A bottle opener and a method for opening a bottle cap using the bottle opener

A bottle opener and bottle cap technology, applied in the field of bottle openers, can solve the problems of high force and increase the difficulty of screwing the bottle cap, and achieve the effect of labor-saving and convenient opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

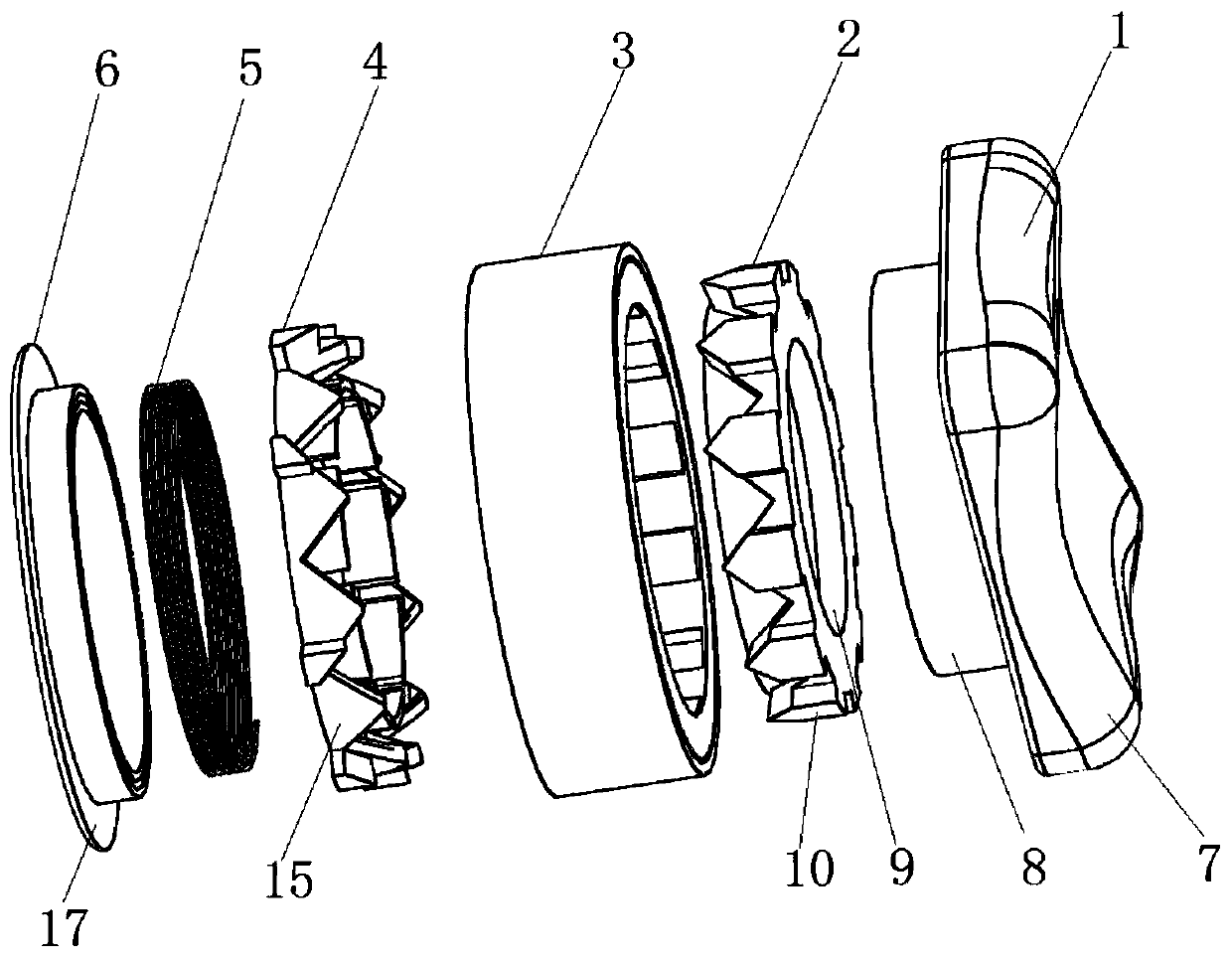

[0024] Embodiment 1 of the present invention: a bottle opener, including a pressing cover 1, an upper toothed ring 2, a retaining ring 3, a lower toothed ring 4, a large return spring 5 and a bottom ring 6, and the upper toothed ring 2 is arranged on Inside the retaining ring 3 , the lower toothed ring 4 is sheathed in the retaining ring 3 , the retaining ring 3 is arranged between the pressing cover 1 and the bottom ring 6 , and the large return spring 5 is arranged in the bottom ring 6 .

Embodiment 2

[0025] Embodiment 2 of the present invention: a bottle opener, including a pressing cover 1, an upper toothed ring 2, a retaining ring 3, a lower toothed ring 4, a large return spring 5 and a bottom ring 6, and the upper toothed ring 2 is arranged on Inside the retaining ring 3 , the lower toothed ring 4 is sheathed in the retaining ring 3 , the retaining ring 3 is arranged between the pressing cover 1 and the bottom ring 6 , and the large return spring 5 is arranged in the bottom ring 6 .

[0026] Further, the pressing cover 1 includes an upper pressing part 7 and an engaging part 8 connected with the upper pressing part 7 , and the engaging part 8 is connected with the retaining ring 3 .

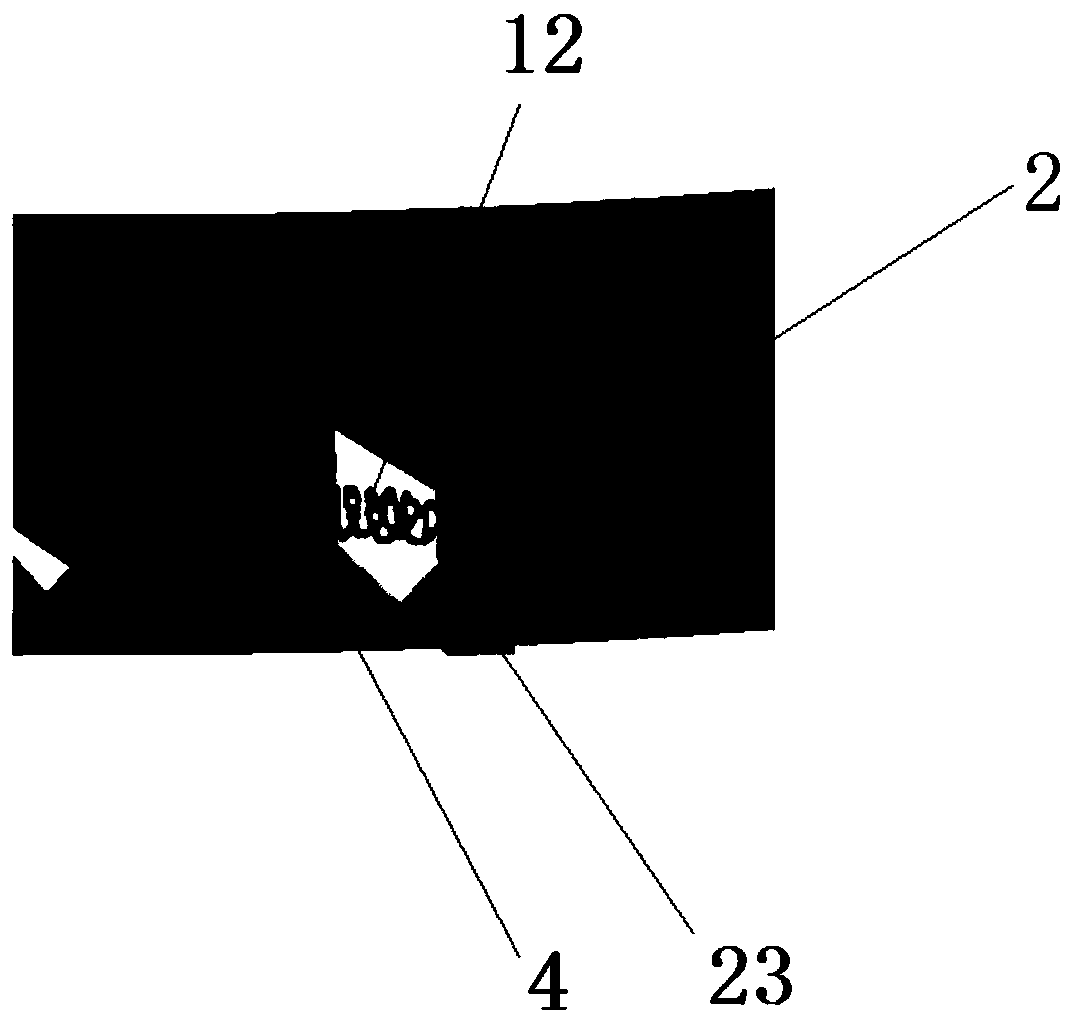

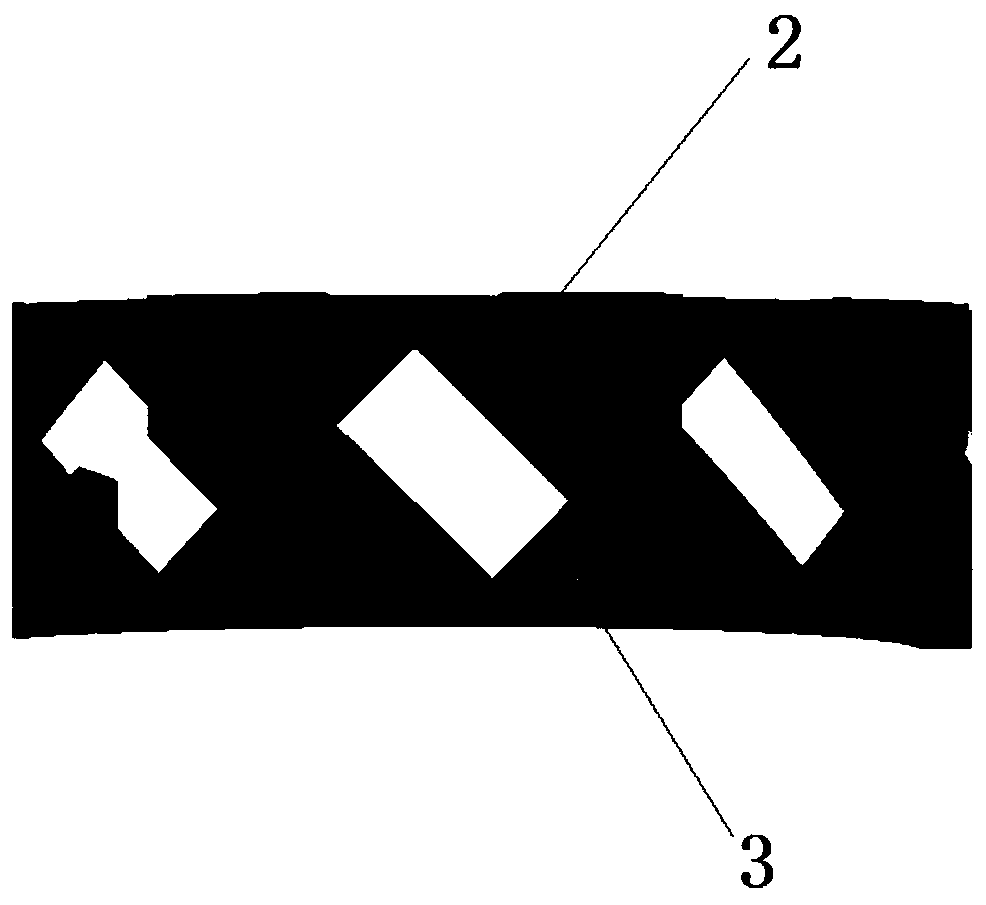

[0027] Further, the upper toothed ring 2 includes an inner ring structure 9 and an outer ring tooth portion 10 , and the outer ring tooth portion 10 is integrally formed with the inner ring structure 9 or is sheathed on the outer wall of the inner ring structure 9 .

[0028] Further, the i...

Embodiment 3

[0032] Embodiment 3 of the present invention: a bottle opener, including a pressing cover 1, an upper toothed ring 2, a retaining ring 3, a lower toothed ring 4, a large return spring 5 and a bottom ring 6, and the upper toothed ring 2 is arranged on Inside the retaining ring 3 , the lower toothed ring 4 is sheathed in the retaining ring 3 , the retaining ring 3 is arranged between the pressing cover 1 and the bottom ring 6 , and the large return spring 5 is arranged in the bottom ring 6 .

[0033] Further, the pressing cover 1 includes an upper pressing part 7 and an engaging part 8 connected with the upper pressing part 7 , and the engaging part 8 is connected with the retaining ring 3 .

[0034] Further, the upper toothed ring 2 includes an inner ring structure 9 and an outer ring tooth portion 10 , and the outer ring tooth portion 10 is integrally formed with the inner ring structure 9 or is sheathed on the outer wall of the inner ring structure 9 .

[0035] Further, the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap