Integrated solenoid valve casing

An integrated, electromagnetic valve technology, applied in the field of electromagnetic valves, can solve the problems of lower yield rate and many solenoid valve design processes, and achieve the effects of improving yield rate, avoiding assembly, and reducing installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

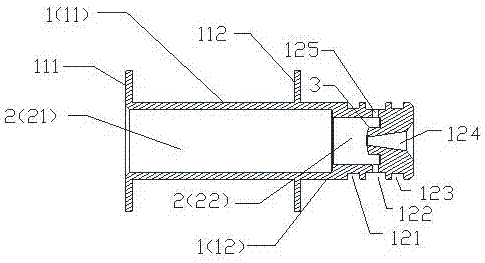

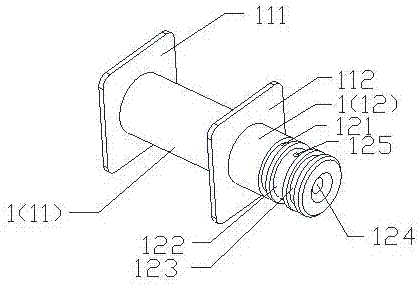

[0020] A one-piece solenoid valve bushing, such as figure 1 and figure 2 As shown, the one-piece sleeve main body 1 is injection molded at one time, and its upper and outer sides are provided with a working section 11 and a working section 12, while the inside of the sleeve main body 1 is provided with a groove section 2, and the groove section 2 includes a rear end with a larger diameter and a fixed The groove section 21 and the closed groove section 22 with a smaller diameter at the front end, the working section 11 includes a first flange 111 at the rear end and a second flange 112 at the front end, and the working section 12 includes a first sealing groove 121 provided at the rear end, a middle part The air hole groove 122 and the second sealing groove 123 at the front end.

[0021] In the above, the first air hole 124 is provided inside the working section 12, and the first air hole 124 communicates with the groove section 2, and a number of second air holes 125 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com