A device for cleaning the inner side of the extrusion ring of a mixer

A technology for cleaning devices and extruding rings, which is applied in mixers, mixers with rotating mixing devices, transportation and packaging, etc., can solve problems such as uneven mixing and mixing machine spraying slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

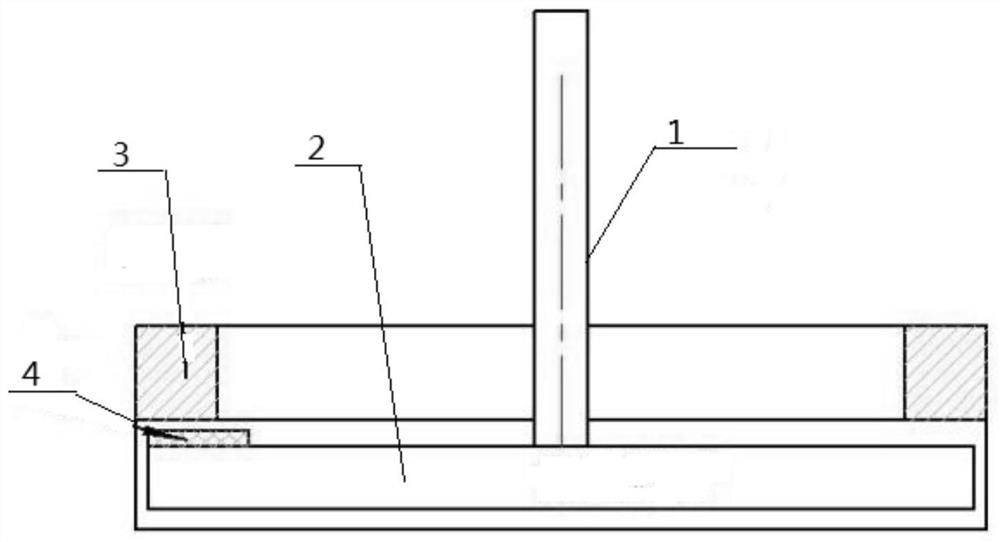

[0018] Example 1 as figure 1 As shown, a device for cleaning the accumulated material inside the extrusion ring of a mixer includes a mixer rotor, a scraper 4 and an extrusion ring 3. The mixer rotor is an integrated structure formed by vertically connecting the rotating shaft 1 along the center of the turntable 2. The end face of the turntable 2 and the end face of the extrusion ring 3 are parallel and coaxially opposed to each other, and the cavity formed between the two is a blanking gap. The scraper 4 is fixed on the top edge of the turntable 2 and is located at Below the squeeze ring 3 , the scraper 4 is fastened on the turntable 2 of the mixer rotor by screws, and the scraper 4 is arranged facing the squeeze ring 3 with a predetermined gap between the squeeze ring 3 .

[0019] The main working principle is as follows: the cleaning device is mainly composed of a chrome-plated stainless steel plate with a size of 3cm*10cm*3mm, such as figure 1 As shown, the scraper 4 is f...

Embodiment 2

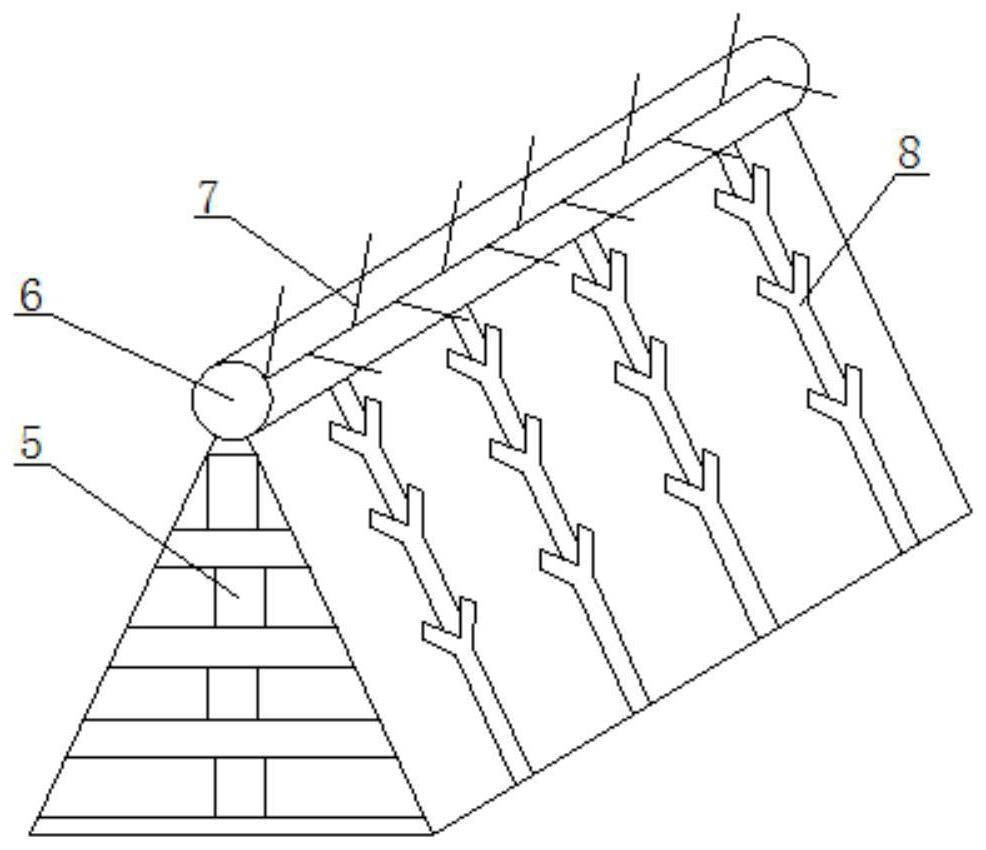

[0021] On the basis of Example 1, different from Example 1, such as figure 2 As shown, the scraper 4 is arranged as a horizontal triangular prism structure, and its side wall is set close to the surface of the turntable 2. The scraper 4 is fixedly installed on the outer edge of the turntable 2, and the extension direction of the scraper 3 extends along the radius of the turntable 2. The direction is set, and the special structure of the scraper 4 makes the walls on both sides form a certain slope, which has the function of diverting flow and preventing materials from sticking, and forms a good diversion effect during the rotation process.

[0022] The inside of the scraper 4 is provided with a "convex"-shaped support frame 5 from top to bottom. The support frame 5 is arranged from top to bottom along the taper, and the support stability is strong, which prevents the scraper 4 from being deformed by the impact force, enhances the cutting force of the scraper 4, and prolongs th...

Embodiment 3

[0026] On the basis of Embodiment 1, different from Embodiment 1, the turntable 2 is arranged downward in a certain arc from the center position to form a bamboo hat structure. The slope surface has flow conductivity, so that the material can be quickly and evenly dispersed from the blanking gap under the action of centripetal force.

[0027] The upper surface of the turntable 2 is concentrically arranged with diversion grooves arranged in a circular shape. The diversion grooves are configured as cylindrical structures protruding from the upper surface of the turntable. The height of the diversion grooves gradually decreases from the center to the outside. The setting of the diversion groove enables the material to be evenly dispersed along the surface of the turntable 2 under the action of the rotating centripetal force, which improves the uniformity of material dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com