Energy-saving rectifying system for recovering organic solvent

A rectification system and organic solvent technology, applied in the field of energy-saving rectification system, can solve the problems of high energy consumption, and achieve the effects of low energy consumption, convenient reuse, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

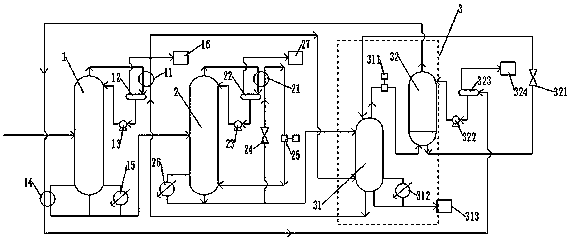

[0020] The reference numerals in the accompanying drawings of the description include: low-pressure column 1, first condenser 11, first reflux buffer tank 12, No. 1 pump 13, reboiler 14, first reboiler 15, first product tank 16, Medium pressure tower 2, second condenser 21, second reflux buffer tank 22, No. 3 pump 23, second throttle valve 24, second heat pump 25, second reboiler 26, second product tank 27, high pressure tower 3. Stripping section 31, rectifying section 32, first heat pump 311, third reboiler 312, fourth product tank 313, first throttle valve 321, No. 3 pump 322, third reflux buffer tank 323, No. Three product tanks 324.

[0021] This embodiment takes the separation and recovery of the mixture of organic solvents ether, methanol, toluene and ethylene glycol as an example.

[0022] Such as figure 1 As shown, the energy-saving rectification system for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com