Excavator suitable for working on slope and capable of controlling bucket based on annular motor

A motor control and excavator technology, applied in the field of buckets, can solve the problems of being unable to adapt to soft soil, hard soil and frozen soil, easy rollover of excavators, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

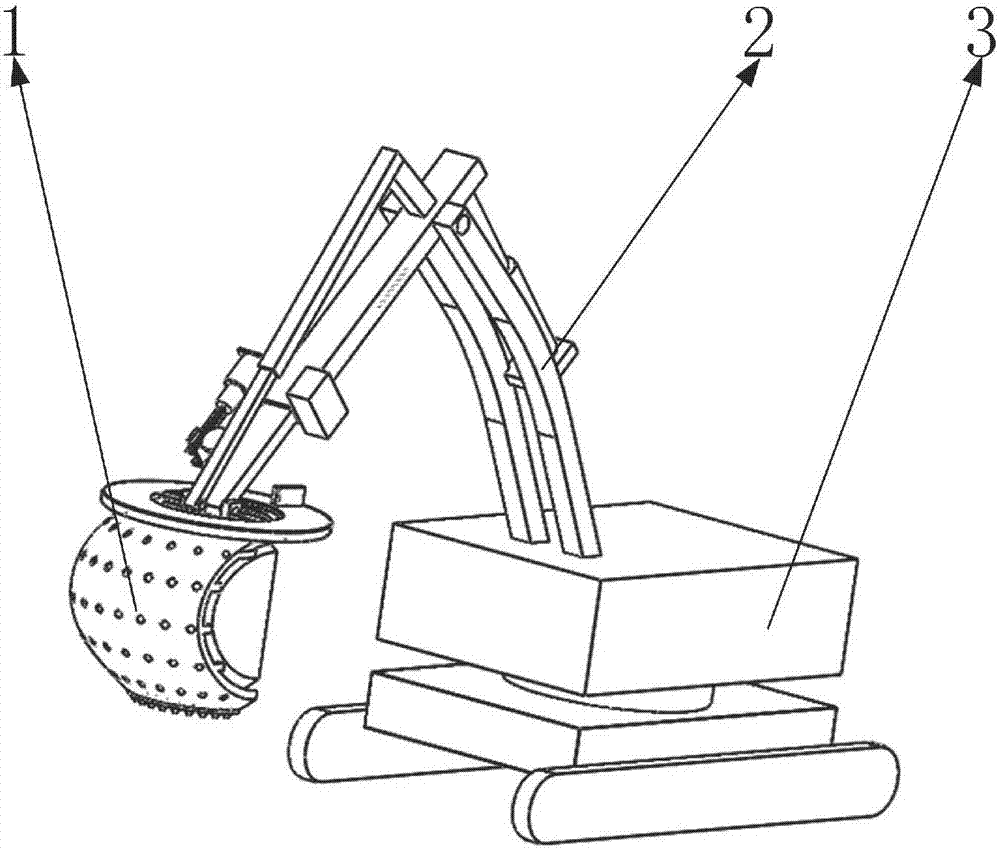

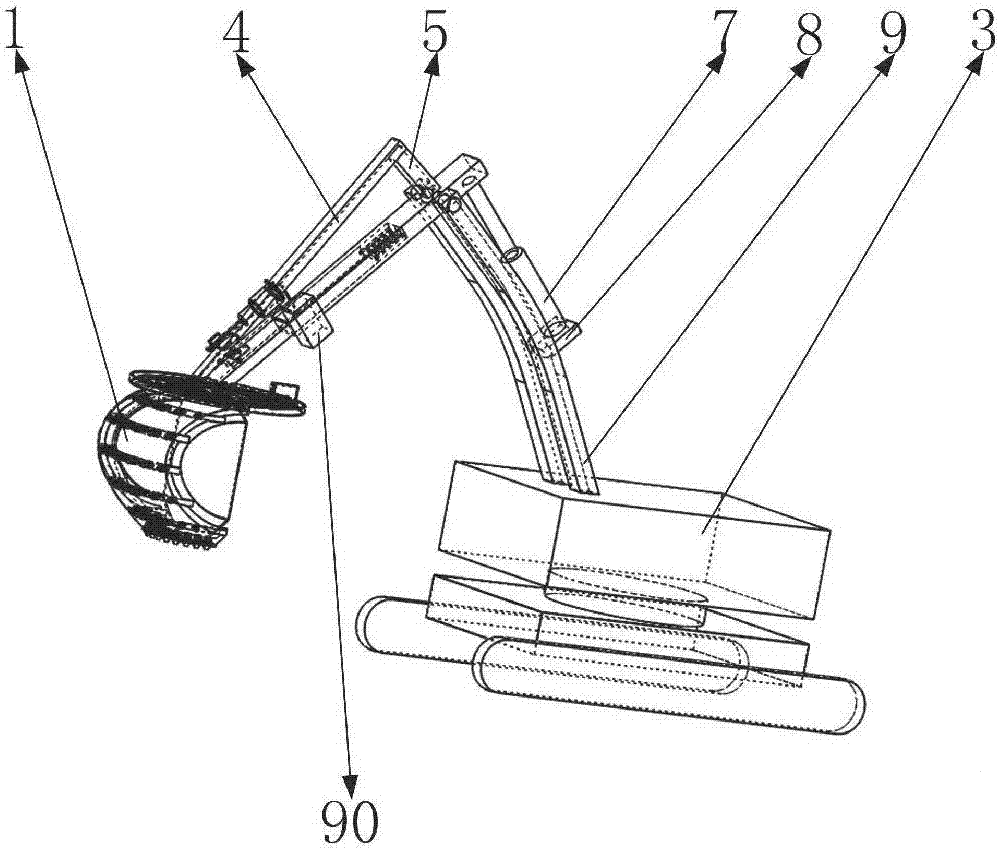

[0058] Such as figure 1 , 2 , 3, it includes bucket mechanism 1, shovel arm mechanism 2, excavator base mechanism 3, such as figure 1 , 2 , 3, wherein the shovel arm mechanism 2 is installed on the upper side of the excavator base mechanism 3; the bucket mechanism 1 is installed at one end of the shovel arm mechanism 2.

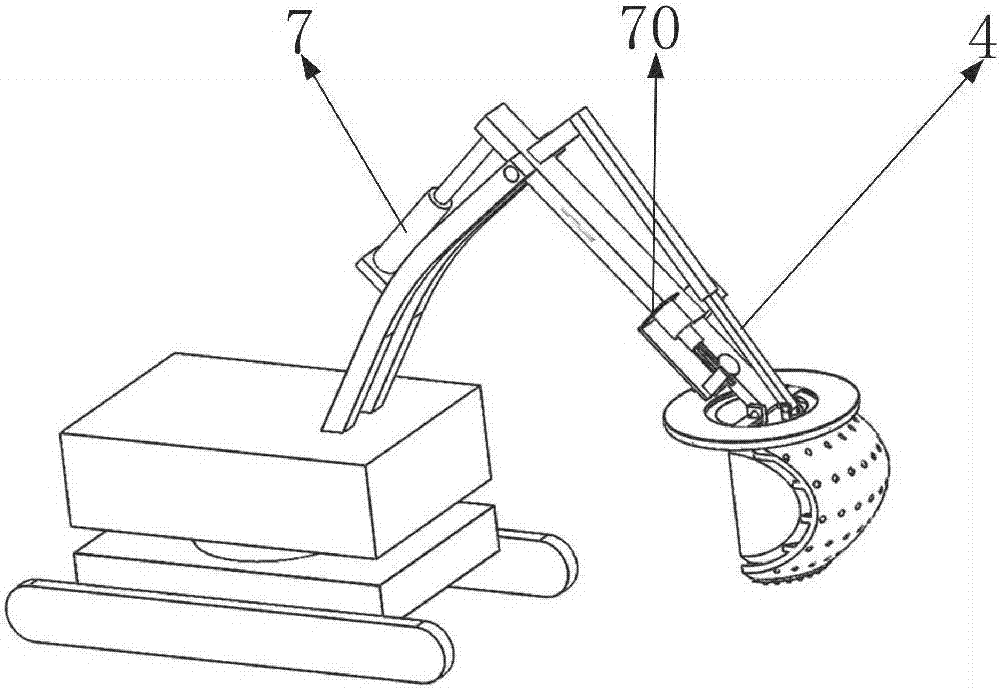

[0059] Such as Figure 4 , 5 As shown, the above-mentioned shovel arm mechanism 2 includes a first hydraulic cylinder 4, a hydraulic tank 90, a push circular plate 89, a first fixed block 5, a second hydraulic cylinder 7, a second fixed block 8, a support arm 9, a telescopic arm 16, Telescopic shell 17, chute 19, return spring 20, hydraulic rod 67, first oil chamber 68, hydraulic cylinder shell 69, first fixed plate 70, second oil chamber 71, slide block 77, long guide groove 80, such as image 3 As shown, two support arms 9 are symmetrically installed on one end of the upper side of the excavator base mechanism 3; as figure 2 As shown, the second fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com