A self-leaking bucket with reset function based on centrifugal principle

A bucket and functional technology, applied in the field of self-leaking buckets, can solve problems such as unfavorable excavator work and reduced excavator work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

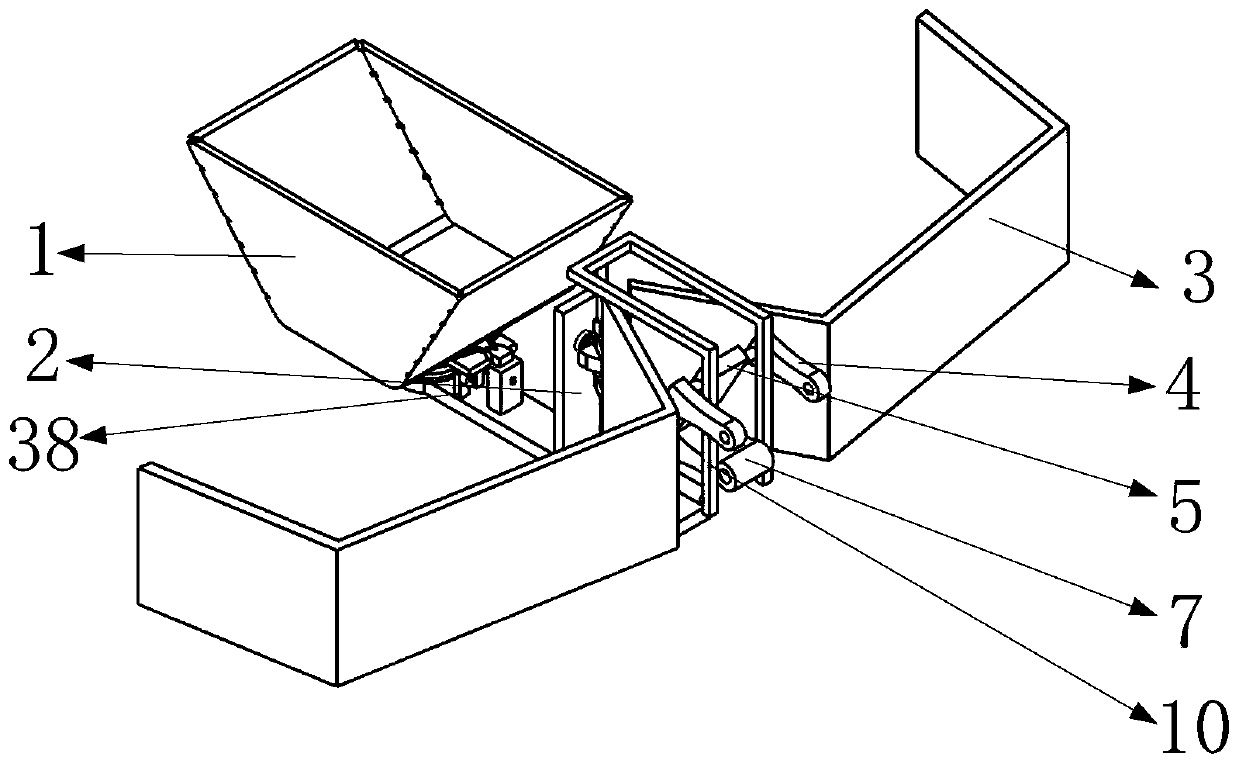

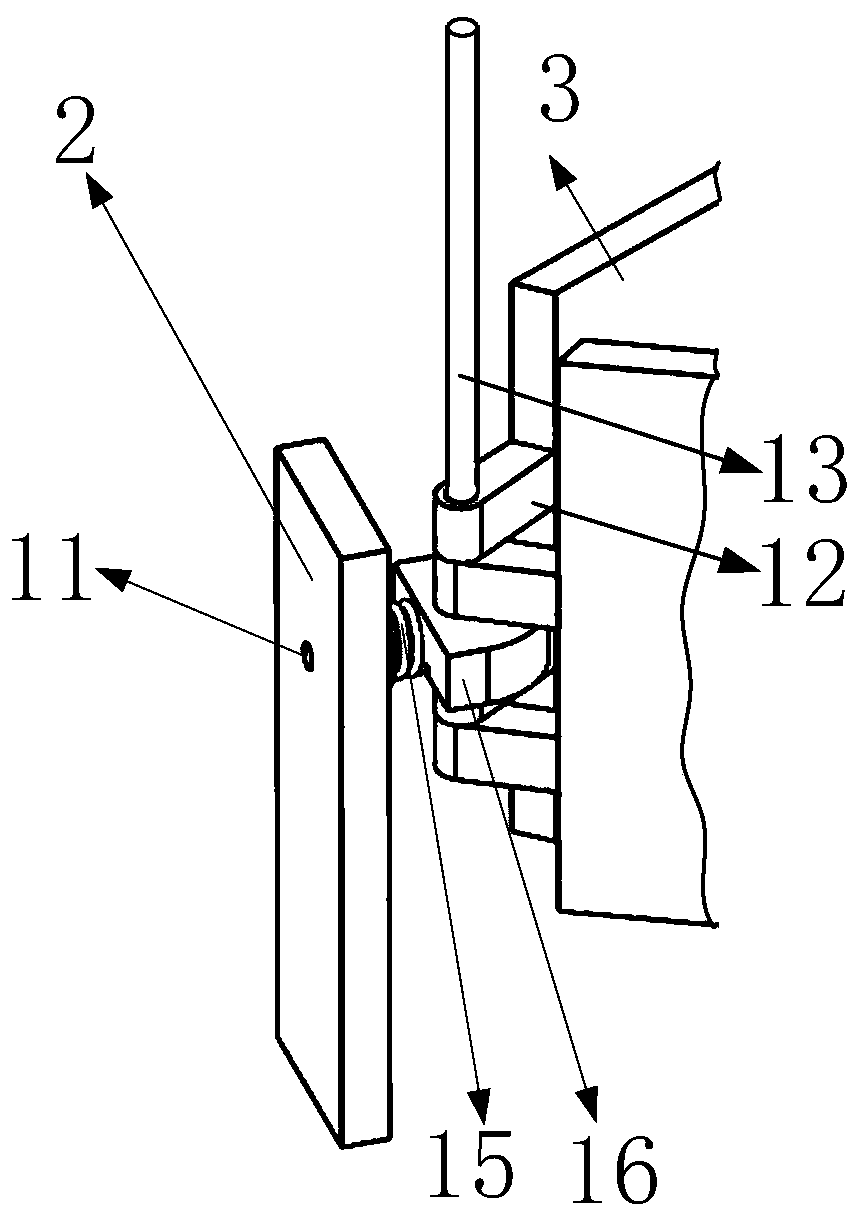

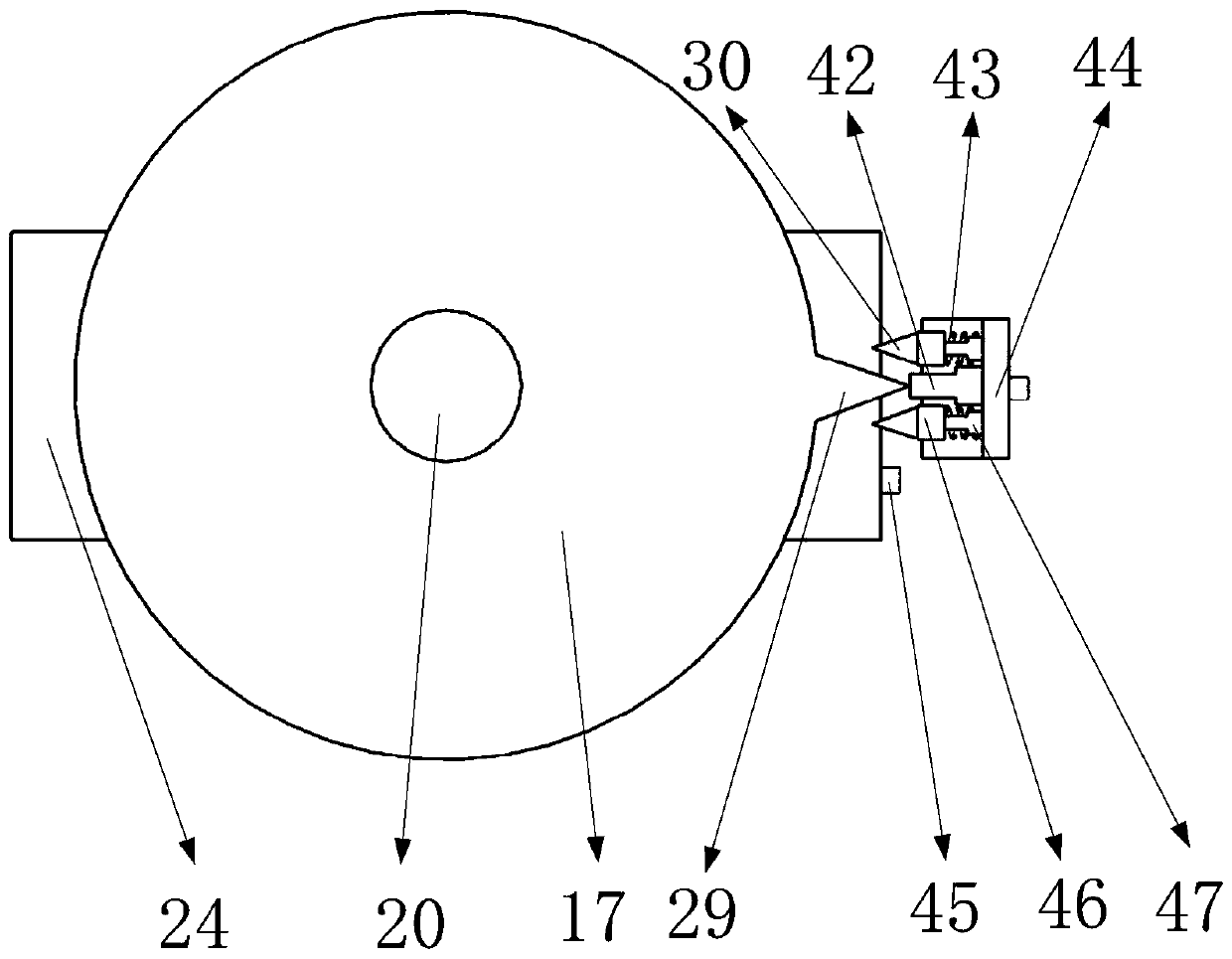

[0032] Such as figure 1 As shown, it includes bucket body 1, mounting plate 2, bucket lug 4, fixed plate 5, lug connecting pin 6, hook 7, connecting plate 8, swing shaft 11, limit rod block 18, card Block groove 19, transmission shaft 20, limit rod 21, center rod 22, return spring 23, hydraulic motor 24, water leakage hole 25, hydraulic oil storage block 26, hydraulic cylinder oil outlet hole 27, stop ring 28, first oil inlet pipe 31. Oil outlet stopper 32, storage block oil outlet 33, hydraulic oil storage cavity 34, storage block oil inlet 35, swing mechanism 39, water retaining mechanism 40, bucket body reset mechanism 46, among which figure 1 , 5 As shown, the bucket lug 4 is installed on the bucket arm, and the lug connecting pin 6 is installed between the two bucket lugs 4; Figure 4 As shown, one end of the fixed plate 5 is installed on the lug cylindrical pin 49, and the other end is equipped with a connecting plate 8; the hook 7 is installed on the fixed plate 5; as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com