Damping system of commercial vehicle

A shock absorber system and commercial vehicle technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as shock absorber failure, hydraulic oil not having a buffering effect, and difficult manufacturing processes. To achieve the effect of prolonging the service life, facilitating rectification and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The present invention will be further described below with reference to the accompanying drawings.

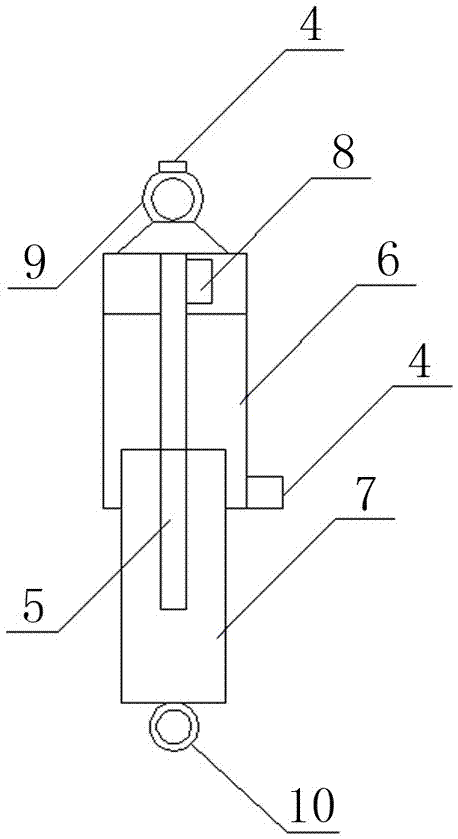

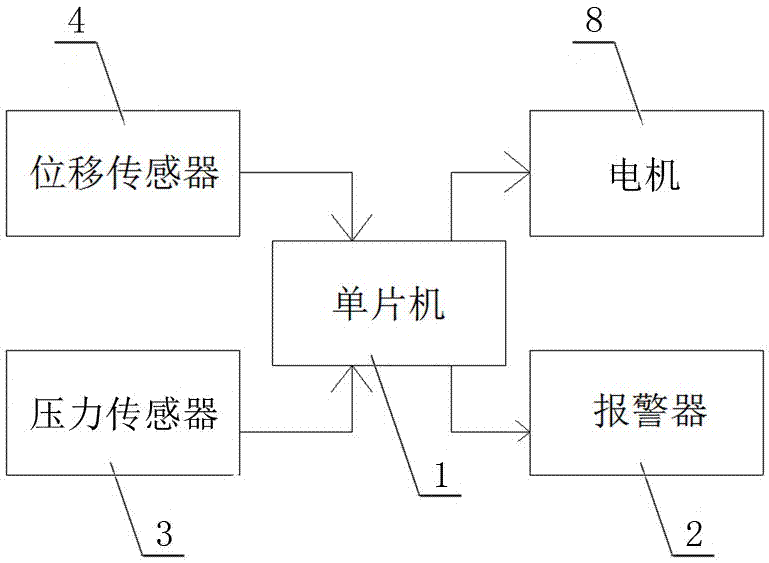

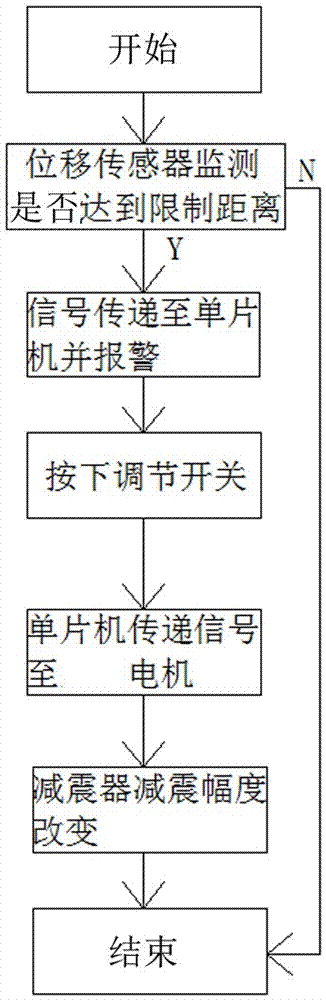

[0015] like figure 1 , figure 2 , image 3 As shown, a shock absorption system for a commercial vehicle includes a single-chip microcomputer 1, an alarm 2, a pressure sensor 3, two displacement sensors 4, and a hydraulic shock absorber; the hydraulic shock absorber is a piston rod length variable hydraulic shock absorber The device includes a piston rod 5 and a first cavity 6, a second cavity 7 is arranged in the first cavity 6, a motor 8 is arranged on the top of the first cavity 6, and a gear is arranged on the output shaft of the motor 8 , a rack is meshed outside the gear, the lower end of the rack is fixedly connected with the upper end of the piston rod 5, the lower end of the piston rod 5 is inserted into the second cavity 7, and the lower end of the second cavity 7 is provided with a second connection Ring 10, a first connecting ring 9 is provided on the uppe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap