Rotary automatic cleaning type switching valve of thermal storage combustion device

An automatic cleaning, regenerative combustion technology, applied in valve devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of large leakage of exhaust gas and difficult sealing of wind direction switching valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

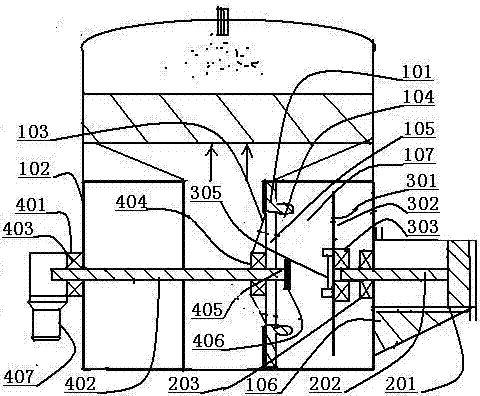

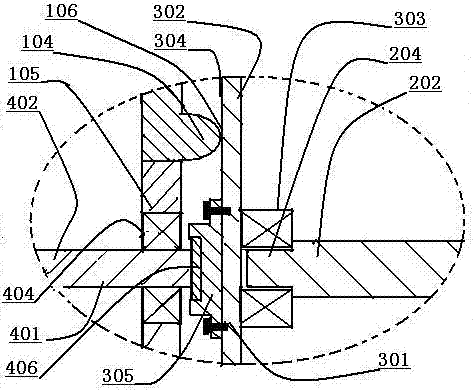

[0027] Such as figure 1 As shown, the rotary automatic cleaning switching valve of the regenerative combustion device includes: a valve seat 101 , a cylinder 201 , a rotary valve plate 301 and a rotary device 401 . The valve seat 101 is installed on the air duct opening 103 of the gas distribution box 102, and the side of the valve seat 101 is provided with an annular sealing port 104, and an annular bracket 105 is installed in the annular sealing port 104. Cylinder 201 is installed on the outer wall support 106 of gas distribution box 102, and the push-pull rod 202 of cylinder 201 stretches in the air channel 107 of gas distribution box 102, and this push-pull rod 202 is installed in the linear bearing seat 203 of air channel 107 wall surfaces. A self-aligning bearing seat 303 is installed on the lower wall of the valve plate 302 of the rotating valve plate 301 , and the connecting shaft head 204 of the push-pull rod 202 is installed in the self-aligning bearing seat 303 . A...

no. 2 example

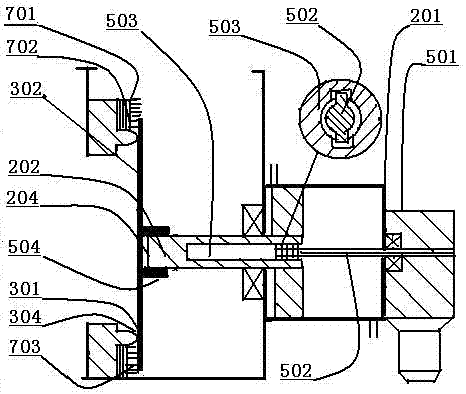

[0030] Such as image 3 As shown, the rotating device and the cylinder are fixedly installed, the cylinder 201 and the cylinder rotating device 501 are fixedly installed, and the transmission rod 502 of the cylinder rotating device 501 is installed in the connecting sleeve 503 inside the push-pull rod 202 . The connecting shaft head 204 of the push-pull rod 202 is fixedly installed in the fixed sleeve 504 of the rotary valve plate 301 . The transmission rod 502 of the cylinder rotating device 501 rotates, driving the push-pull rod 202 and the rotary valve plate 301 to rotate.

[0031] So far, the second embodiment of the present invention, the rotary automatic cleaning switching valve of the regenerative combustion device, has been introduced.

no. 3 example

[0033] In order to improve the cleanliness of the rotary valve plate 301, as Figure 4 As shown, a scraper cleaning device 602 is installed on the support arm surface 601 of the annular support 105, and the elastic scraper 603 of the scraper cleaning device 602 is fixedly installed obliquely with the support arm surface 601 through the pressure plate 604, and the top end of the elastic scraper 603 extends Out of the ring sealing port 104. The elastic scraper 104 deforms after being squeezed by the valve plate 302 , and sticks to the sealing wall 304 of the valve plate 302 . The rotary valve plate 301 rotates, and the elastic scraper 104 removes the dirt on the sealing wall 304 of the valve plate 302 . Such as image 3 As shown, a cleaning device 601 is fixedly installed on the outside or inside wall of the valve seat 101 annular sealing port 104, and a cleaning grinding head 603 is installed in the elastic seat 602 of the cleaning device 601; the rotating valve plate 301 rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com