Automatic weighing machine for lithium battery

A lithium battery and weighing machine technology, applied in the field of lithium battery automatic weighing machine devices, can solve the problems of inability to meet consumers' huge demand for lithium batteries, low efficiency, etc., and achieve the effect of improving weighing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

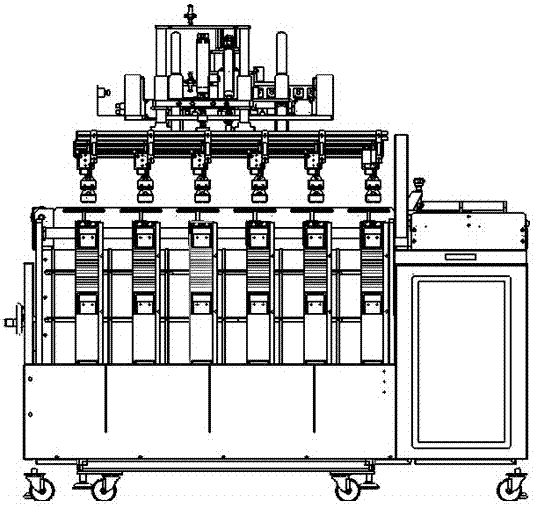

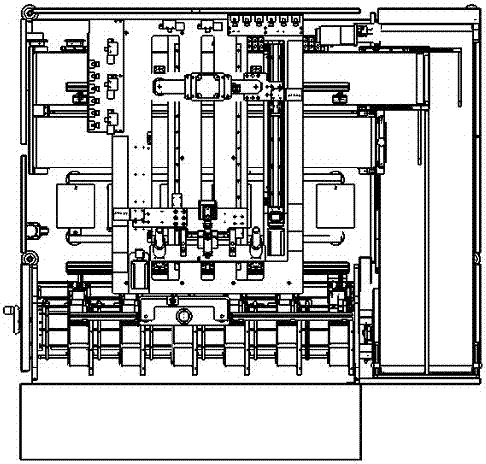

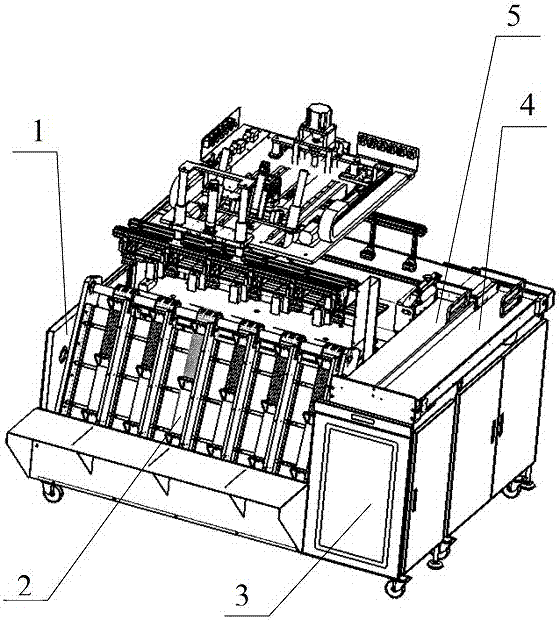

[0042] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0043] A group of lithium batteries is placed on 2, the feeding part, 2, the feeding part is started, and the lithium battery is transported upwards, and when the lithium battery reaches the top of 2, the feeding part, stop running.

[0044] Further, 11. 12. The code scanner of the code scanning component scans the code on the uppermost lithium battery, and transmits the code to the electrical control system in the form of an electrical signal.

[0045] Further, 13. The material-taking moving part takes out the lithium battery after scanning the code, and puts it on 16. The weighing part.

[0046] Further, 16. The weighing component weighs the placed lithium battery.

[0047] Further, 14. The unloading part will take out the weighed lithium battery from 16. The weighing part, and place the lithium battery on the 4. Qualified product output mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com