Spacecraft propellant management method

A management method and propellant technology, applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems of reducing the carrying capacity of the spacecraft and increasing the structural mass of the spacecraft, to meet the requirements of multiple starts, simplify the Control system design to ensure the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

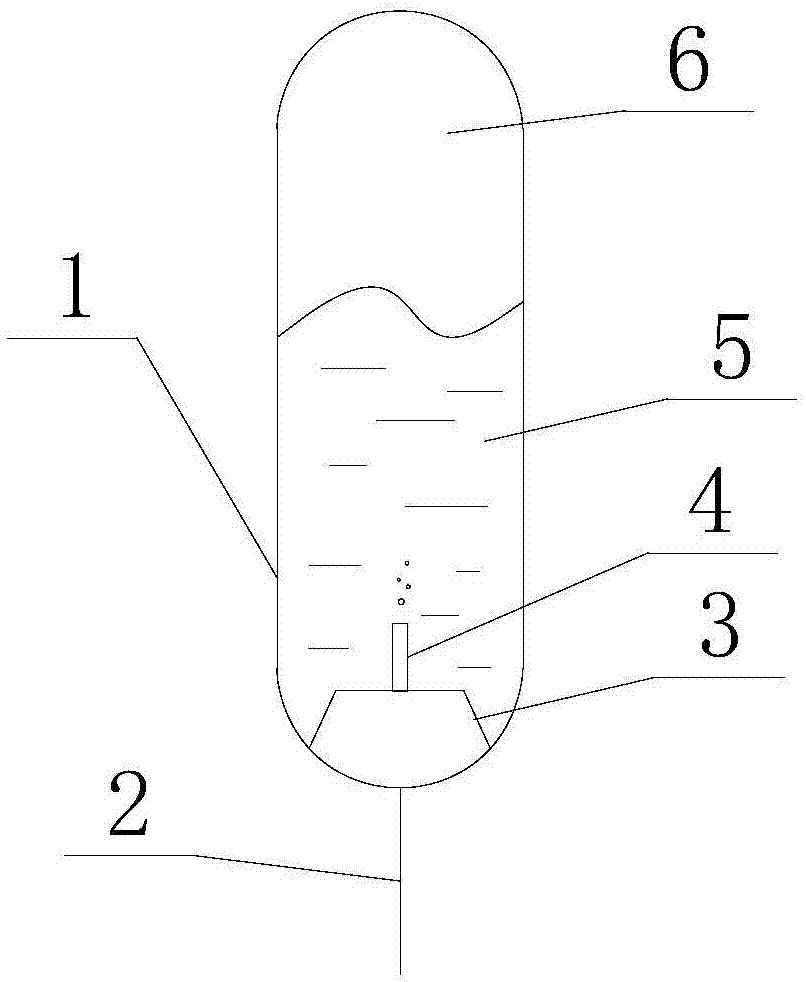

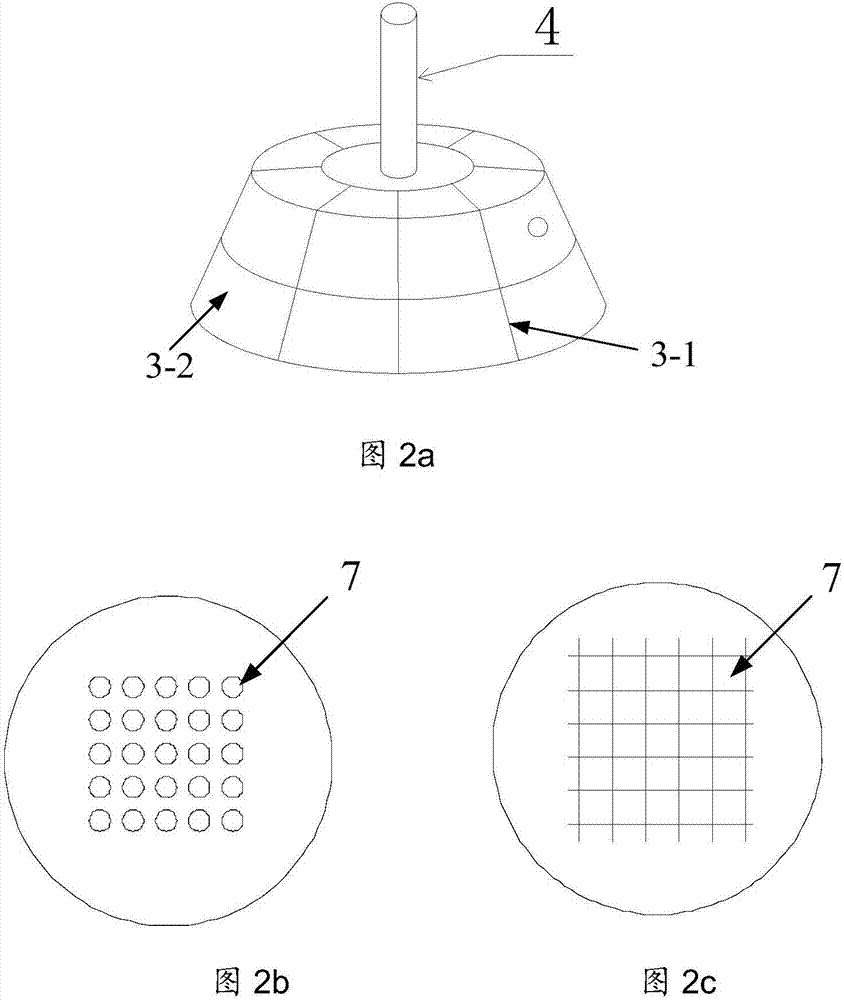

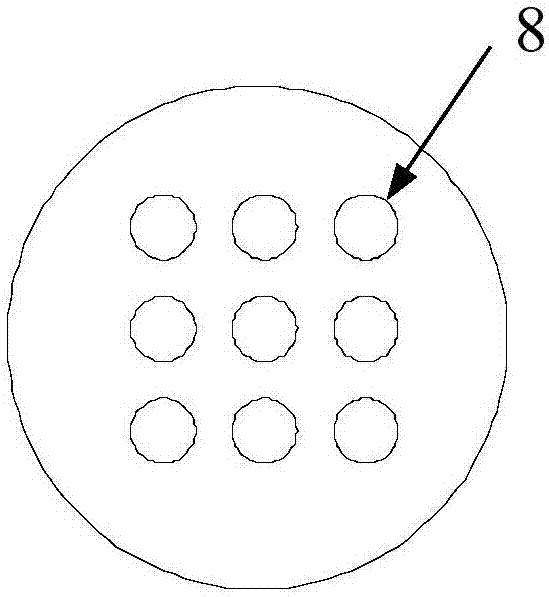

[0066] In this example, the spacecraft propellant selects unsymmetrical dimethylhydrazine and dinitrogen tetroxide, the storage tank 1 volume is 700L, the storage tank 1 height is 1300mm, and the starting basket device volume is 20L (outer frame 3 volume+exhaust pipe 4 Volume), the height of the exhaust pipe 4 is 150mm. Because parameters such as surface tension coefficient and density of unsymmetrical dimethyl hydrazine and dinitrogen tetroxide are different, the apertures of the first through holes 7 in the starter basket devices in the two kinds of propellant storage tanks are different, and the apertures of the second through holes 8 are also different. different.

[0067] In this example, during the first ignition of the main engine of the spacecraft, the axial overload of the spacecraft is 0.1g. Under this overload, the propellant at the top of the tank can theoretically move from the top of the tank to the bottom of the tank in 1.63s. , the propellant storage flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com