Pad printing machine

A pad printing machine and rack technology, applied in printing machines, rotary printing machines, printing and other directions, can solve the problems of the next process, affecting production efficiency, ink leakage from the ink cup, etc., to avoid ink overflow and improve printing efficiency. and printing quality, the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

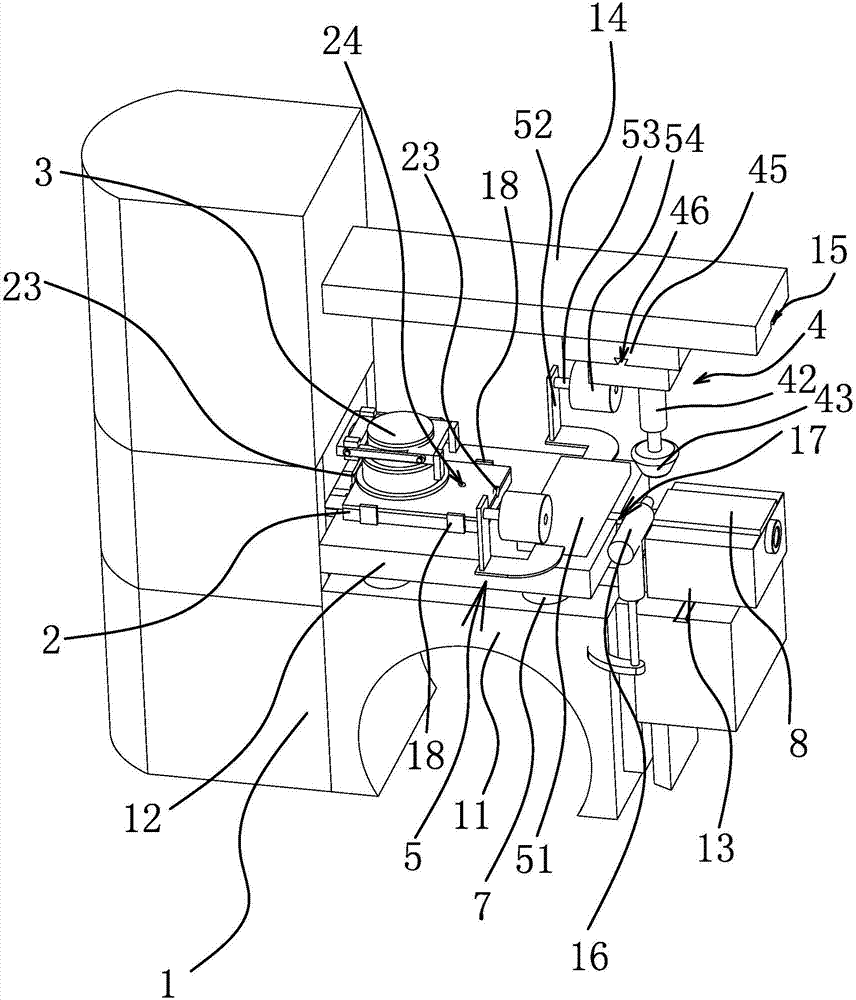

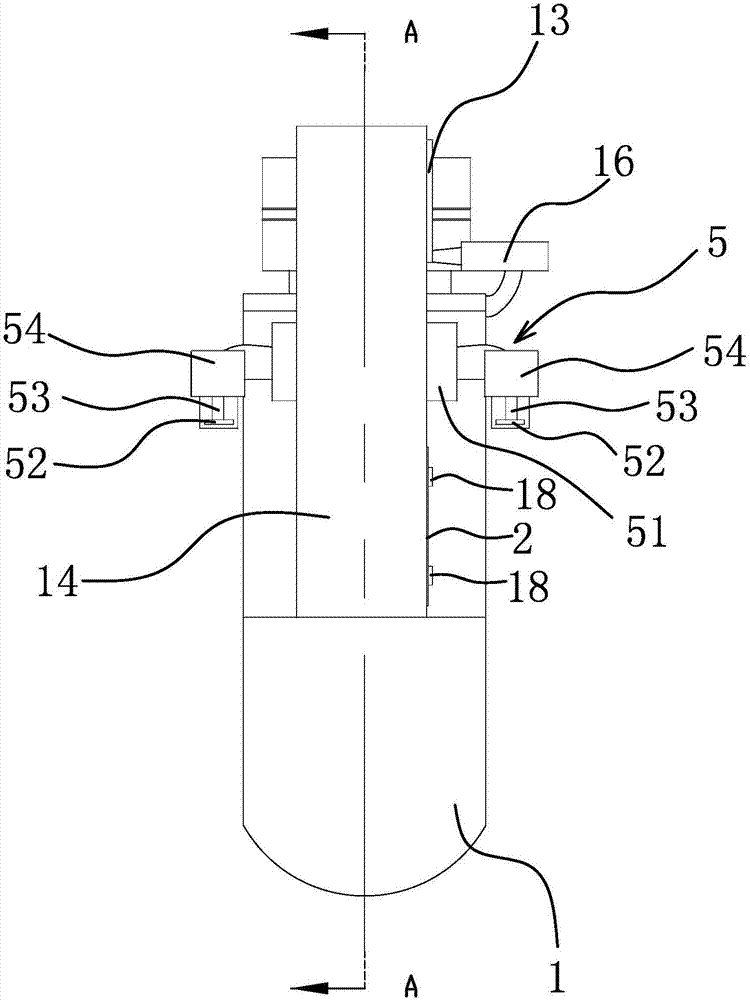

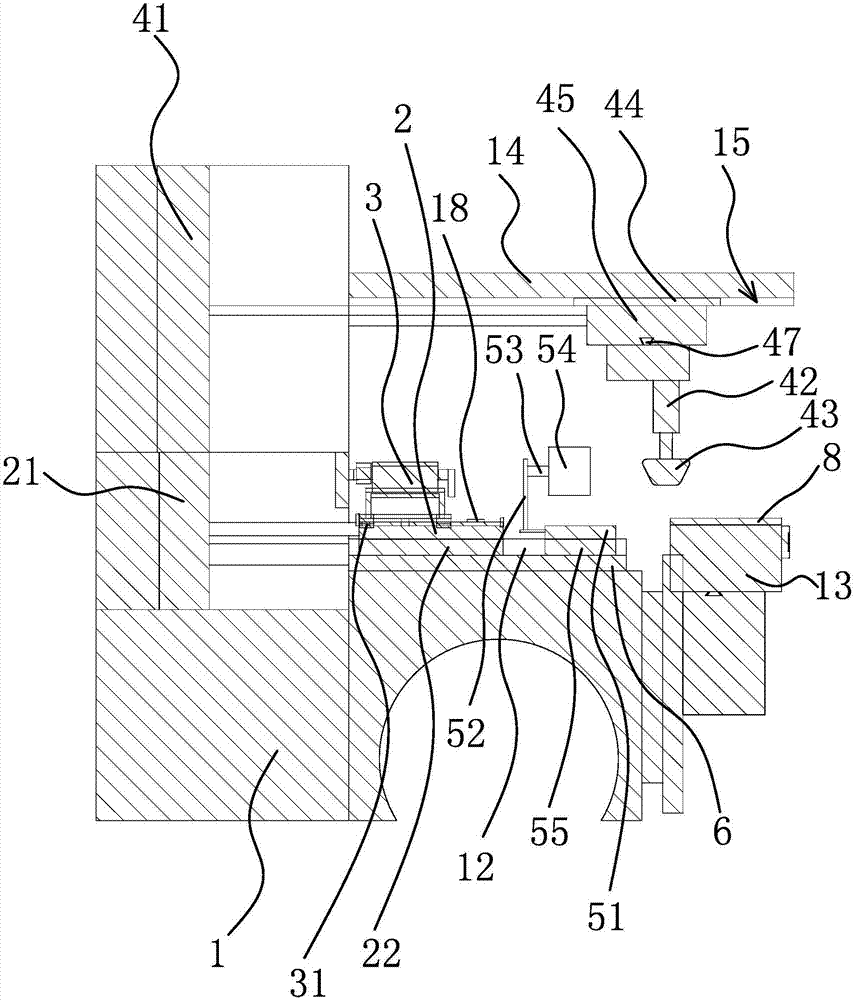

[0038] Such as figure 1 As shown, the pad printing machine includes a frame 1, a workbench 11 is provided in the frame 1, a base plate 12 and a work plate 13 for placing the workpiece 8 are provided on the workbench 11, and a supporting plate 2 is provided on the base plate 12. One end of the supporting plate 2 is connected with a cylinder one 21 .

[0039] Specifically, if Figure 1-4As shown, the supporting plate 2 is provided with an ink cup 3 fixedly connected with the frame 1, the supporting plate 2 protrudes to form a guide bar 22, and the bottom plate 12 is provided with a chute 17, the guide bar 22 can be embedded in the chute 17 and guide The bar 22 slides along the chute 17, and the supporting plate 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com