Wiper power transmission assembly scratch angle and tooth gap detection device and method

A power transmission and detection device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of not being able to meet the accuracy requirements of the wiper angle, the detection efficiency of the angle and backlash is not high enough, and the error prevention function is not available. Achieve the effect of capturing accurately, solving practical problems, and ensuring accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

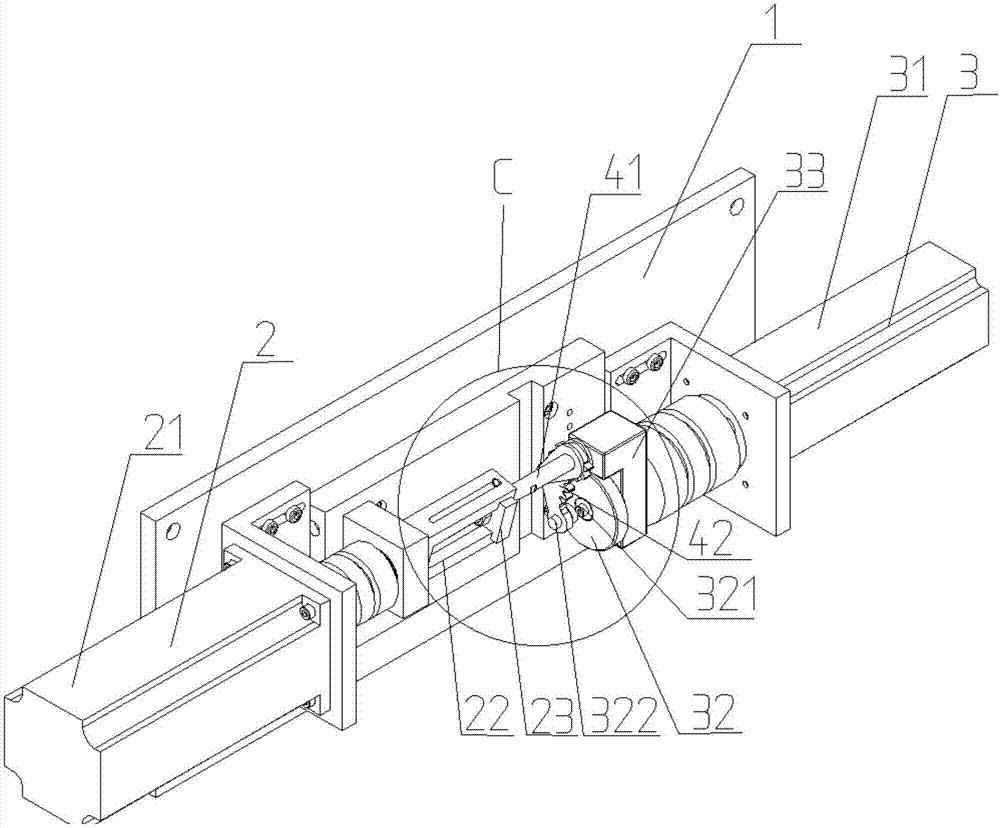

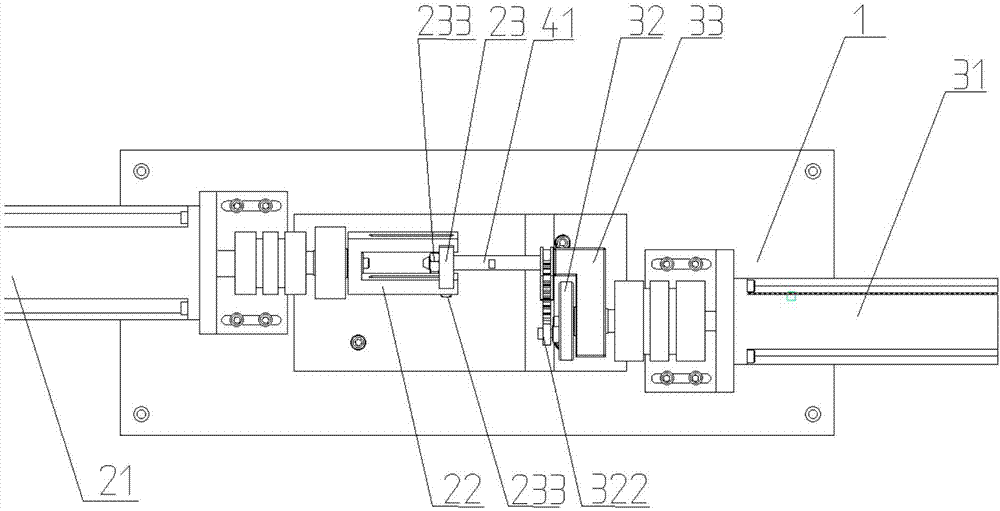

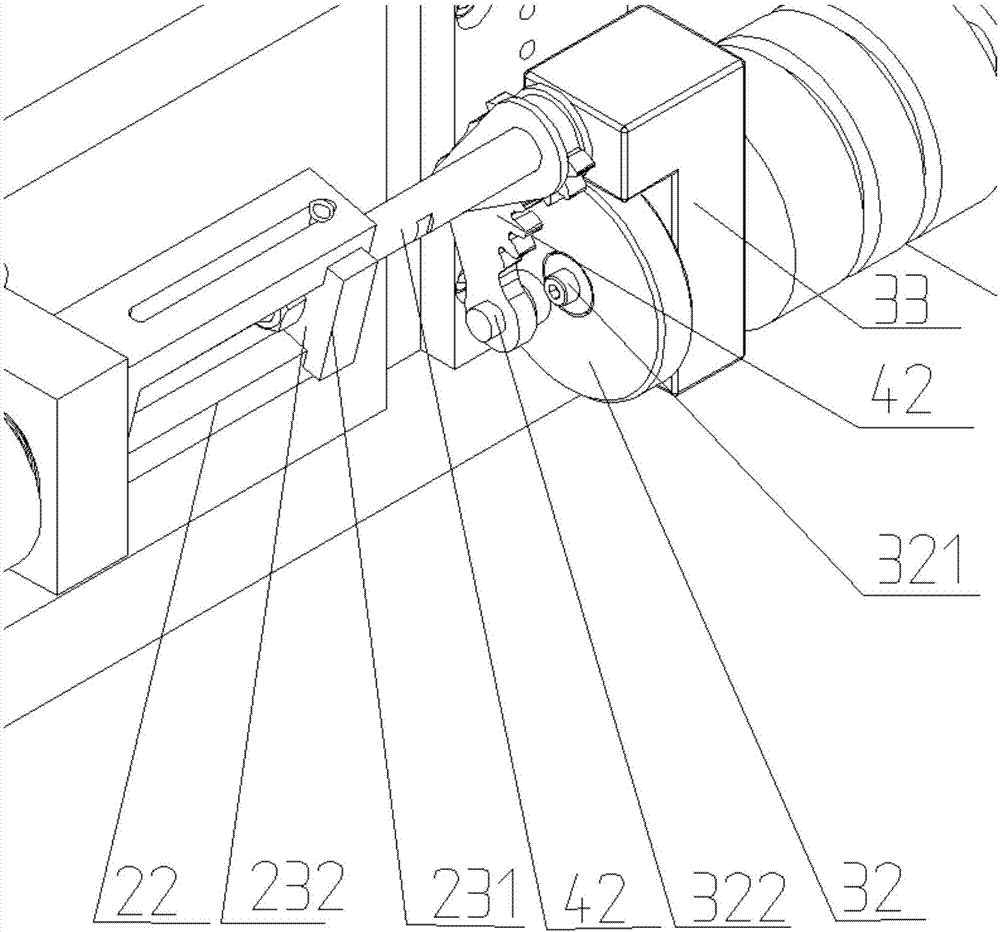

[0035] Such as figure 1 and figure 2 As shown, a scraping angle and backlash detection device of a wiper power transmission assembly includes a bottom plate 1, a first rotating device 2 and a second rotating device 3, and the first rotating device 2 and the second rotating device 3 are connected with each other. The bottom plate 1 is relatively fixed, the first rotating device 2 includes a first motor 21 with encoder feedback and a fixing device, and the fixing device is used to connect the power output shaft 41 of the wiper power transmission assembly with the encoder feedback The shaft of the first motor 21 is relatively fixed; the second rotating device 3 includes a second motor 31 with encoder feedback and a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com