Vascular covered stent bending force and straightening force dynamically testing device and method

A covered stent and dynamic testing technology, which is applied in the direction of testing material strength, measuring devices, instruments, etc. by applying a stable bending force, can solve problems such as low efficiency and poor test stability, and achieve high accuracy, high reliability, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

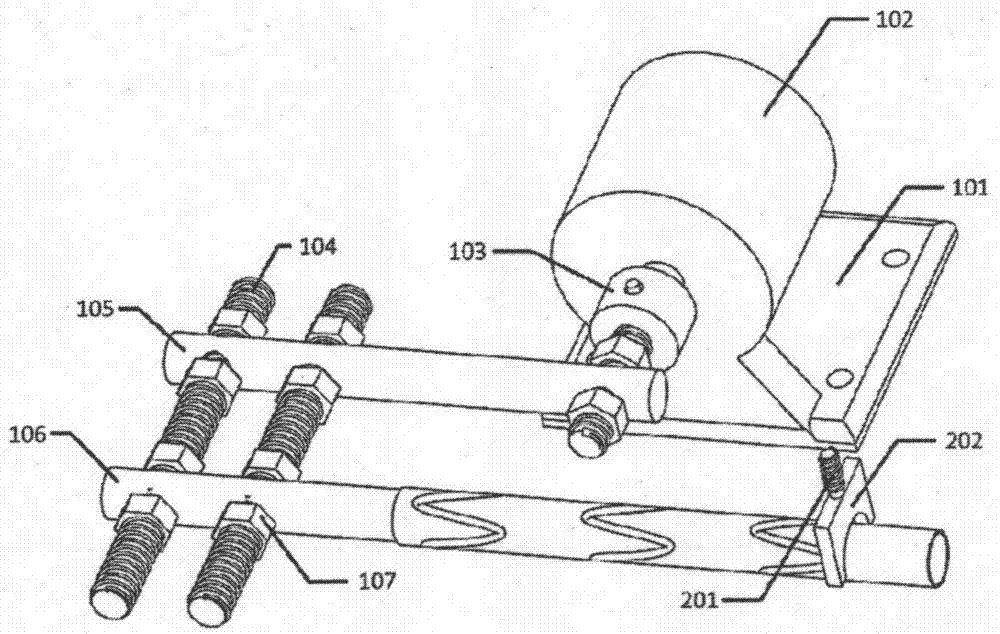

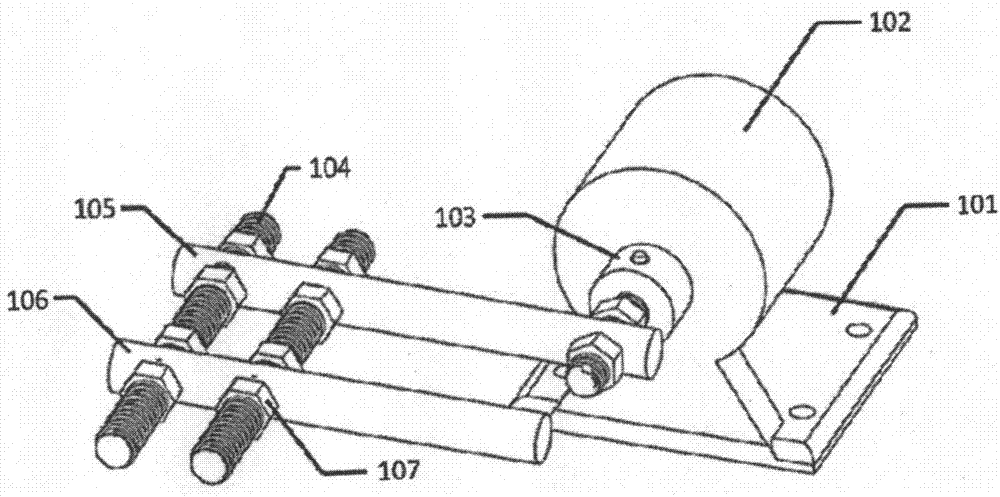

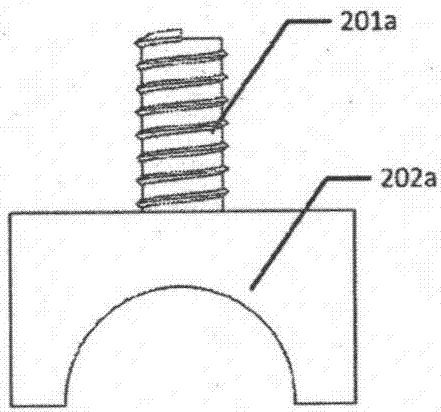

[0042] figure 1 This is a schematic diagram of a dynamic test device for the bending force and rectilinear force of the vascular stent graft. The dynamic test device for the bending force and rectilinear force of the vascular stent graft includes a device for loading the stent graft and realizing the dynamic bending and recoil of the stent graft. Straight bending force and return force test components; and a special-shaped force test indenter used to simulate the contact of the vascular stent graft in the body with the host vessel.

[0043] Combine figure 2 , The bending force and return force test assembly consists of the part holder 101, the miniature synchronous slow-speed motor 102, the fixed part 103 for connecting the motor, the threaded connecting rod 104, the smooth connecting rod 105, the smooth sample loading rod 106 and the fixed position nut 107, etc. composition.

[0044] The miniature synchronous slow-speed motor 102 is fixed on the component fixing base 101. One en...

Embodiment 2

[0061] figure 1 This is a schematic diagram of a dynamic test device for the bending force and rectilinear force of the vascular stent graft. The dynamic test device for the bending force and rectilinear force of the vascular stent graft includes a device for loading the stent graft and realizing the dynamic bending and recoil of the stent graft. Straight bending force and return force test components; and a special-shaped force test indenter used to simulate the contact of the vascular stent graft in the body with the host vessel.

[0062] Combine figure 2 , The bending force and return force test assembly consists of the part holder 101, the miniature synchronous slow-speed motor 102, the fixed part 103 for connecting the motor, the threaded connecting rod 104, the smooth connecting rod 105, the smooth sample loading rod 106 and the fixed position nut 107, etc. composition.

[0063] The miniature synchronous slow-speed motor 102 is fixed on the component fixing base 101. One en...

Embodiment 3

[0079] figure 1 This is a schematic diagram of a dynamic test device for the bending force and rectilinear force of the vascular stent graft. The dynamic test device for the bending force and rectilinear force of the vascular stent graft includes a device for loading the stent graft and realizing the dynamic bending and recoil of the stent graft. Straight bending force and return force test components; and a special-shaped force test indenter used to simulate the contact of the vascular stent graft in the body with the host vessel.

[0080] Combine figure 2 , The bending force and return force test assembly consists of the part holder 101, the miniature synchronous slow-speed motor 102, the fixed part 103 for connecting the motor, the threaded connecting rod 104, the smooth connecting rod 105, the smooth sample loading rod 106 and the fixed position nut 107, etc. composition.

[0081] The miniature synchronous slow-speed motor 102 is fixed on the component fixing base 101. One en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com