Lifter with double-layer lifting function and working method thereof

A lift and function technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of long hydraulic rod length, insufficient lift function, and inability to adjust the distance between different models of cars, so as to achieve simple and convenient use. , Troubleshooting safe and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

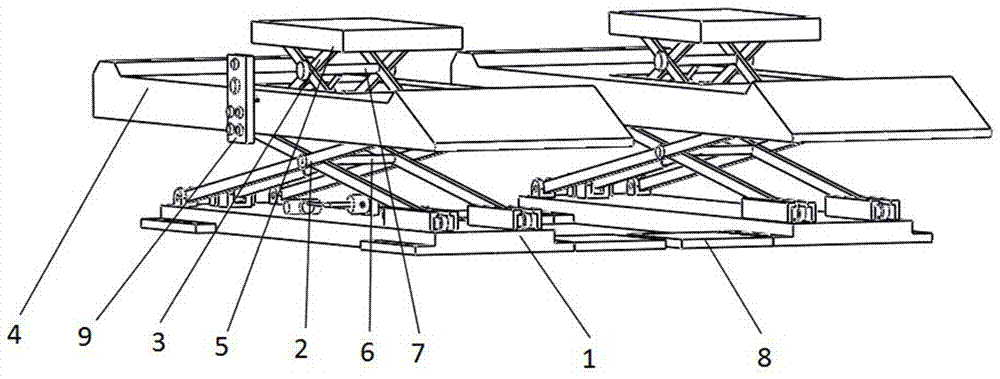

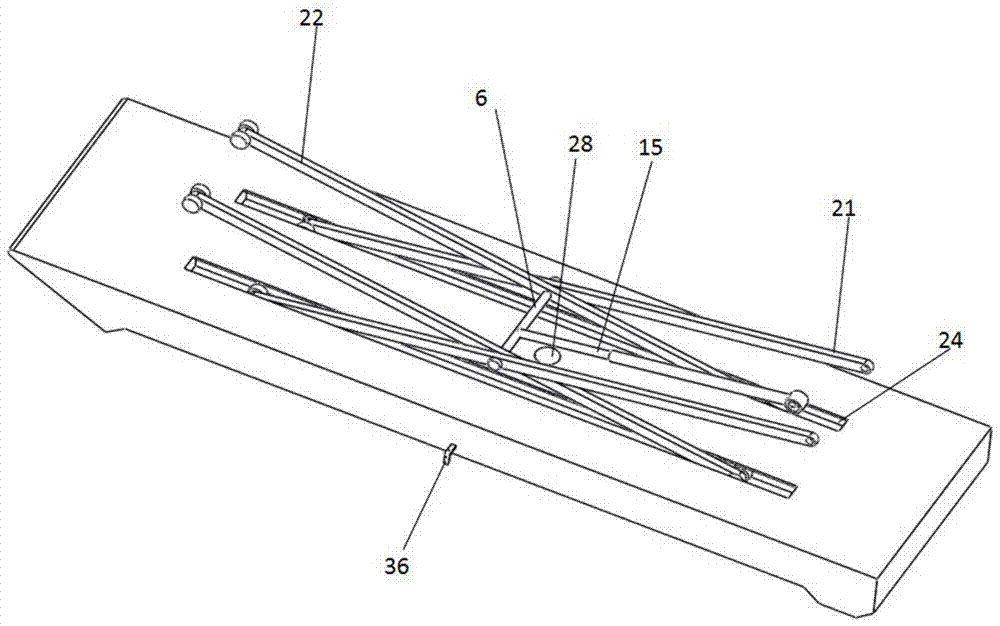

[0030] The invention discloses a lift with a double-layer lifting function, such as Figure 1 to Figure 6 As shown, it includes a hydraulic system, a set of bases 1, a set of first scissor support arms 2, a set of second scissor support arms 3, a set of lifting tables 4, a set of pallets 5, and a set of first beams 6 , a set of second beams 7, a set of adjustable connecting plates 8, and a control module 9, wherein the lower part of the first scissor support arm 2 is connected to the base 1, the upper part is connected to the lifting platform 4, and the middle is connected to the first beam 6; The lower part of the second scissor support arm 3 is connected with the lifting platform 4 , the upper part is connected with the tray 5 , and the middle part is connected with the second beam 7 ; the adjustable connecting plate 8 is connected with the base 1 .

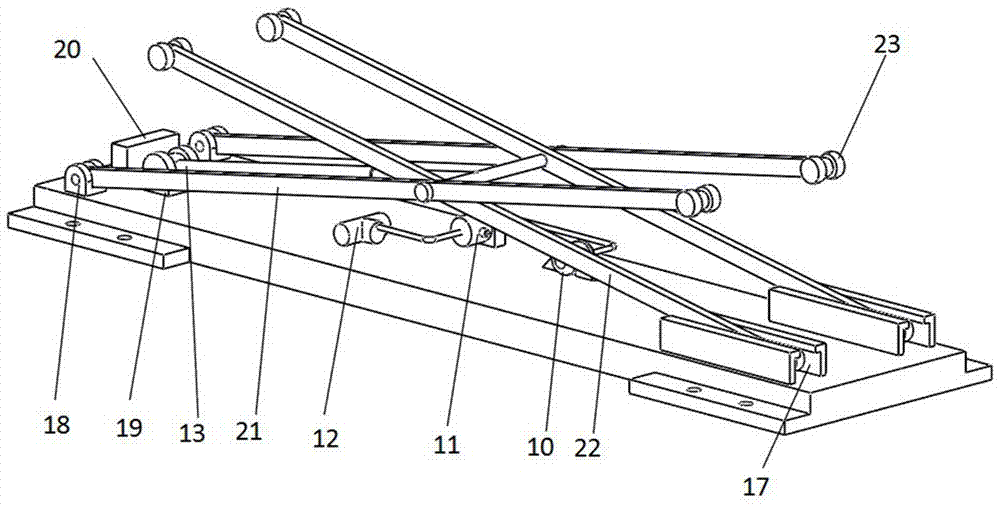

[0031]The hydraulic system includes a pipeline, an electric motor 10, a hydraulic pump 11, a reversing valve 12, a set of fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com