Rotary self-cleaning type fluted disc switching valve

A switching valve, self-cleaning technology, used in sliding valves, valve details, valve devices, etc., can solve the problems of large leakage of exhaust gas and difficult sealing of wind direction switching valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

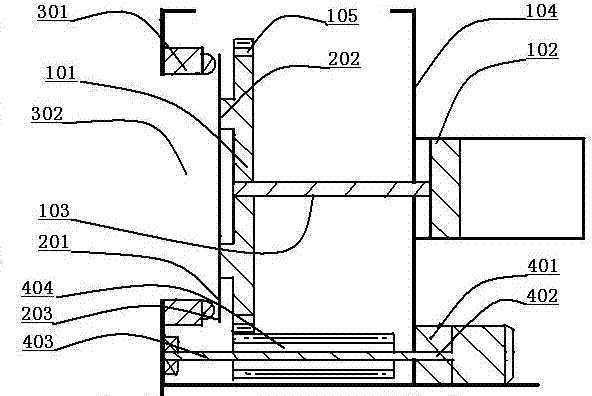

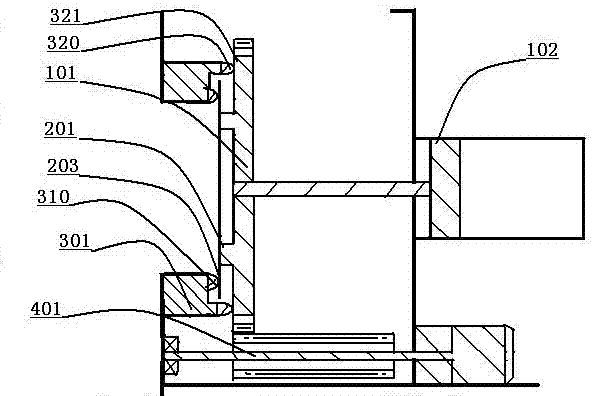

[0022] Such as figure 1 As shown, the rotary self-cleaning toothed plate switching valve includes a toothed plate 101 , a valve plate 201 , a valve seat 301 and a rotating device 401 . The toothed disc 101 is fixedly installed concentrically with the pull rod 103 of the cylinder 102 , and the cylinder 102 is fixed outside the gas distribution box 104 ; the outer wall of the toothed disc 101 is provided with a ring gear 105 . The valve plate 201 is fixedly installed on the inner wall surface 202 of the gear plate 101 . The valve seat 301 is installed on the vent 302 of the gas distribution box 104 , and the valve seat 301 is eccentrically installed with the pull rod 103 of the cylinder 102 . A gear 404 is installed on the transmission shaft 403 of the reduction motor 402 of the rotating device 401 , and the gear 404 is installed in contact with the ring gear 105 of the toothed disc 101 . Such as figure 2 As shown, the sealing wall surface 203 of the valve plate 201 contacts...

no. 2 example

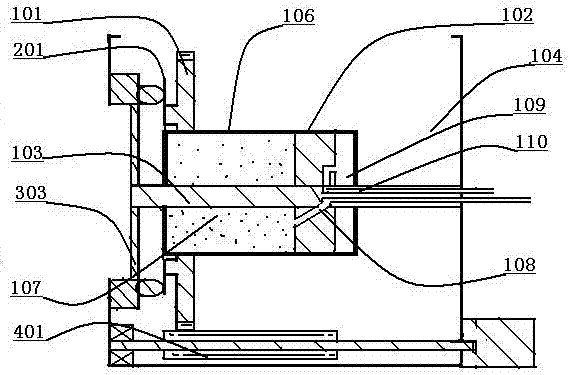

[0025] Such as image 3 As shown, the cylinder 102 is installed inside the gas distribution box 104, and one end of the pull rod 103 of the cylinder 102 is fixed on the inner wall of the gas distribution box 104, and the other end of the pull rod 103 is fixed on the valve seat 301 ring support 303. The toothed plate 101 and the valve plate 201 are fixed on the outer cylinder body 106 of the cylinder 102, the air pipe 108 of the upper cylinder chamber 107 of the cylinder 102 is installed in the inside of the pull rod 103, and the air pipe 110 of the lower cylinder chamber 109 of the cylinder 102 is installed on the inside of the pull rod 103. internal. Such as Figure 4 As shown, the ring disc 101, the valve plate 201 and the valve seat 301 are contacted and sealed to form an annular air-filled chamber 130, and an intake pipe 120 is installed between the annular air-filled chamber 130 and the lower cylinder chamber 109 of the cylinder 102, and the lower cylinder chamber 109 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com