Exhaust fan panel used for high-rise housing flue

An exhaust fan and panel technology, which is applied to the components of the pumping device for elastic fluids, non-variable-capacity pumps, pump components, etc., can solve the problems of the exhaust fan being difficult to seal, the backflow of smoke, and the low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

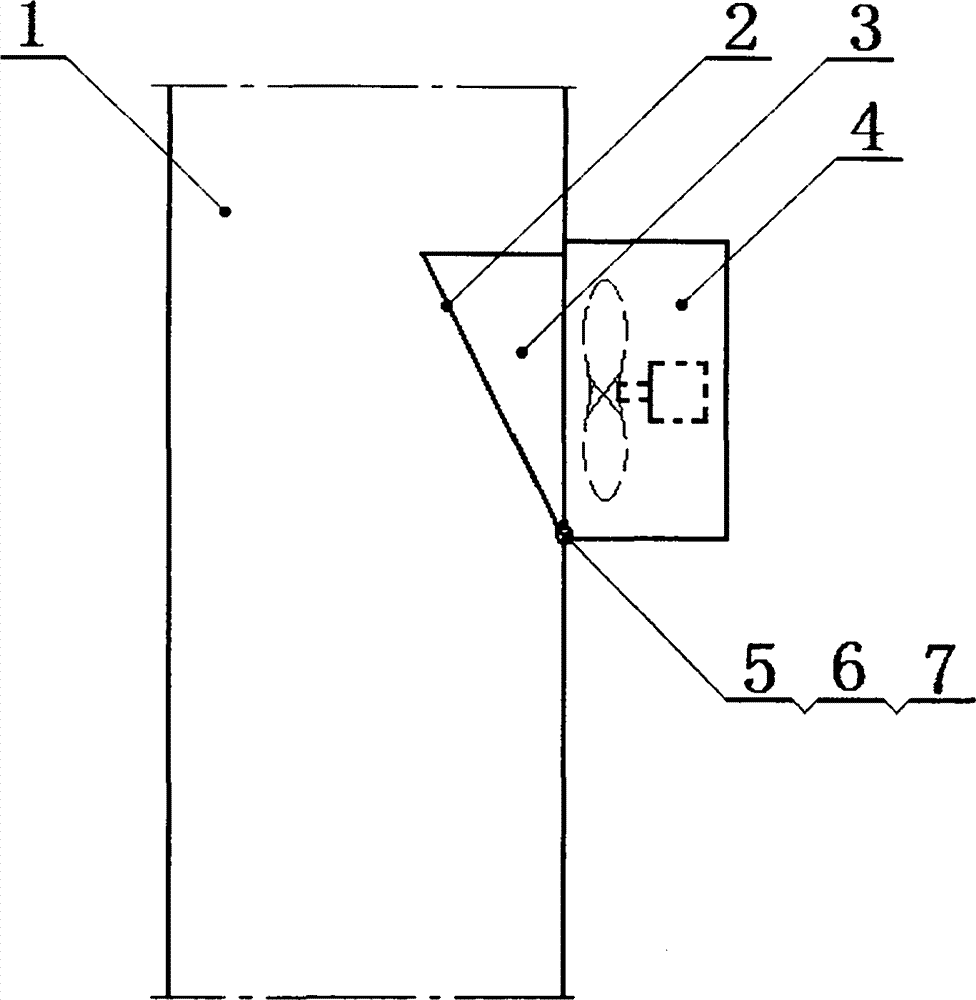

[0013] like figure 1 It is one of the schematic diagrams of the present invention, the panel (2) is rectangular and its two sides are connected with the triangular side panels (3), and the panel opens an upward opening when the exhaust fan is working.

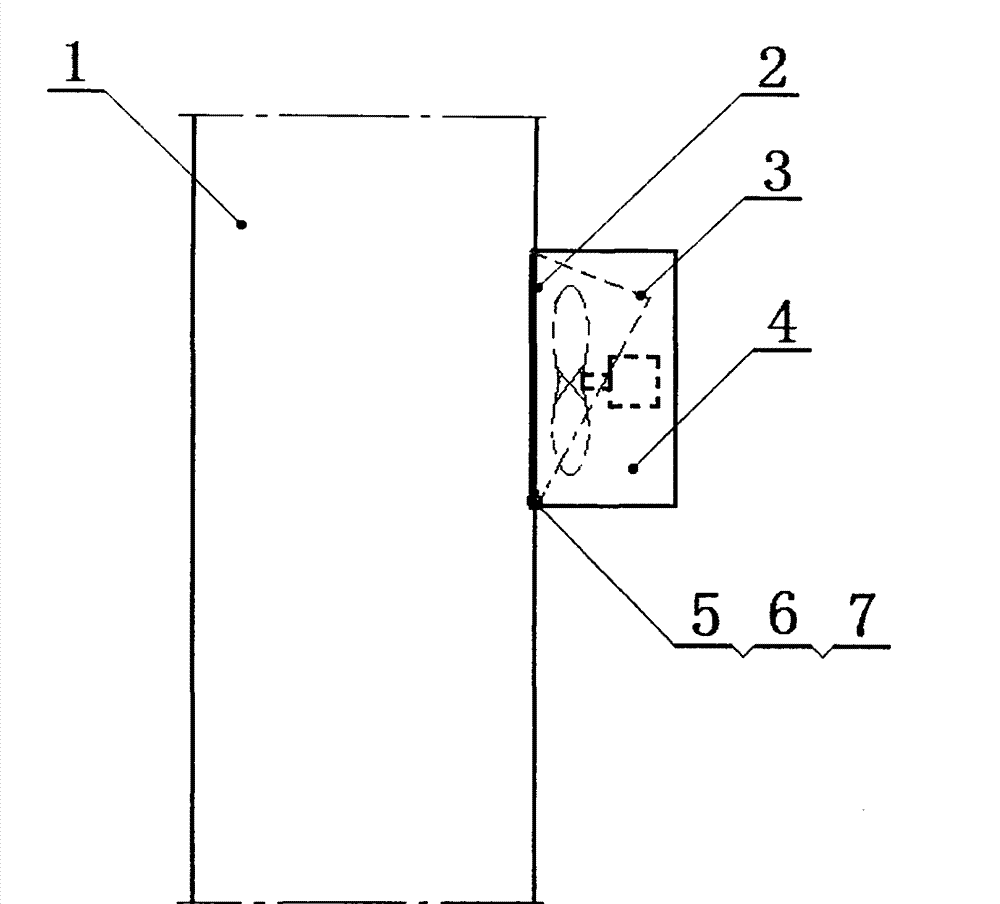

[0014] like figure 2 It is the second schematic diagram of the present invention. When the exhaust fan is not working, the elastic force of the stainless steel torsion spring (7) closes the air outlet of the panel (2) and the outer cover (4). At this time, the triangular side plate (3) All are also included in the outer cover (4), and the panel (2) coincides with the inner wall of the flue (1).

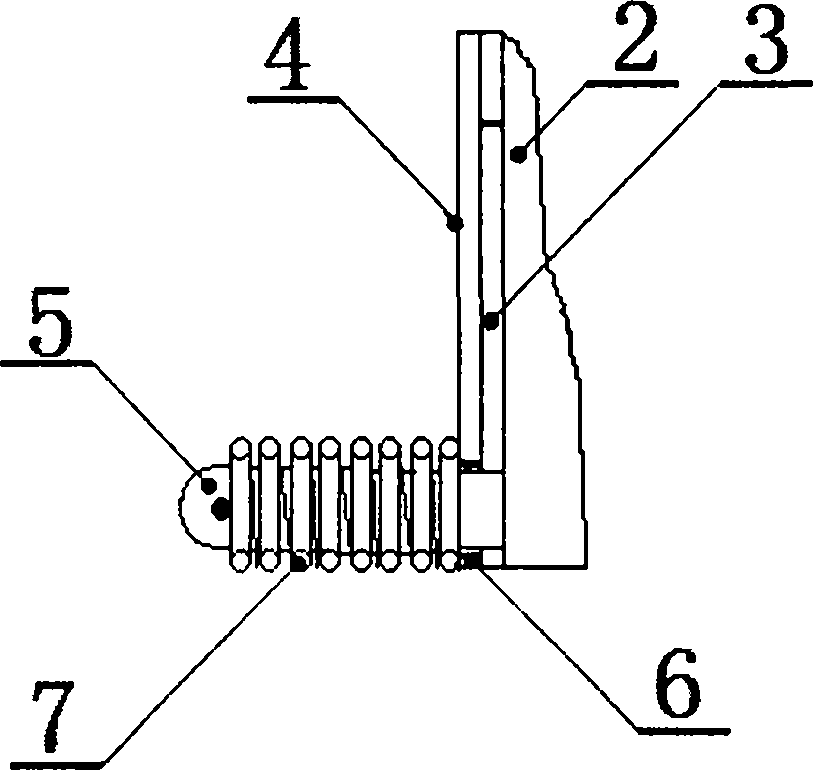

[0015] like image 3 Yes figure 2 Partially enlarged right view schematic diagram, under the action of the stainless steel torsion spring (7), the panel (2) and the air outlet of the outer cover (4) are closed.

[0016] The exhaust fan panel for the flue of a high-rise residence is mainly composed of a panel (2), a triangular sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com