Film multi-layer three-dimensional pattern anti-counterfeiting printing process with prism refraction function

A technology of prism refraction and anti-counterfeiting printing, which is applied in the printing process, printing, printing of special varieties of printed matter, etc., can solve the problems of no anti-counterfeiting function, difficulty in effectively protecting consumers' rights and interests, and single anti-counterfeiting function, so as to improve anti-counterfeiting Aging performance, good anti-counterfeiting effect, and effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

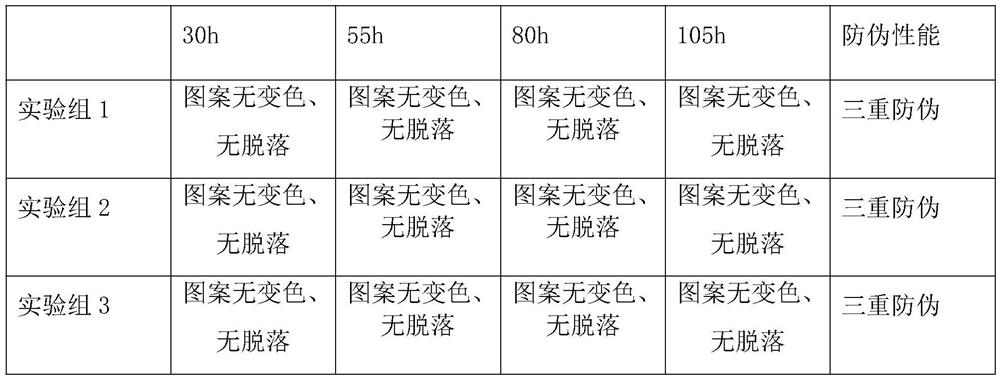

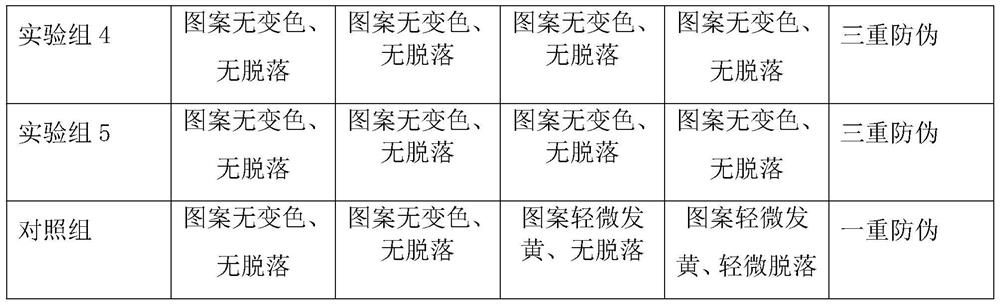

Examples

Embodiment 1

[0024] The invention provides a film multi-layer three-dimensional pattern anti-counterfeiting printing process with prism refraction function, comprising the following steps:

[0025] Step 1: Design of anti-counterfeiting patterns, according to the user's product characteristics and anti-counterfeiting requirements, use computer image processing software to design multiple anti-counterfeiting patterns that can meet product feature requirements;

[0026] Step 2: Send the anti-counterfeiting pattern designed by the computer software in step 1 to the CTP plate distributor, and use the CTP plate distributor to make plates to obtain printing plate A and printing plate B;

[0027] Step 3: Put the printing plate A and printing plate B obtained in step 2 into the UV printer, and use the UV printer to print the film with prism refraction function. The UV printer uses anti-counterfeiting ink A and anti-counterfeiting ink B for three-layer composite After printing, a film with multi-lay...

Embodiment 2

[0039] The invention provides a film multi-layer three-dimensional pattern anti-counterfeiting printing process with prism refraction function, comprising the following steps:

[0040] Step 1: Design of anti-counterfeiting patterns, according to the user's product characteristics and anti-counterfeiting requirements, use computer image processing software to design multiple anti-counterfeiting patterns that can meet product feature requirements;

[0041] Step 2: Send the anti-counterfeiting pattern designed by the computer software in step 1 to the CTP plate distributor, and use the CTP plate distributor to make plates to obtain printing plate A and printing plate B;

[0042] Step 3: Put the printing plate A and printing plate B obtained in step 2 into the UV printer, and use the UV printer to print the film with prism refraction function. The UV printer uses anti-counterfeiting ink A and anti-counterfeiting ink B for three-layer composite After printing, a film with multi-lay...

Embodiment 3

[0054] The invention provides a film multi-layer three-dimensional pattern anti-counterfeiting printing process with prism refraction function, comprising the following steps:

[0055] Step 1: Design of anti-counterfeiting patterns, according to the user's product characteristics and anti-counterfeiting requirements, use computer image processing software to design multiple anti-counterfeiting patterns that can meet product feature requirements;

[0056] Step 2: Send the anti-counterfeiting pattern designed by the computer software in step 1 to the CTP plate distributor, and use the CTP plate distributor to make plates to obtain printing plate A and printing plate B;

[0057] Step 3: Put the printing plate A and printing plate B obtained in step 2 into the UV printer, and use the UV printer to print the film with prism refraction function. The UV printer uses anti-counterfeiting ink A and anti-counterfeiting ink B for three-layer composite After printing, a film with multi-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com