A comprehensive evaluation method of high-speed press structure scheme

A comprehensive evaluation and press technology, applied in the field of presses, can solve problems such as resonance, high-speed press collapse, and damage to key components of high-speed presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

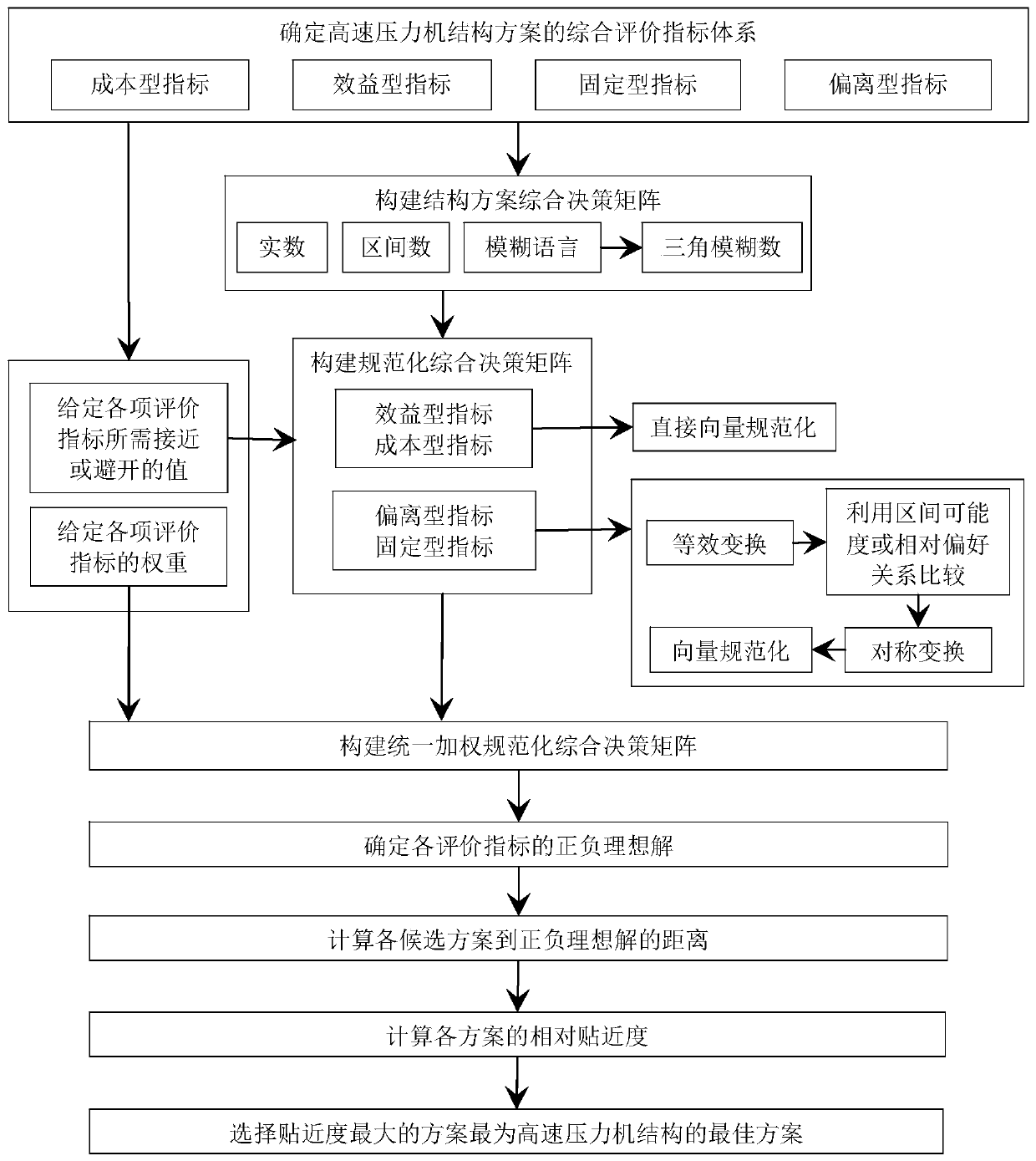

Method used

Image

Examples

Embodiment Construction

[0031] The structural scheme of the high-speed press of the present invention is preferably a high-speed press with a nominal force of 3000kN and a stamping frequency of 80-240spm as an example. Therefore, in the design process of high-speed presses, the maximum deformation of the slider needs to be as small as possible, and the strength of the upper beam must be ensured so that the maximum equivalent stress is less than [60,61] MPa. At the same time, during the stamping process of the slider at a stamping frequency of 80-240spm, its low-order natural frequency should avoid the range of 1.33-4Hz to prevent resonance. Considering that resonance may also occur when the natural frequency of the slider is close to the working frequency of 50Hz, it is also necessary to avoid this frequency range. In addition, the structural manufacturability of the entire high-speed press has an important impact on its production cost, and it is also used as one of the evaluation indicators. It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com