Method for operation switching of reeding machine, and dropping bar

A technology of reeding machine and operation, which is applied in the field of reeding machine operation switching method and its menopause strip, can solve the problems of affecting the efficiency of reeding machine, time-consuming and labor-intensive operation, and long time consumption, so as to shorten the switching time of a single operation and improve The effect of finishing speed and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Plain weave varieties, the total number of roots is 8016;

[0033] A kind of reeding machine work switching method described in the present invention, comprises the following steps:

[0034] (1) Push the reed creel trolley on which the weaving shaft is to be threaded to the joint of the reed machine, and connect the creel and the reed machine;

[0035] (2) the steel reed of the technical requirements of the variety to be worn is installed on the steel reed running car;

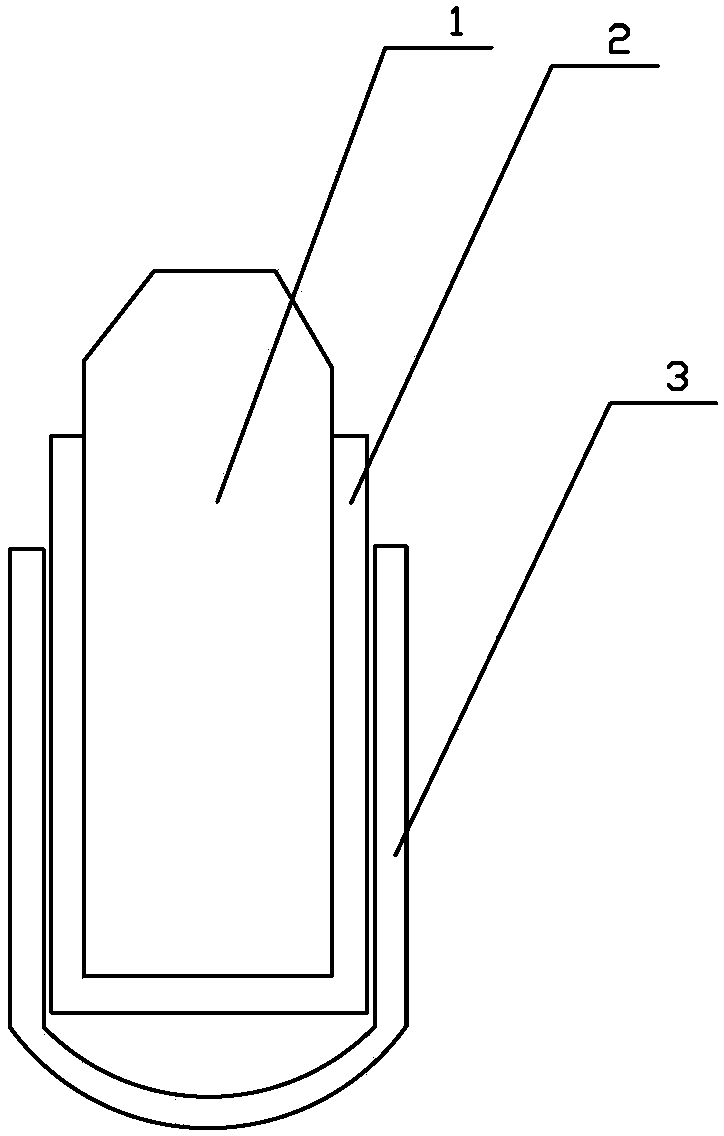

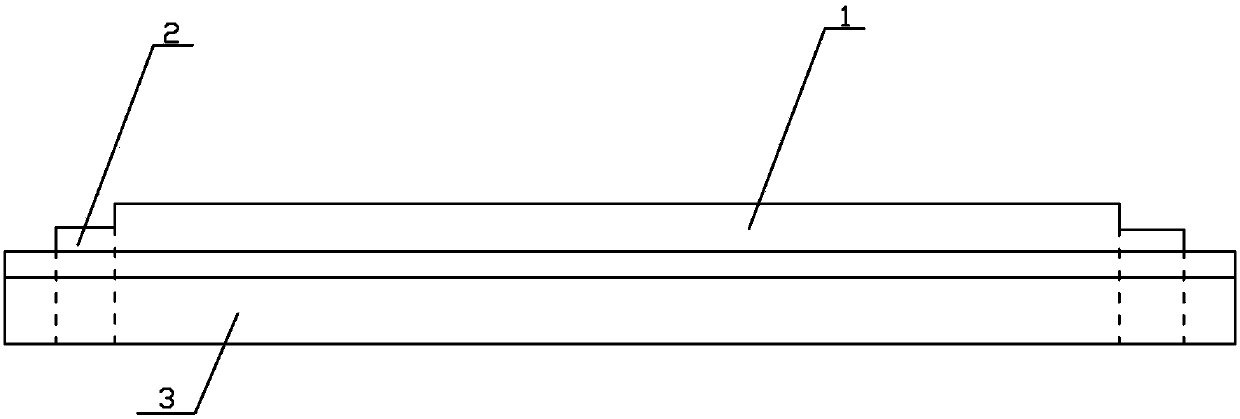

[0036] (3) The new warp strips are installed in the warp strip slots, the warp strips are fixed with setscrews, the front end is connected with the reeding machine, and the first menopause strip support frame is installed at a distance of 20cm from the reeding machine;

[0037] (4) Pass the skeined fishing line through the yarn splitter of the reeding machine, and fix the fishing line at the tension shrapnel of the creel;

[0038] (5) Install the heald frame according to the technical requirements of ...

Embodiment 2

[0050] Jacquard varieties, the total number of roots is 13295;

[0051] The menopause strip used in the present invention is the same as that used in Example 1.

[0052] A kind of reeding machine work switching method described in the present invention, comprises the following steps:

[0053] (1) Push the reed creel trolley on which the weaving shaft is to be threaded to the joint of the reed machine, and connect the creel and the reed machine;

[0054] (2) the steel reed of the technical requirements of the variety to be worn is installed on the steel reed running car;

[0055] (3) Install the new warp strips at the menopause strip slot, fix the warp strips with set screws, connect the front end with the reeding machine, and install the first menopause strip support frame at a distance of 17cm from the reeding machine;

[0056] (4) Pass the skeined fishing line through the yarn splitter of the reeding machine, and fix the fishing line at the tension shrapnel of the creel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com