Movable rack cordless circular vertical lifting mechanism

A technology of vertical lifting and moving racks, which is applied in transportation and packaging, elevators in buildings, etc., which can solve the problems of large power and occupied space, few circulation paths, and insufficient practicability, and achieve the increase of the number of car circulation paths, The effect of small building space occupation and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

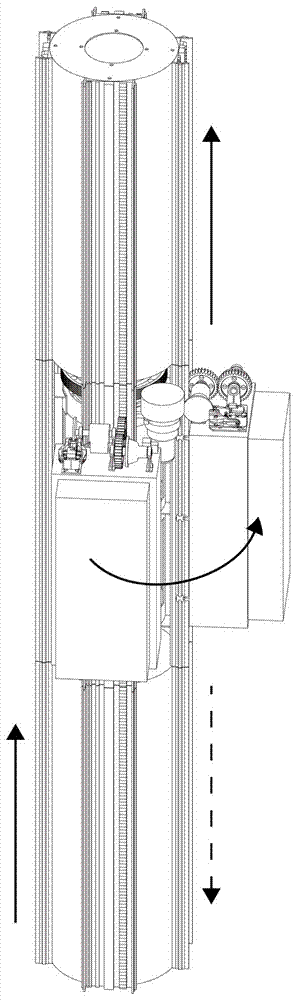

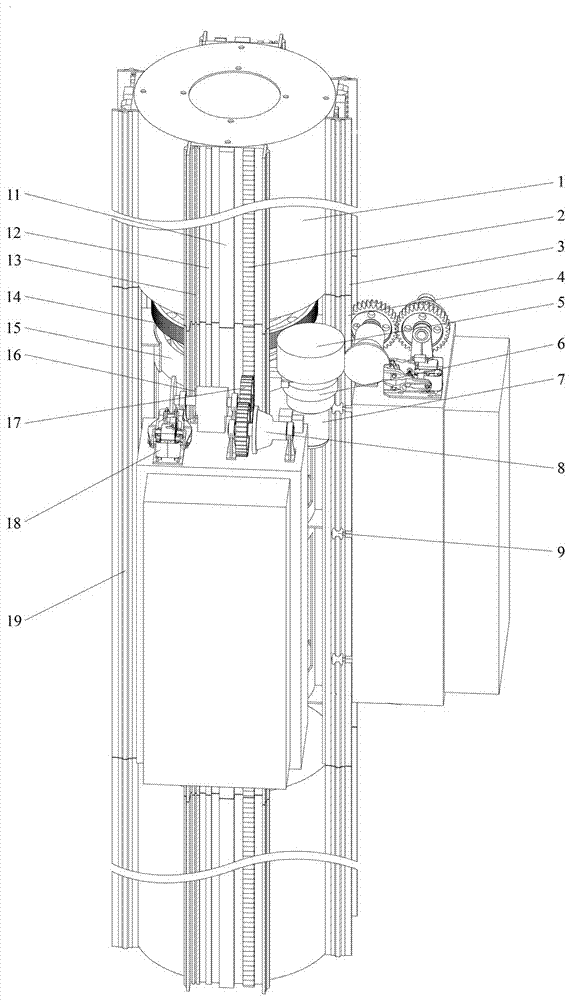

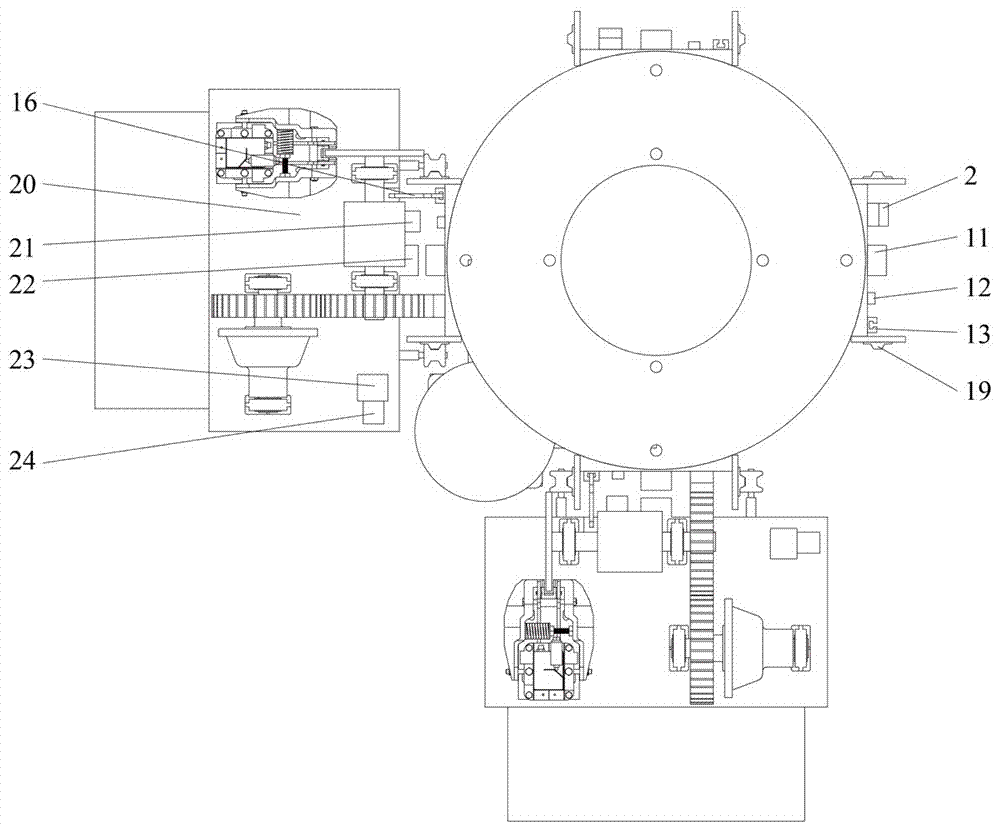

[0032] as attached Figure 1-5 As shown, a mobile frame cordless circulation vertical lifting system includes a horizontal rotating frame 26 rotatably fitted on the fixed shaft 1 . The outer surface of the horizontally rotating frame 26 is provided with a rotating vertical track 4, and the rotating vertical track 4 drives the moving frame 20 to move along the rotating vertical track 4 through the driving device, and moves along the rotating vertical track 4 through the moving frame 20, and the moving frame 20 moves along the rotating vertical track 4. Rotating frame 26 rotates horizontally, constitutes the vertical lifting of mobile frame cordless circulation.

[0033] The present invention is provided with the structure that the vertical track 4 is rotated on the outer surface of the horizontally rotating frame 26, which can make the horizontally rotating frame 26 very compact, that is, the diameter of the horizontally rotating frame 26 can be reduced, and the horizontally ro...

Embodiment 2

[0043] as attached Figure 6 As shown, a cordless circulation vertical lifting system of the mobile frame, the magnetic grid I12 on the fixed vertical track 3 or the rotating vertical track 4, the magnetic head I21 used in conjunction with the magnetic grid I12 on the mobile frame 20, and the magnetic grid II27 on the fixed axis 1 And correspondingly installed on the magnetic head II 28 on the horizontal rotation frame 26 can be transformed into rotary encoder respectively, the function that is carried out is identical, as attached Figure 6 The mover encoder 31 and the turntable encoder 30 are shown. Can all the other structures be with embodiment 1.

Embodiment 3

[0045] as attached Figure 7 As shown, a mobile frame cordless circulation vertical lifting system, the rotating power device of the horizontally rotating frame 26 is replaced by the turntable I29 by the turntable motor 7, the driving gear 5, and the outer ring gear 14. All the other structures are with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap