Color invisible pattern element and preparation method thereof

An invisible and patterned technology, applied in optical elements, polarizing elements, optics, etc., can solve problems such as liquid crystal alignment disorder, loss of hidden meaning, invisible pattern leakage, etc., to achieve high value, good anti-counterfeiting effect, and beautiful product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A second aspect of the present invention provides a method for preparing the colored invisible pattern element as described above, comprising the following steps:

[0060] S1: coating a photosensitive alignment layer material on a substrate with a reflective layer, and drying;

[0061] S2: Exposing different regions of the photosensitive alignment layer with linearly polarized ultraviolet light with different wave vectors, so that the molecules of the photosensitive alignment layer material have different pretilt angles;

[0062] S3: applying a nematic liquid crystal layer material to different regions of the photosensitive alignment layer, drying, and aligning the liquid crystal molecules;

[0063] S4: curing the nematic liquid crystal layer to obtain the color invisible pattern element.

Embodiment 1

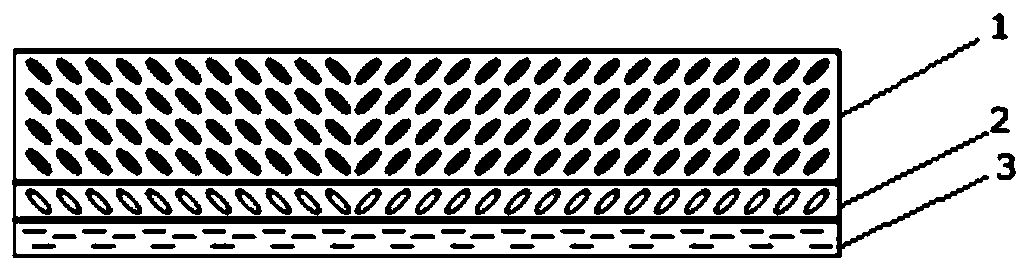

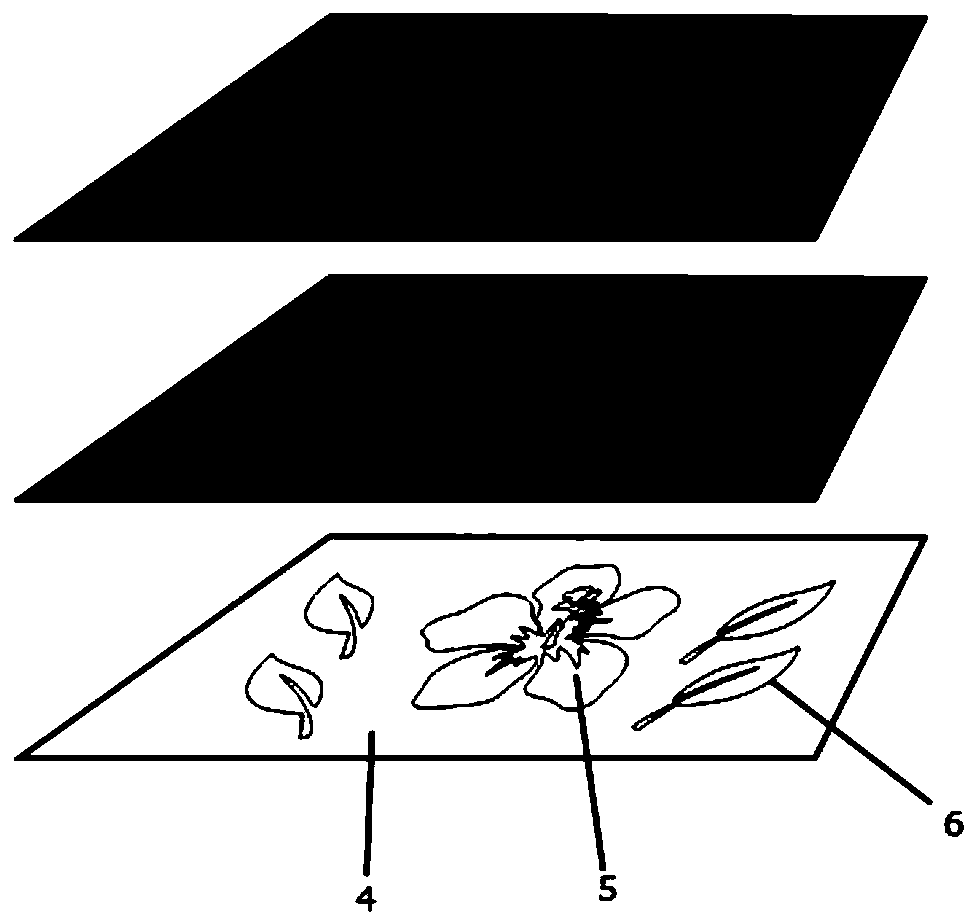

[0066] Example 1 : see figure 1 and 2 As shown, embodiment 1 provides a kind of color invisible pattern element, and described color invisible pattern element comprises nematic phase liquid crystal layer 1, photosensitive alignment layer 2 and reflective layer 3, and described photosensitive alignment layer 2 is arranged on described reflective layer 3 and the nematic liquid crystal layer 1; the photosensitive alignment layer 2 includes up to three regions with different molecular pretilt angles relative to the plane of the reflective layer 3 . Wherein the reflective layer 3 is aluminized PET.

[0067] The colored invisible pattern element is prepared by the following method, which specifically includes the following steps:

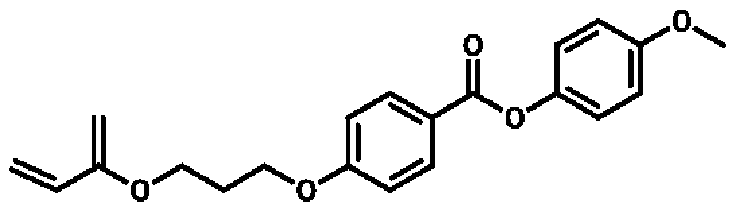

[0068] Preparation of nematic liquid crystal layer material: by weight, add 2 parts of photoinitiator (IRGACURE369) to the mixed nematic liquid crystal material composed of 75 parts of liquid crystal molecules I, 10 parts of liquid crystal molecules I...

Embodiment 2

[0075] Example 2: see figure 1 and 2 As shown, embodiment 2 provides a kind of color invisible pattern element, and described color invisible pattern element comprises nematic phase liquid crystal layer 1, photosensitive alignment layer 2 and reflective layer 3, and described photosensitive alignment layer 2 is arranged on described reflective layer 3 and the nematic liquid crystal layer 1; the photosensitive alignment layer 2 includes up to three regions with different molecular pretilt angles relative to the plane of the reflective layer 3 . Wherein the reflective layer 3 is a cholesteric liquid crystal layer.

[0076] The colored invisible pattern element is prepared by the following method, which specifically includes the following steps:

[0077] Preparation of nematic liquid crystal layer material: by weight, add 2 parts of photoinitiator (IRGACURE369) to the mixed nematic liquid crystal material composed of 75 parts of liquid crystal molecules I, 10 parts of liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com