Measuring cylinder and measuring glass overlook device

A technology for measuring cups and measuring cylinders, which is applied in the field of measuring cylinders and measuring cups, and can solve the problems of inconvenient side-view readings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

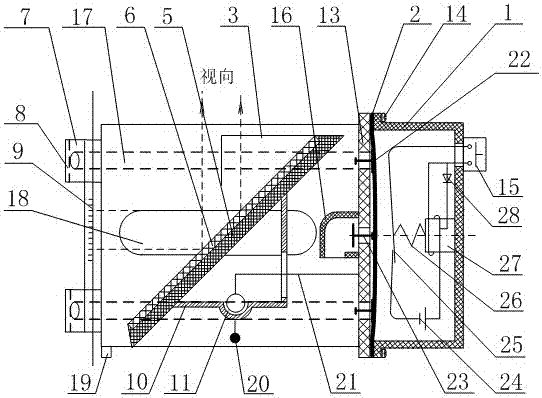

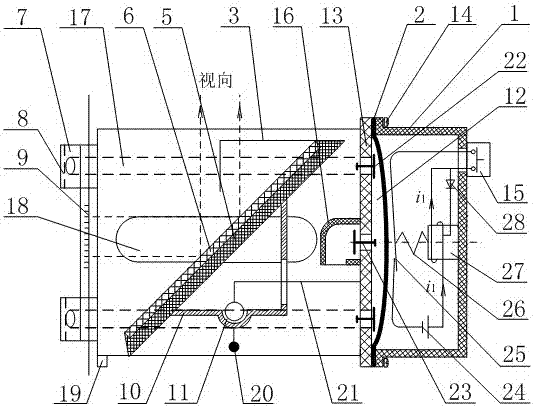

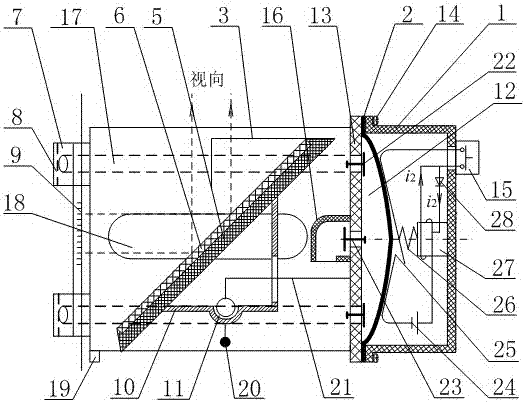

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] like figure 1 , as shown in 2, a measuring cylinder and measuring cup downward reading device, including a cover 1, a rubber magnetic film 2, an L-shaped overhanging vertical needle 3, a right groove wall 4-1, a left groove wall 4-2, a mirror frame 5, an embedded Mirror surface 6, hollow rubber suction cup 7, bracket grid 10, joint bearing 11, groove base 13, screw 14, normally open button 15, exhaust pipe air guide cover 16, air intake pipe 17, light transmission hole 18, foot 19, Metal gravity ball 20, cantilever 21, intake check valve 22, exhaust check valve 23, button battery 24, metal reed 25, spring 26, iron core coil 27, diode 28.

[0025] The rubber magnetic film 2 is composed of elastic soft magnetic rubber magnets. The rubber magnetic film 2 is sandwiched between the case 1 and the groove base 13. The three are connected and fixed with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap