Mask plate, oled display substrate and manufacturing method thereof, display device

A technology for a display substrate and a manufacturing method, which can be applied to static indicators, patterned surface photoengraving processes, semiconductor/solid-state device manufacturing, etc., can solve problems such as uneven display brightness, improve display quality, and improve display brightness unevenness. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

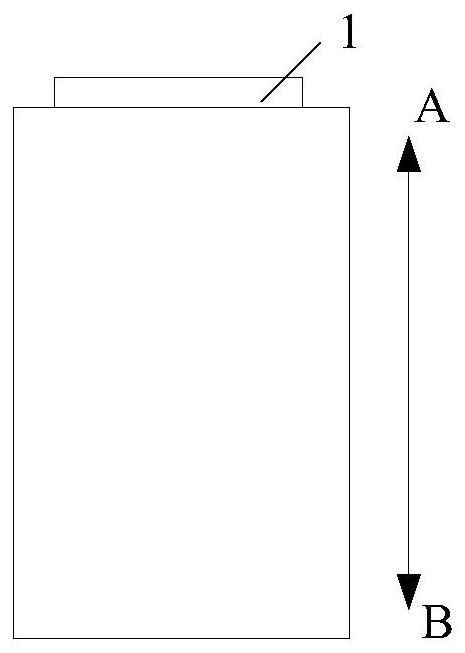

[0038] Such as figure 1 As shown, in the existing OLED display device, IC (driving circuit) 1 inputs Vss signal to the cathode, IC1 inputs Vdd signal to the anode, and the voltage difference between the Vdd signal and the Vss signal is the driving voltage ΔV, which is driven by the driving voltage ΔV The luminescent material emits light.

[0039] Since there is a certain impedance in the data line of the OLED display device, such as figure 1 As shown, in the direction from A to B, there is a certain voltage drop between the Vdd signal at the far end of the IC and the Vdd signal at the near end of the IC, resulting in a difference between the driving voltage ΔV at the far end of the IC and the driving voltage ΔV at the near end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com