Dual-liquid-level controller

A liquid level controller, high liquid level technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve the problems of high cost, low reliability, complex structure and other problems of the controller, and reach the service life Long-term, high reliability and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in detail below with reference to specific embodiments.

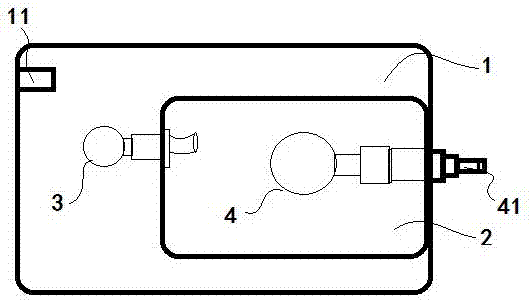

[0011] like figure 1 As shown, the dual liquid level controller described in this embodiment is composed of a liquid container 1 and a control container 2, and the control container 2 is inverted in the liquid container 1, and one side wall of the two is close together; An exhaust float valve 3 is arranged between the container 1 and the control container 2 , and the air inlet of the exhaust float valve 3 is connected with the side wall of the control container 3 and extends into the control container 2 . The inside of the control container 2 is provided with an adjustable high liquid level control float valve 4. The liquid inlet 41 of the float valve 4 is connected to the external liquid input pipeline through the side wall of the control container and the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com