Pulse powder outlet mechanism

A pulse type and powder cartridge technology, applied in the field of pulse type powder discharge mechanism, can solve the problems of high powder dispersion requirements, final product impact, powder outlet blockage, etc., to solve powder crystallization agglomeration and control powder discharge volume, to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

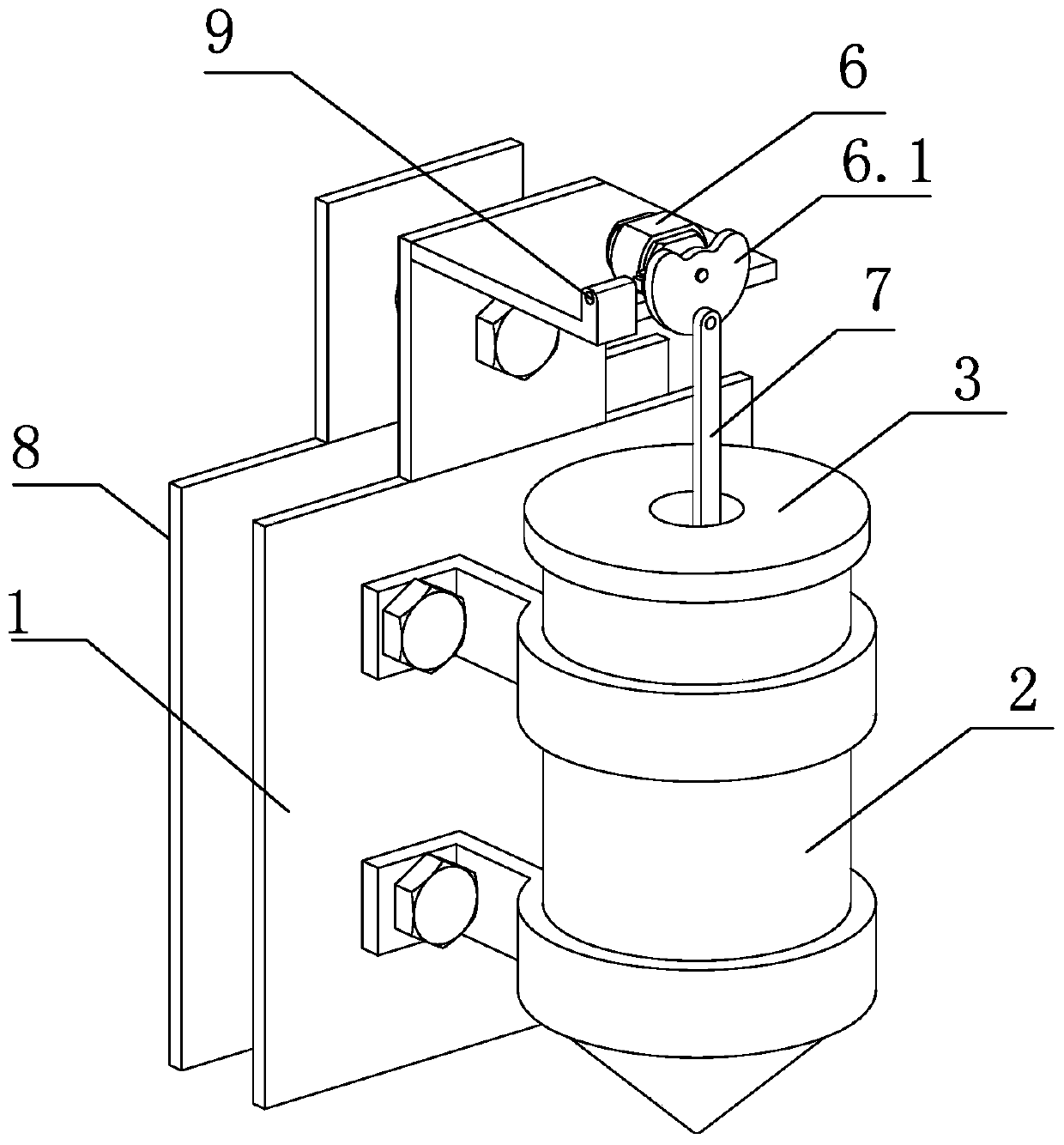

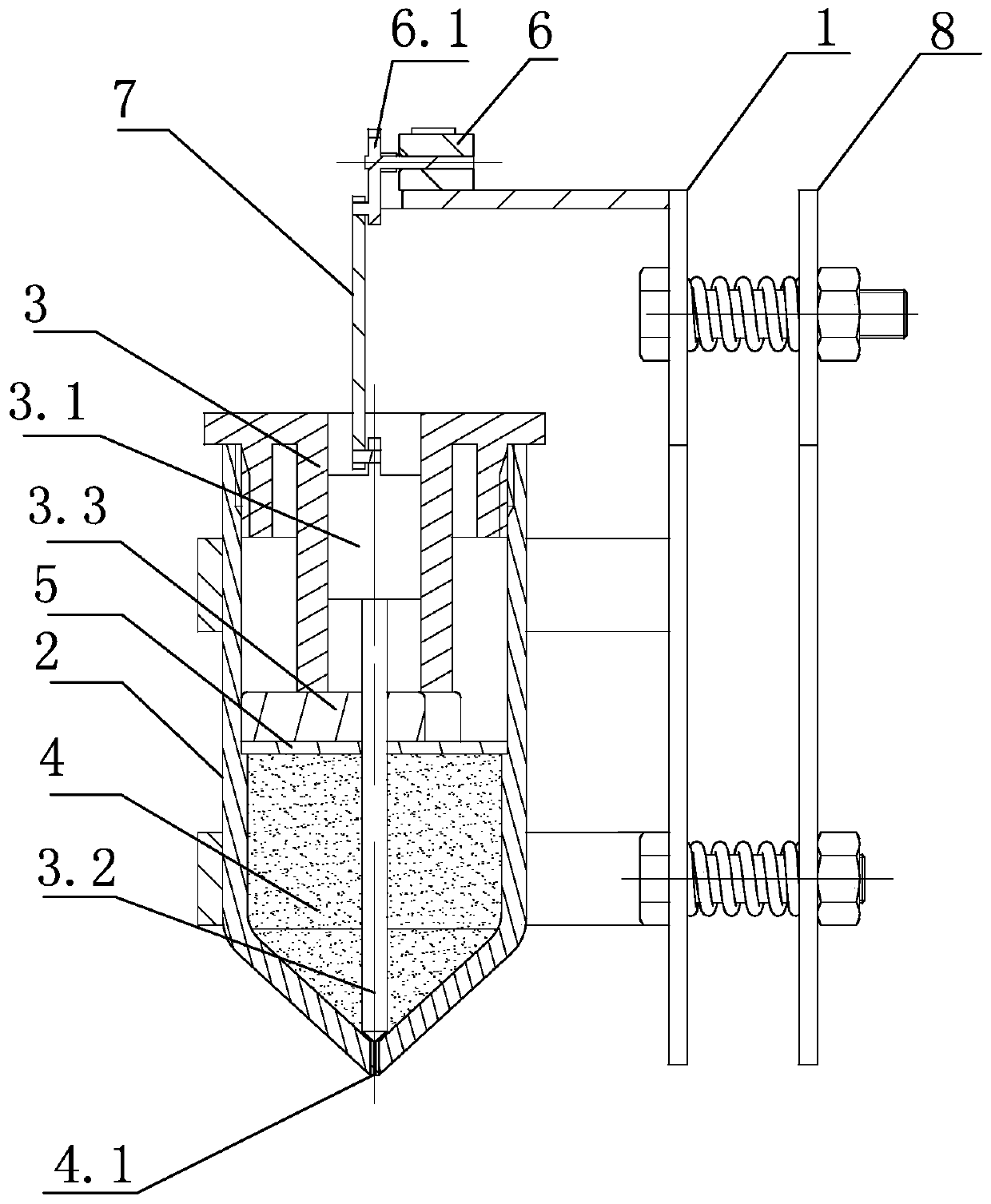

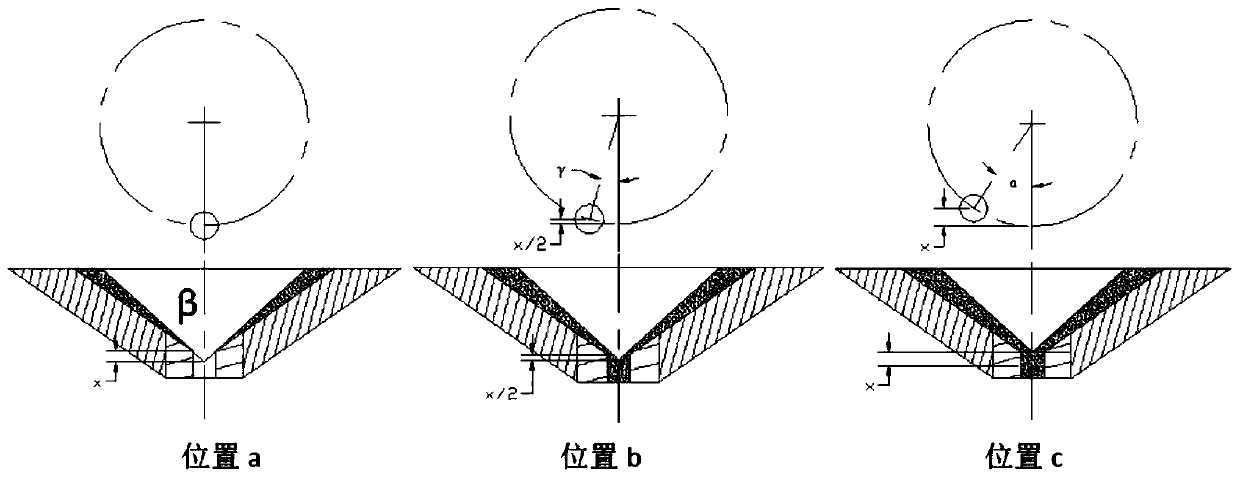

[0022] like Figure 1-2 As shown, a pulse type powder outlet mechanism includes a powder outlet cylinder 2 fixed on the back plate 1, a slide rail 3 is arranged inside the powder outlet cylinder 2, and the inside of the powder outlet cylinder 2 is located on the slide rail 3 The bottom of the slide rail 3 is provided with a powder storage chamber 4; the slide rail 3 is provided with a slider 3.1; the lower end of the slide block 3.1 is provided with a thimble 3.2 extending into the powder storage chamber 4; There is a guide member 3.3 that guides the thimble 3.2; Figure 5 As shown, the guide 3.3 can be a star structure with guide holes. A sealing sheet 5 penetrated by the thimble 3.2 is provided between the guide 3.3 and the powder storage chamber 4; a powder outlet hole 4.1 coaxial with the thimble 3.2 is provided at the bottom of the powder storage chamber 4; The backboard 1 is provided with a stepping motor 6 for driving the slider 3.1; the rotating shaft of the stepping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com