Gasoline metering and backflow device with gasoline blocking mechanism

A return device, gasoline technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems affecting the outflow and floating of gasoline, and achieve the effect of high return efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

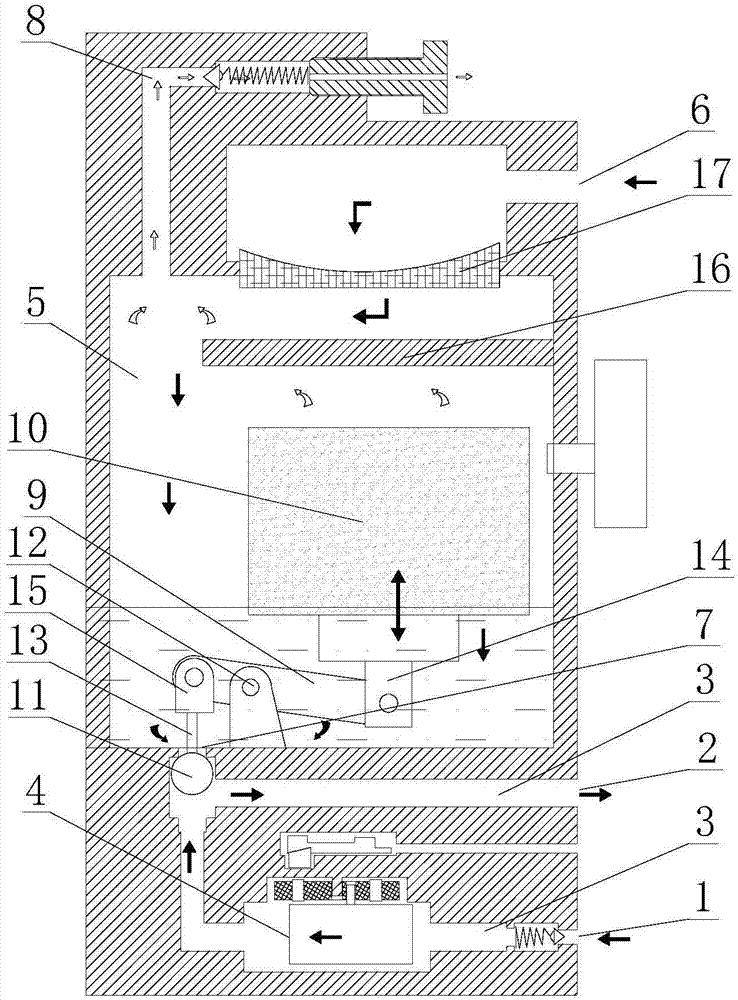

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see figure 1 As shown, the above-mentioned gasoline metering backflow device with a fuel retaining mechanism includes a metering mechanism and a backflow mechanism arranged above the metering mechanism. The metering backflow device is used to accurately measure the refueling amount of a fuel engine.

[0020] The oil from the fuel tank enters the liquid inlet 1 after passing through the coarse filter, and then enters the fine filter through the liquid outlet 2. The filtered oil is sent to the engine for combustion, and the remaining oil passes through the oil return port on the engine And the liquid return port 6 on the first cavity 5 enters the first cavity 5 .

[0021] The metering mechanism includes a liquid inlet 1 connected to the fuel tank, a liquid outlet 2 connected to the engine, an infusion pipeline 3 arranged between the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com