Pitching device for a large arm of a steering machine

A technology of pitching device and steering machine, which is applied in the field of dumper unloading, can solve the problems of oil pollution, short service time, and large impact of the steering machine, and achieve the effects of enhanced stability, simple structure, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

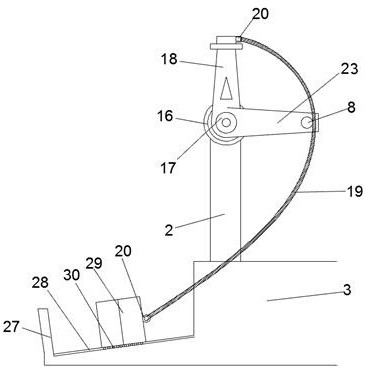

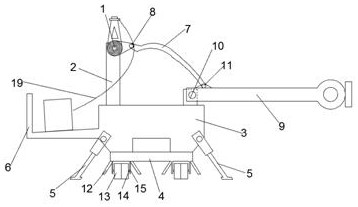

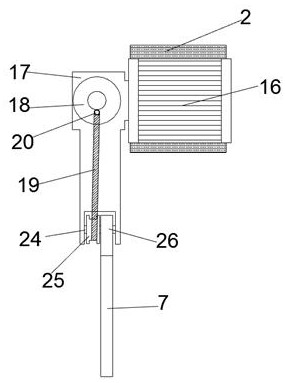

[0015] A tilting device for a large arm of a steering machine, comprising a driving device 1, a driving support arm 2, a vehicle body 3, a load-carrying frame 4, a hydraulic support column 5 at the bottom of a side vehicle, a counterweight device 6, an arc-shaped pull rod arm 7, and a multi-purpose connection Pulley shaft 8, long arm 9, long arm rotation support structure 10, double arm connecting shaft 11, wheel skirt 12, double wheels 13, wheel axle 14, wheel frame 15, and the car body 3 is arranged on the top surface of the bearing frame 4 , the wheel skirt 12, the double wheels 13, the wheel axle 14, and the wheel frame 15 are all provided with two groups, and the wheel frame 15 is symmetrically arranged on the bottom surface of the load-carrying frame 4, and the double wheels 13 are connected by the wheel axle 14 The inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com