Printing method of printed matter with radial laser 3D pattern

A printing method and radial technology, applied in the field of printed matter, can solve the problems of poor anti-counterfeiting effect, insufficient decoration effect, single form of expression, etc., and achieve the effect of highlighting the effect of decoration and marking and highlighting the effect of anti-counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

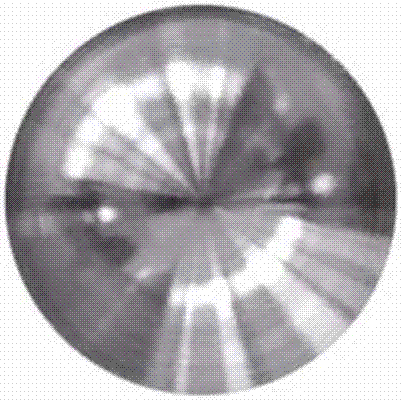

[0028] The embodiment of the present invention provides a printed matter with a radial laser 3D pattern, which includes laser paper as the printing substrate, and a flat mesh yellow bottom layer that is hot-stamped on the laser paper with a cat's eye holographic layer printed sequentially from the inside to the outside, The red tone layer in the middle of the pattern level, the black tone enhancement layer of the pattern level, and then the anodized aluminum layer with hot lines, and finally the pattern embossing process. specific:

[0029] Laser paper is used as the printing substrate. This layer provides the basic support material for the packaging of printed matter. The laser layer on the surface has a certain penetrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com