A fully automatic stacking device for packaging boxes

A technology for stacking equipment and packaging boxes, applied in the directions of transportation and packaging, stacking of objects, conveyors, etc., it can solve the problems of difficulty in ensuring adsorption, deviation, and inability to proceed normally, and achieves the goal of avoiding damage and eliminating displacement deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

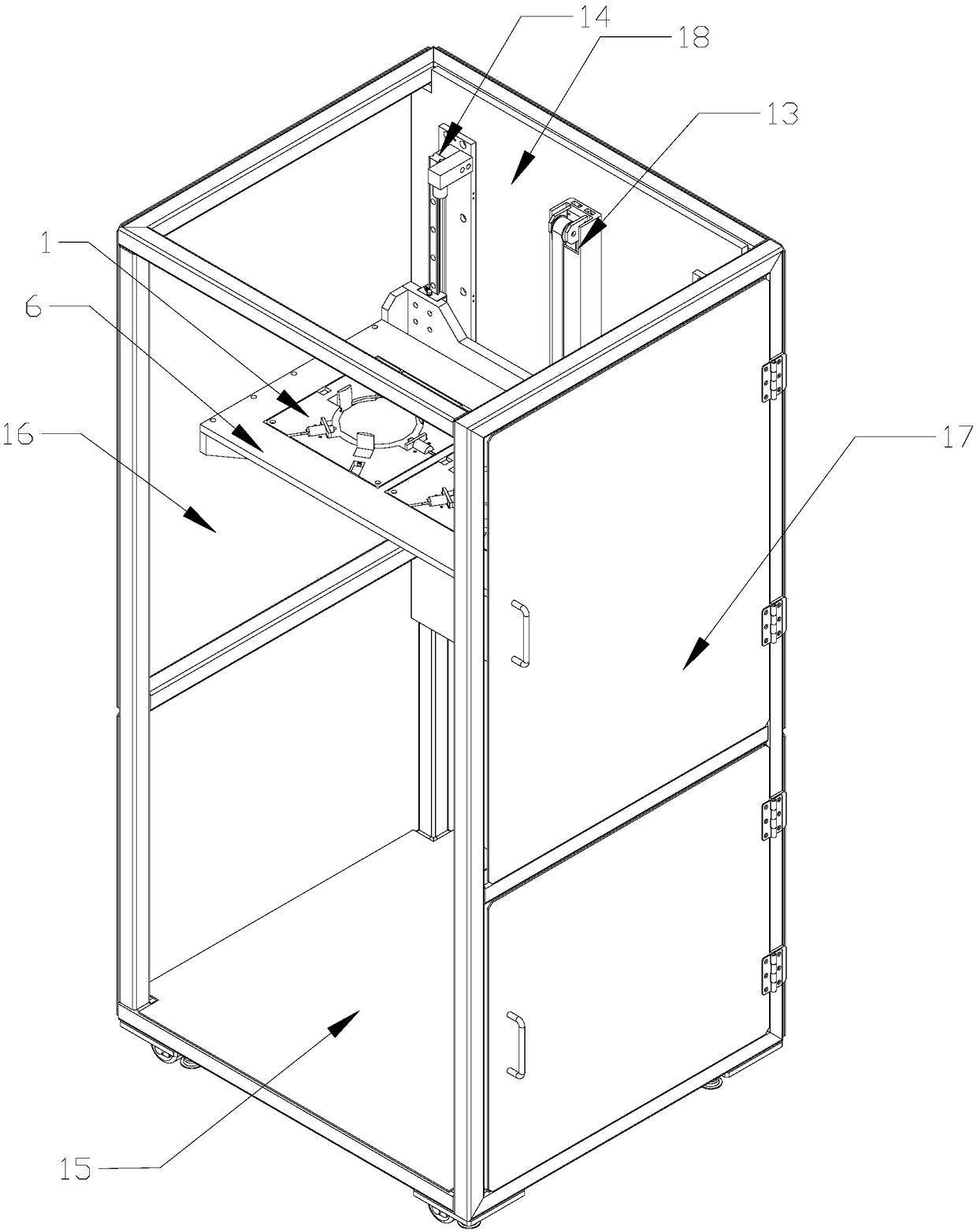

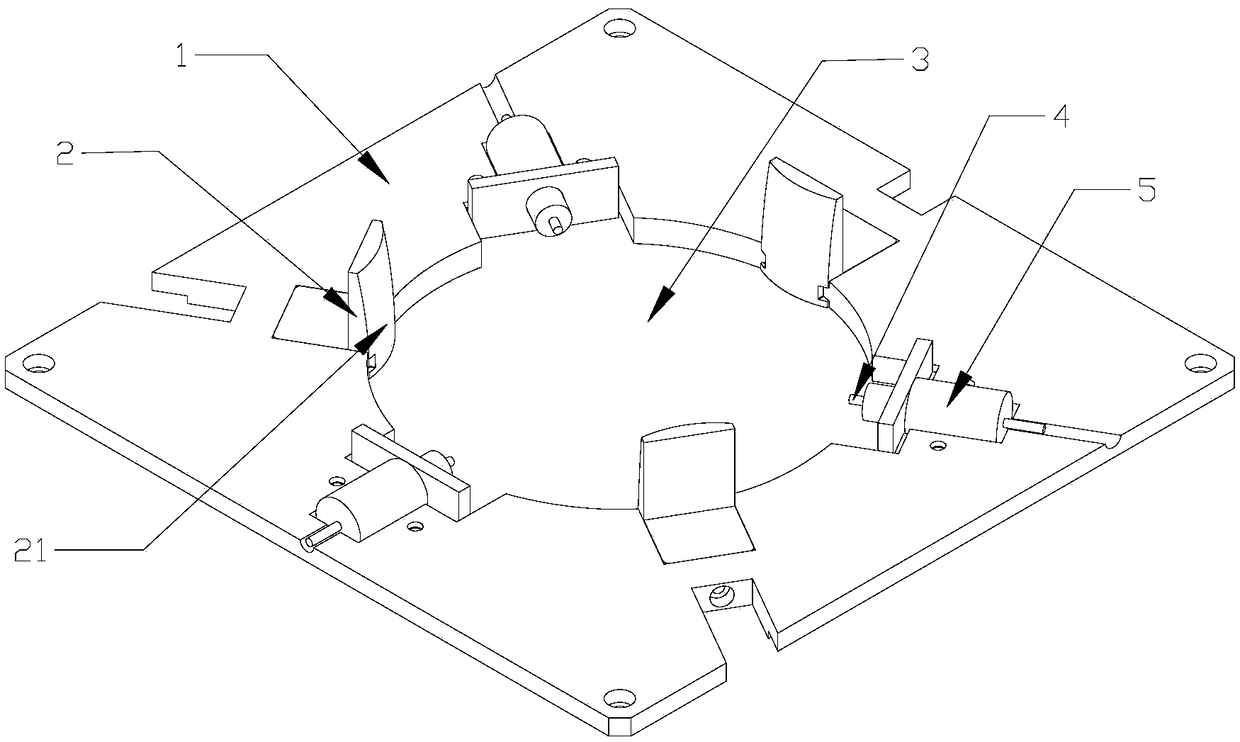

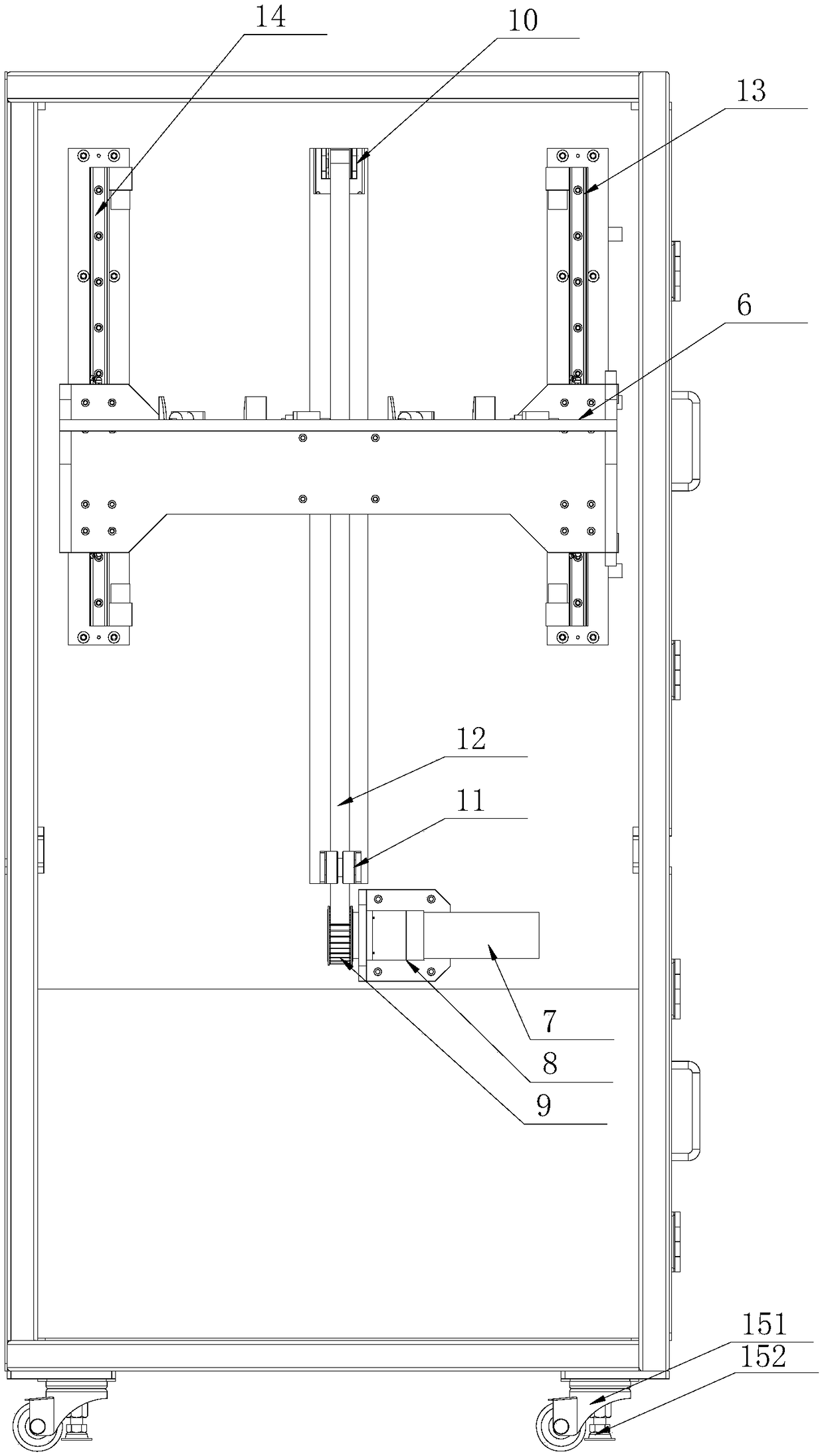

[0017] Embodiment 1: As shown in the figure: a fully automatic stacking equipment for packaging boxes, including a controller, a manipulator, a vacuum suction cup and a pressure sensor for detecting the vacuum degree of the vacuum suction cup, the vacuum suction cup is installed on the manipulator, and the pressure sensor is installed on the vacuum In the suction cup, the controller is respectively connected with the manipulator, the vacuum suction cup and the pressure sensor. The automatic stacking equipment for packaging boxes also includes a limit device. The limit device includes a substrate 1 and n limit blocks 2, where n is an integer greater than or equal to 3. The substrate 1 is provided with a through hole 3, and n number of limit blocks 2 are distributed around the through hole 3. The front end surface 21 of the limit block 2 is an arc surface, and the arc surface is aligned with the center of the through hole 3 from top to bottom. The distance gradually shortens.

...

Embodiment 2

[0019]Embodiment 2: As shown in the figure: a fully automatic stacking device for packaging boxes, including a controller, a manipulator, a vacuum suction cup and a pressure sensor for detecting the vacuum degree of the vacuum suction cup. The vacuum suction cup is installed on the manipulator, and the pressure sensor is installed on the vacuum In the suction cup, the controller is respectively connected with the manipulator, the vacuum suction cup and the pressure sensor. The automatic stacking equipment for packaging boxes also includes a limit device. The limit device includes a substrate 1 and n limit blocks 2, where n is an integer greater than or equal to 3. The substrate 1 is provided with a through hole 3, and n number of limit blocks 2 are distributed around the through hole 3. The front end surface 21 of the limit block 2 is an arc surface, and the arc surface is aligned with the center of the through hole 3 from top to bottom. The distance gradually shortens.

[002...

Embodiment 3

[0022] Embodiment 3: As shown in the figure: a fully automatic stacking device for packaging boxes, including a controller, a manipulator, a vacuum suction cup and a pressure sensor for detecting the vacuum degree of the vacuum suction cup, the vacuum suction cup is installed on the manipulator, and the pressure sensor is installed on the vacuum In the suction cup, the controller is respectively connected with the manipulator, the vacuum suction cup and the pressure sensor. The automatic stacking equipment for packaging boxes also includes a limit device. The limit device includes a substrate 1 and n limit blocks 2, where n is an integer greater than or equal to 3. The substrate 1 is provided with a through hole 3, and n number of limit blocks 2 are distributed around the through hole 3. The front end surface 21 of the limit block 2 is an arc surface, and the arc surface is aligned with the center of the through hole 3 from top to bottom. The distance gradually shortens.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com