Battery grading method

A grading, battery technology, applied in secondary batteries, secondary battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of lithium-ion battery cycle life and other performance degradation, poor internal resistance consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

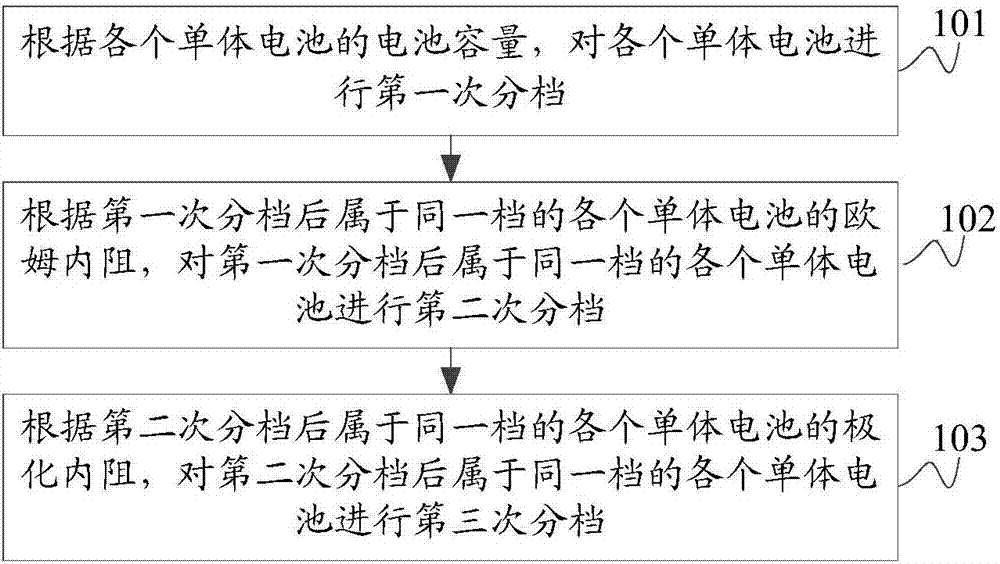

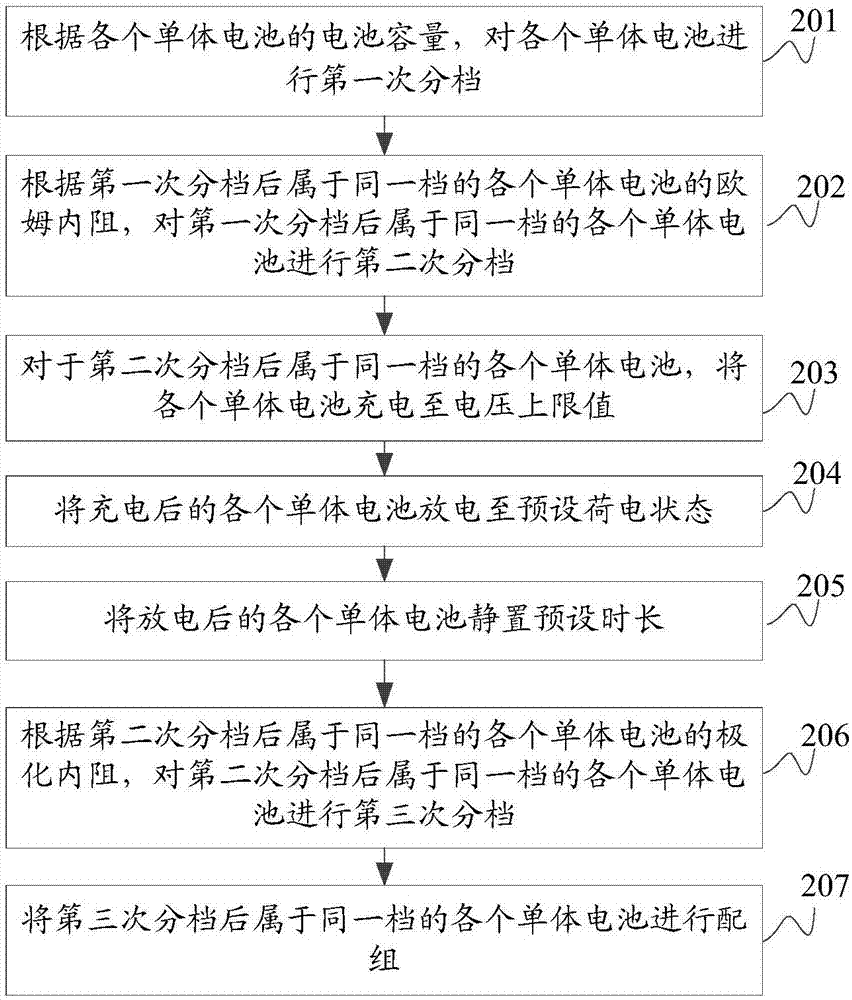

[0041] In order to overcome the problems existing in the related technology, the embodiment of the present invention provides a method for classifying batteries. In addition, according to the polarization internal resistance, the single cells that belong to the same class after two binnings are classified again, so as to simulate the actual use scene of the single cells, so that the single cells in the same class are used for When grouping, the consistency of the internal resistance of the above-mentioned single cells in the same gear is better, thereby improving performance such as the cycle life of each single cell after grouping.

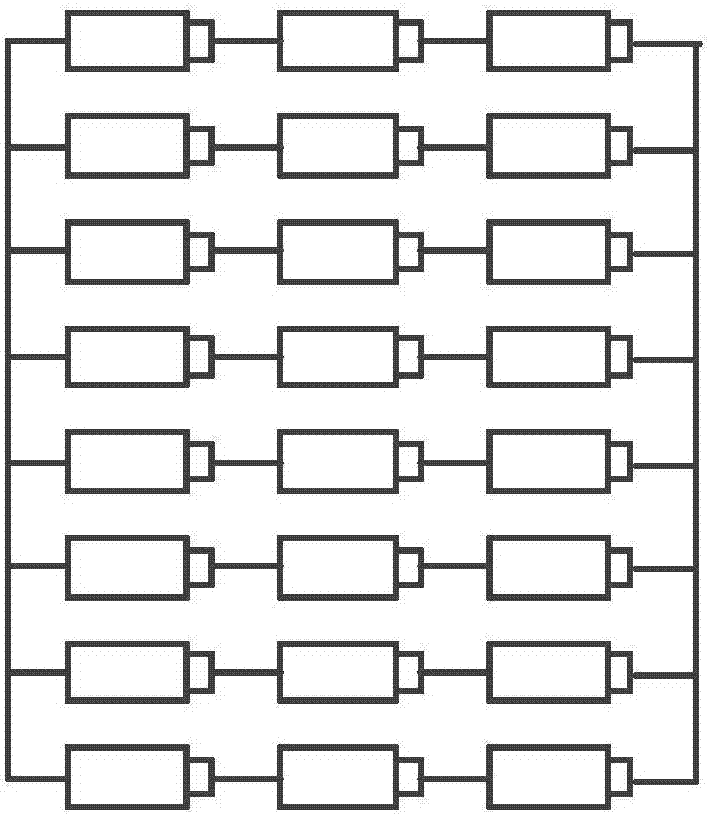

[0042] Among them, a single battery refers to a battery that exists in a single form without internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com