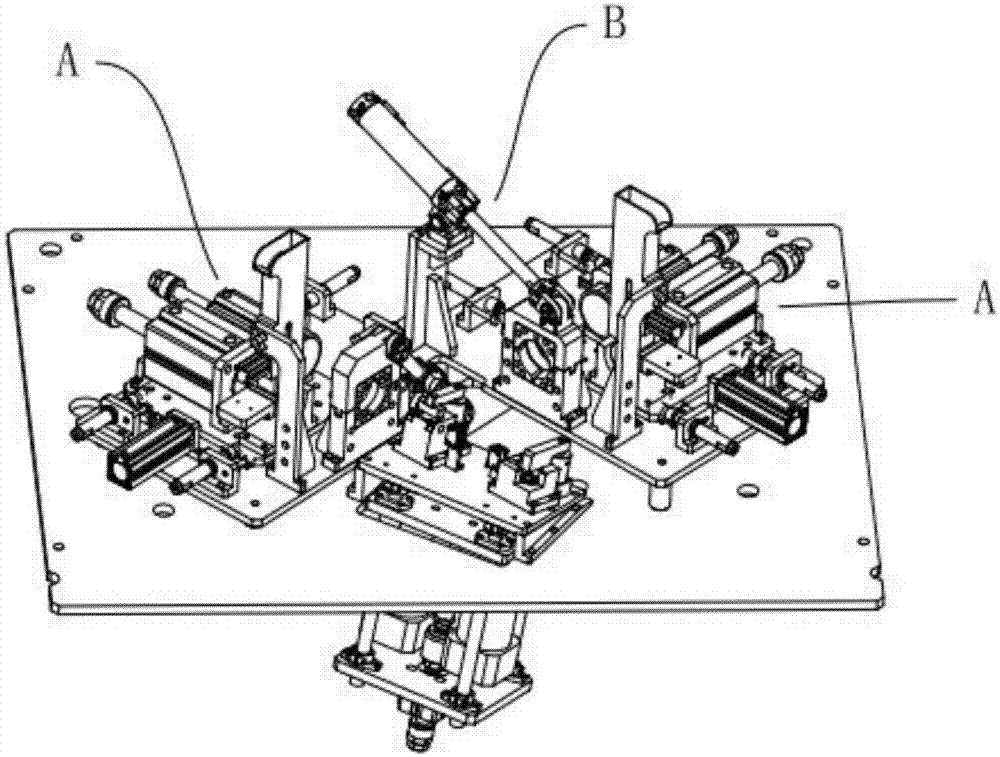

[0034] The integrated tooling for the air tightness test of the automobile pipeline and the installation of the nozzle retaining ring, please refer to the attached Figure 1-3 , the bottom plate 1, the fixing mechanism B and the air tightness detection and retaining ring installation integrated mechanism A are arranged on the workbench of the tooling, and the pipeline P is a hose. The outer wall of the pipe P is equipped with a fin P1, so that the fixing mechanism of the tooling is directly positioned and fixed with the fin P1, and then the air tightness detection and the retaining ring installation integrated mechanism at the nozzles on both sides are installed to carry out the retaining ring 11 on the nozzle Embedding and air tightness testing.

[0035] The structure of the fixing mechanism is shown in the appendix Figure 9-11 , and combined with the attached figure 2 and 3 , including a clamping mechanism for clamping the pipe body near the mouth of both sides of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com