Torch combustor adapting to high load, multiple work conditions and high-low heat value

A technology of torch combustion and multi-working conditions, which is applied in the field of processing high calorific value and low calorific value flare gas at the same time, can solve the problems that it is difficult to meet the change of load and calorific value at the same time, and the function is single, so as to achieve good economic benefits and ensure operation Safety, convenient maintenance and overhaul, and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

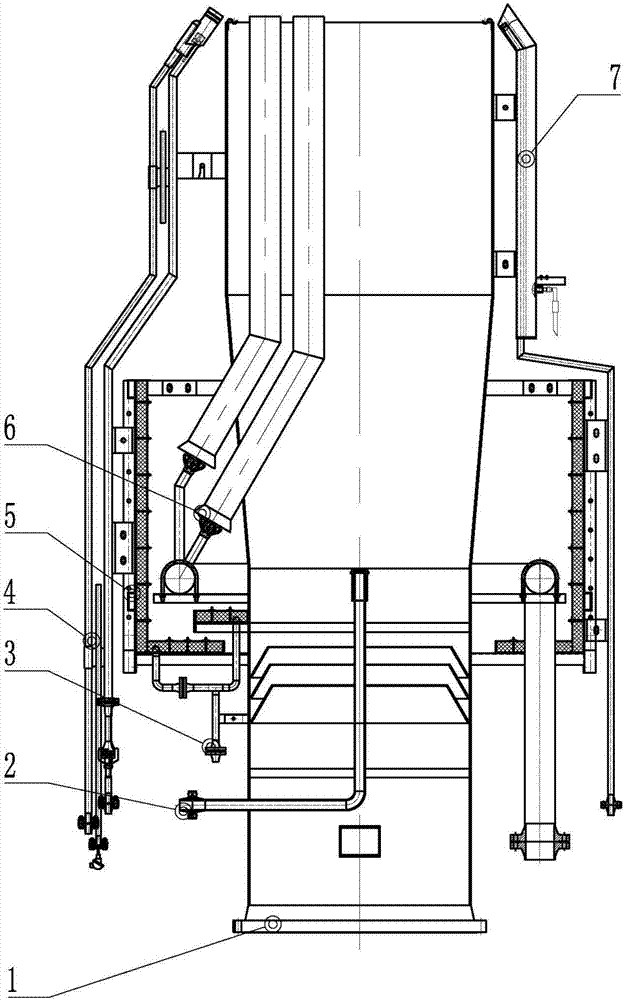

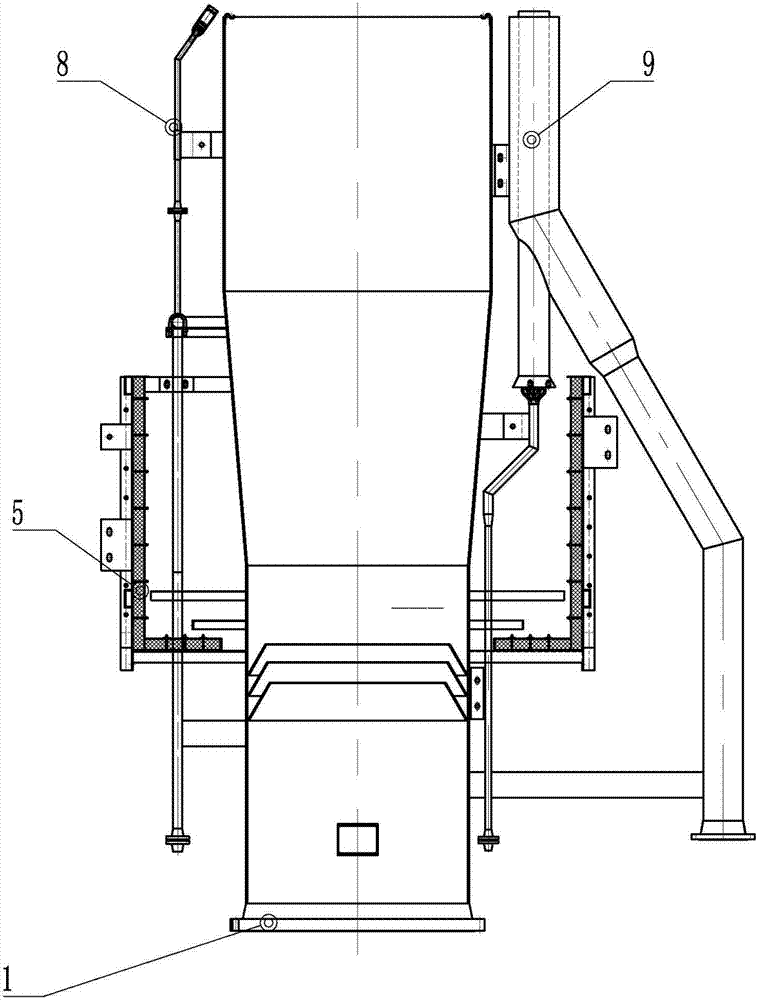

[0015] like figure 1 , figure 2 As shown, the torch burner adapted to large load, multiple working conditions, and high and low calorific value in the present invention includes a cylinder body 1, a bottom purge steam pipe 2, a heat tracing pipe 3, an ever-burning lamp 4, a sound-absorbing cover 5, and a center injection steam Tube 6, high-altitude igniter 7, burner 8, small flow cylinder 9;

[0016] The small flow cylinder 9 is connected side by side with the cylinder 1 in parallel, and the long light 4 and the high-altitude igniter 7 are connected to the position of the cylinder 1 close to the small flow cylinder 9 through high temperature resistant stainless steel bolts, and the small flow cylinder 9 is shared with the cylinder 1 Eternal light 4 and high-altitude igniter 7; cylinder body 1 is provided with a bottom purge steam pipe 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com