Anti-current deepwater net cage system

A deep-water cage and cage technology, which is applied in fish farming, application, climate change adaptation, etc., can solve problems such as practical limitations, a large number of waste nets, and different cage configurations. Conducive to environmental protection and the effect of reducing volume loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

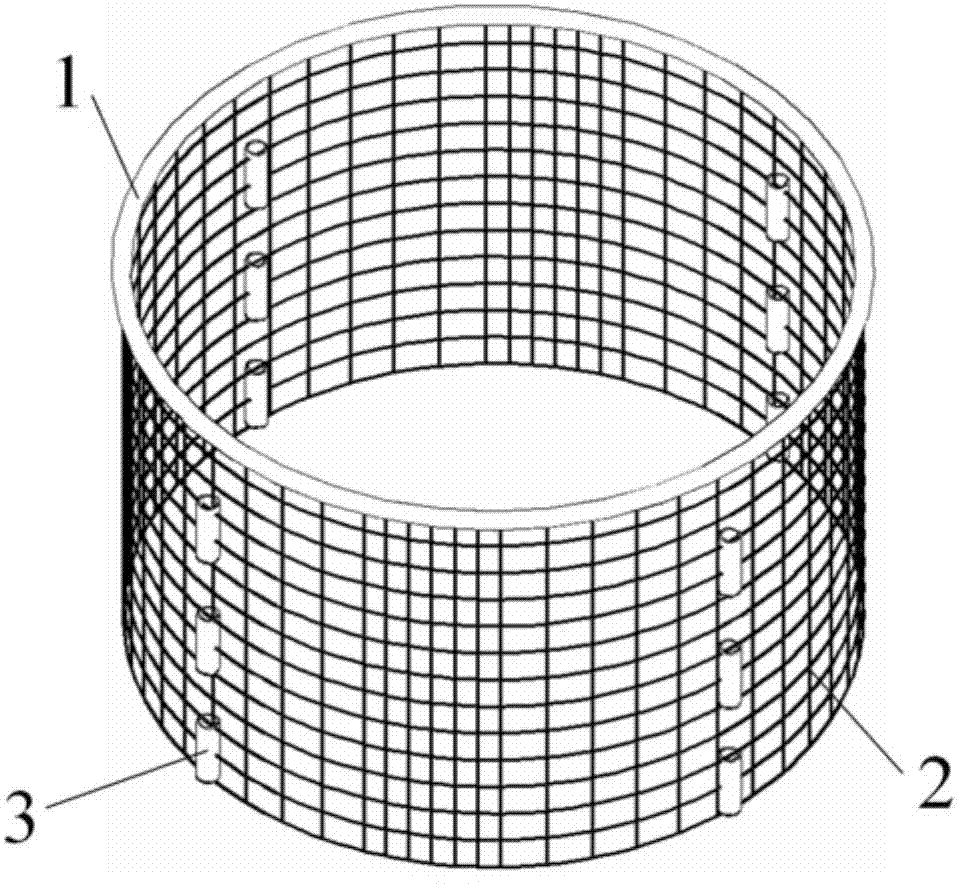

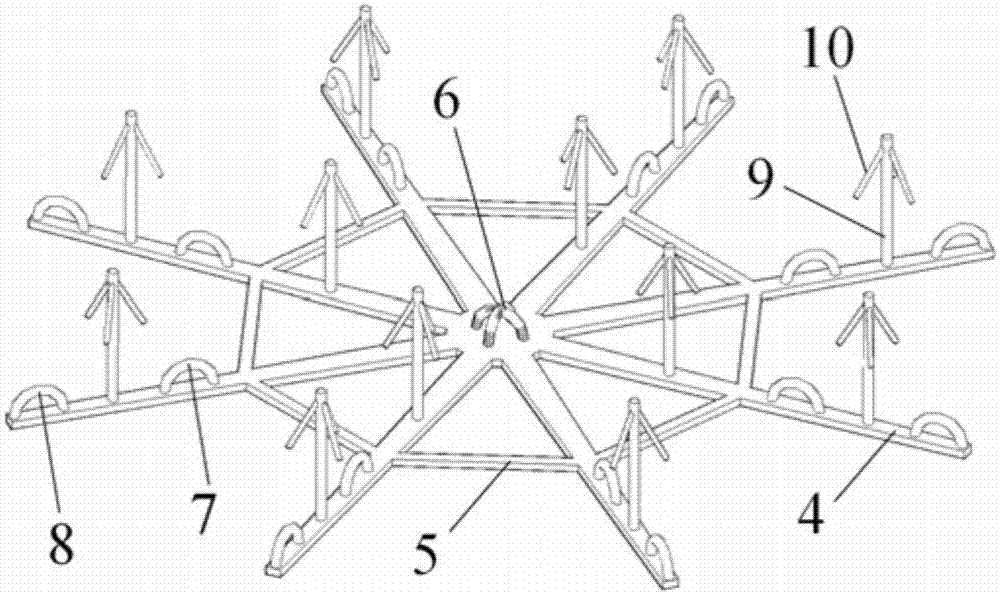

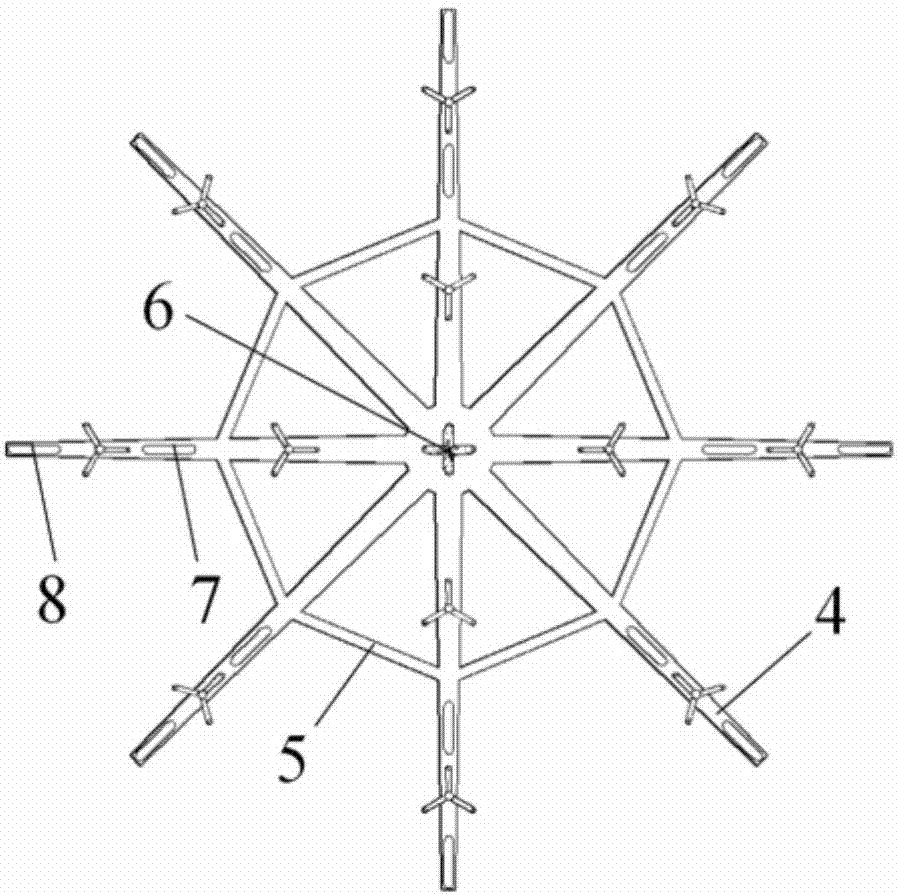

[0099] Embodiment 1: as Figure 6 , Figure 8 , Figure 9 As shown, the basic support 4 is welded by eight identical steel plates to form a "meter-shaped" axisymmetric structure, and each sleeve rod 9 on the basic support 4 is evenly and symmetrically inserted into the ring-shaped counterweight 11 . After cable 15 passes through each column sleeve pipe 3 on the net clothes 2, one end of cable 15 is moored on the net cage frame 1, and the other end is moored on the net cage mooring ring 7 of foundation support 4, and each cable 15 Bind a confinement ring 13 at the same position as Figure 6 shown.

[0100] The quantity of cables 15 on the net cage frame 1 is four, and is evenly distributed around the net cage frame. That is to say, the number of mooring points is four, and they are evenly distributed around the frame of the cage. This design can greatly reduce the stress concentration at the mooring points of the floating tube frame of the cage, and the wind and wave load b...

Embodiment 2

[0104] Embodiment 2: as Figure 10 As shown, after the cables 15 on the net cage pass through the sleeves 3 of each row on the net clothes 2, one end of the cables 15 is moored on the cage frame 1, and the other end is moored on the middle mooring ring 6 of the foundation support 4 Above, bind a confinement ring 13 at the same position of each cable 15, and the rest of the situation is the same as in Embodiment 1.

Embodiment 3

[0105] Embodiment 3: as Figure 15 As shown, the arc length of the anti-flow frame 16 is 270°, and the other conditions are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com