Integrated monitoring system for power transformer operation

A technology for comprehensive monitoring of power transformers, applied in the direction of instruments, measuring devices, etc., can solve the problems of low monitoring accuracy and lack of simultaneous monitoring of multiple operating data of transformers, and achieve the effects of improving maintenance management efficiency, low cost, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

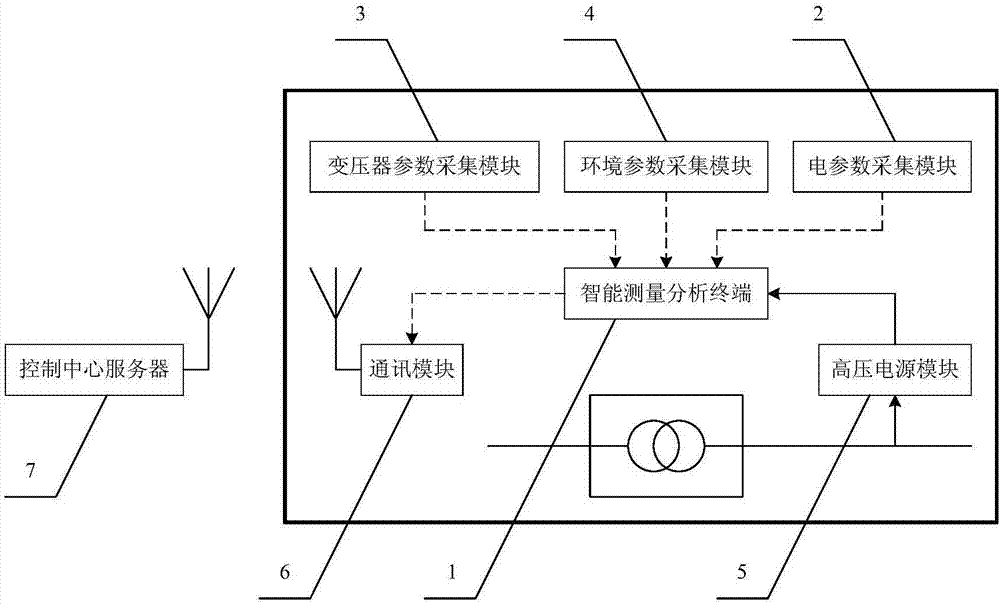

[0014] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, a comprehensive monitoring system for power transformer operation described in this embodiment, which includes an intelligent measurement and analysis terminal 1, an electrical parameter acquisition module 2, a transformer parameter acquisition module 3, an environmental parameter acquisition module 4 and a power supply module 5 ,

[0015] The power module 5 is used to take power from the low-voltage side of the transformer to supply power to the intelligent measurement and analysis terminal 1;

[0016] The electrical parameter acquisition module 2 is used for real-time acquisition of three-phase current and three-phase voltage data during the operation of the transformer, and sends the collected data to the intelligent measurement and analysis terminal 1;

[0017] The transformer parameter acquisition module 3 is used to collect the oil temperature, oil pressure and oil level dat...

specific Embodiment approach 2

[0023] Specific embodiment two: This embodiment is a further description of a power transformer operation comprehensive monitoring system described in specific embodiment one. In this embodiment, it also includes a communication module 6 and a control center server 7,

[0024] The intelligent measurement and analysis terminal 1 sends data to the control center server 7 through the communication module 6 .

[0025] In this embodiment, the intelligent measurement and analysis terminal 1 performs data storage, calculation, and analysis, and uploads the data to the control center server 7 through the communication module 6 .

[0026] The control center server 7 establishes a transformer parameter database and long-term historical operation records, analyzes its health status according to various operation data, and assists in formulating a maintenance plan for the transformer.

[0027] After the transformer fails or is scrapped, the control center server 7 analyzes the design defe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com