Electric working machine

A working machine, electric technology, applied in the direction of motor control, motor generator control, motor generator testing, etc., can solve the problems of loose front-end tools, unable to generate braking force, unable to fully exert braking function and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below with reference to the drawings.

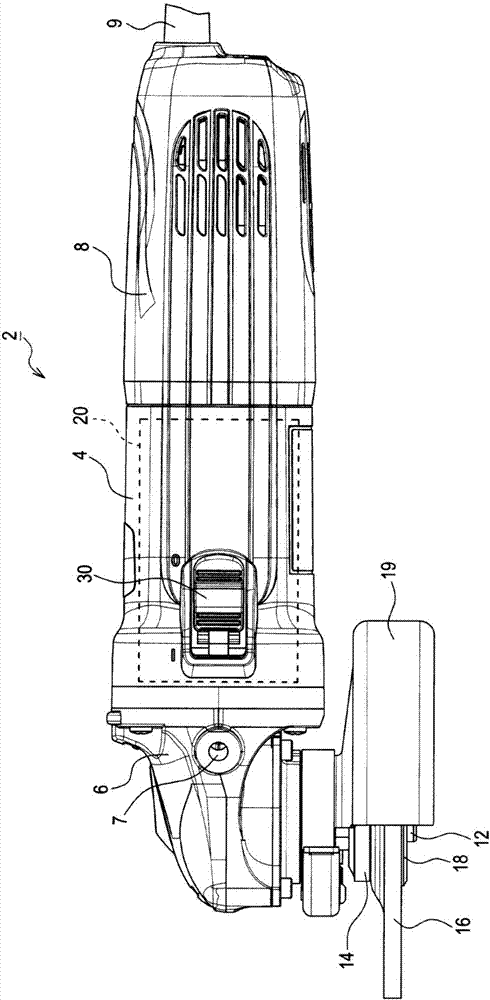

[0025] Such as figure 1 As shown, the grinder 2 of this embodiment is mainly composed of a motor housing 4 , a gear housing 6 , and a rear cover 8 .

[0026] The motor case 4 is a substantially cylindrical case and accommodates the motor 20 . The motor 20 is accommodated in the motor case 4 such that its rotation axis is parallel to the central axis of the motor case 4 , and one end of the rotation shaft protrudes toward the gear case 6 side.

[0027] Further, the rotation shaft of the motor 20 is connected to the main shaft 12 protruding outward from the gear case 6 via a gear mechanism provided in the gear case 6 .

[0028] The main shaft 12 is provided rotatably in the gear case 6 in such a manner that the central axis is perpendicular to the rotation shaft of the motor 20, and the gear mechanism in the gear case 6 is constituted by using bevel gears or the like so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com