Vehicle without blind area corresponding to a pillars and b pillar

A technology of b-pillars and blind spots, applied to the connection between vehicle components, superstructure subassemblies, superstructures, etc., can solve problems such as blind spots, and achieve the effect of improving safety and reducing the probability of traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

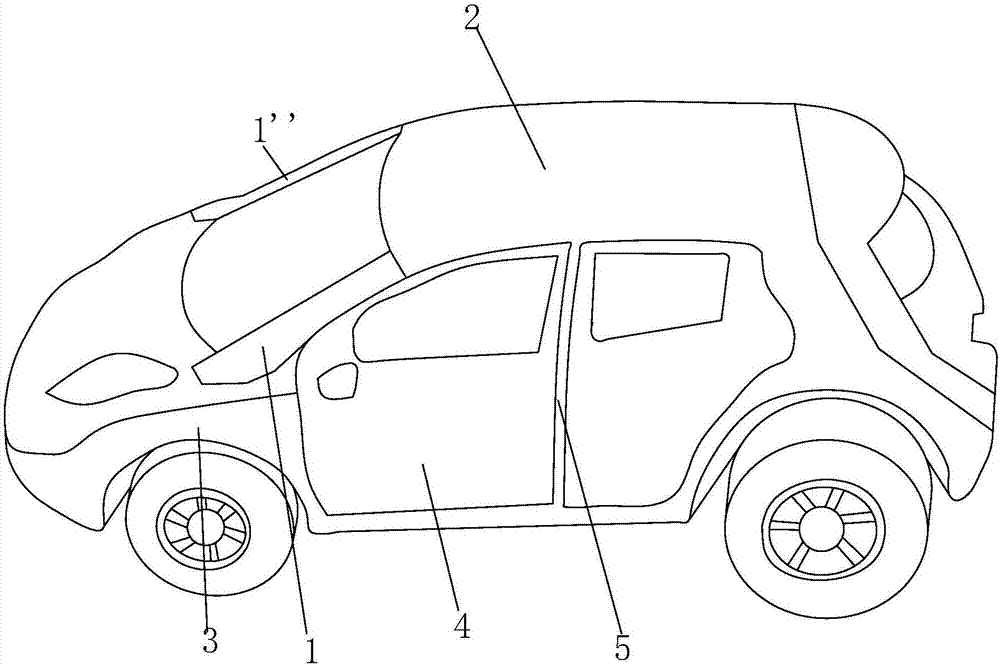

[0029] Such as figure 1 as well as figure 2 As shown, the present embodiment proposes a car without corresponding blind spots of a and b pillars, including: two a pillars 1, b pillars 1", roof 2, vehicle body 3, two front doors 4 and two connecting ribs 5, The top cover 2 is arranged above the vehicle body 3, and the two sides of the middle part of the top cover 2 are respectively connected with the vehicle body 3 through two connecting ribs 5, and the two top corners of the front end of the top cover 2 are respectively fixed with the vehicle body 3 through the a-pillar 1 and the b-pillar 1". The front door 4 is arranged between the a-pillar 1 and the adjacent middle connecting rib 5, and the other door 4 is arranged between the b-pillar 1" and the adjacent middle connecting rib. The door 4 is snap-connected with the a-pillar 1 or the b-pillar 1", and both the a-pillar 1 and the b-pillar 1" have visual functions, so as to avoid blind spots when driving due to the existence o...

Embodiment 2

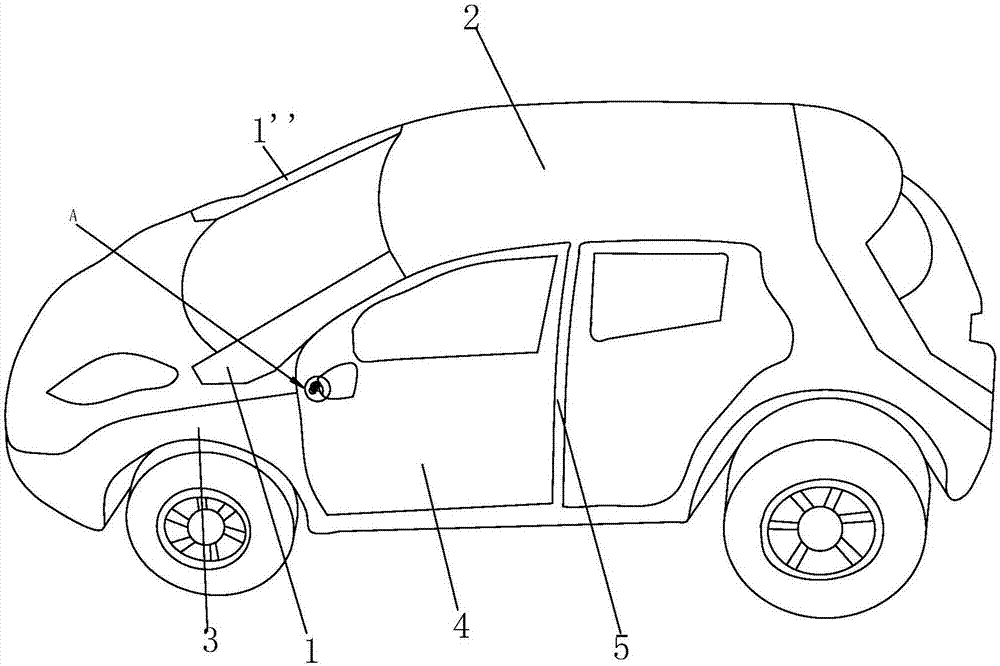

[0032] The difference between this embodiment and embodiment 1 is: in order to avoid that the a-pillar 1 and b-pillar 1" of transparent material in embodiment 1 will cause the a-pillar 1 and b-pillar 1" to be unstable or see through the a-pillar 1 and b-pillar The blind area of 1" is not clear enough. In this embodiment, a camera assembly is added to avoid the occurrence of the above phenomenon.

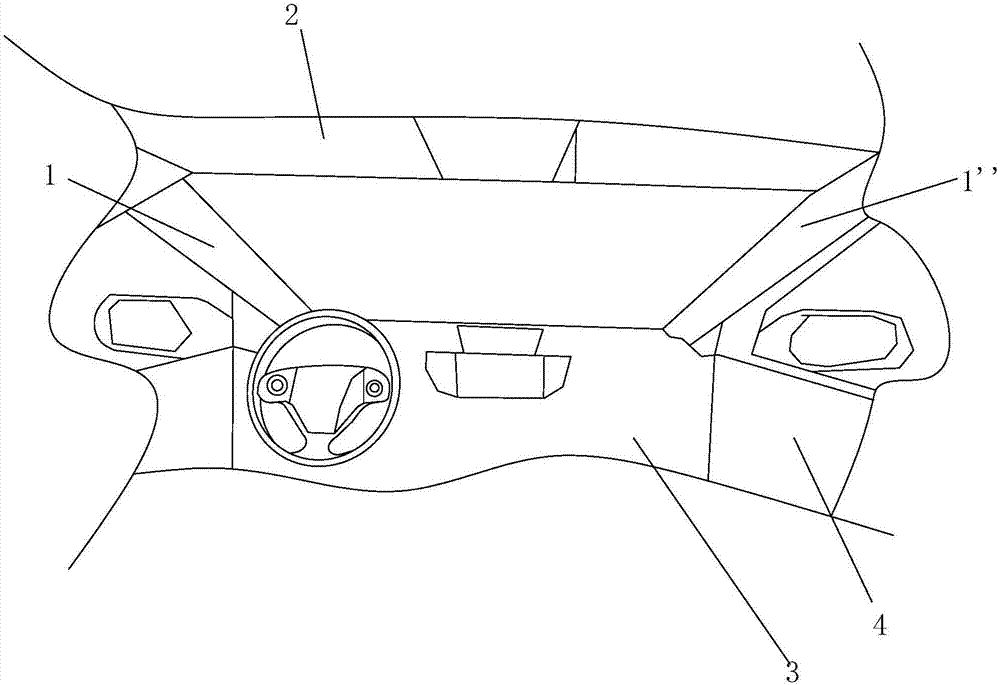

[0033] Such as image 3 as well as Figure 4 As shown, a camera assembly is provided corresponding to the a column 1 and the b column 1", each camera assembly includes a column body 11, a display screen 12, a camera 13 and a camera host (not shown in the figure), and the camera 13 is arranged on the rear view On the mirror, the camera corresponding to a-pillar 1 is used in the blind area corresponding to a-pillar 1, the camera corresponding to b-pillar 1" is used in the blind area corresponding to b-pillar 1", the camera 13 is connected to the camera host, and the output end of th...

Embodiment 3

[0040] The only difference between this embodiment and Embodiment 2 is that because the power cord assembly in Embodiment 2 is two copper wires, even if the copper wires are wrapped, the car will be exposed to the outside for a long time, so the copper wires are easily damaged. In order to design the service life Long power cord assembly, in this embodiment, the structure of the power cord assembly is designed to ensure that the first wire and the second wire are assembled in the connecting seat 133, the rotating ring 61, the rotating rod 132, the fixing seat 134 and the installation In the shell 51, the phenomenon of poor contact between the first wire and the second wire caused by the relative rotation between the rotating ring 61 and the connecting seat 133 is avoided.

[0041] Such as Figure 7 to Figure 10 As shown, the power cord assembly includes: two first wires 71, one end of the two first wires 71 is arranged in the rotating support cylinder 62, and the two first wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com