Standard torque wrench calibration device based on deadweight torque standard machine and method thereof

A technology of verification device and standard machine, which is applied in the direction of measuring torque/torsion force, measuring device, calibration/testing of force/torque/power measuring instrument during tightening, and can solve the problems of difficulty in guaranteeing the accuracy of the calibration device, low detection efficiency, Does not consider the influence of torque indication and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

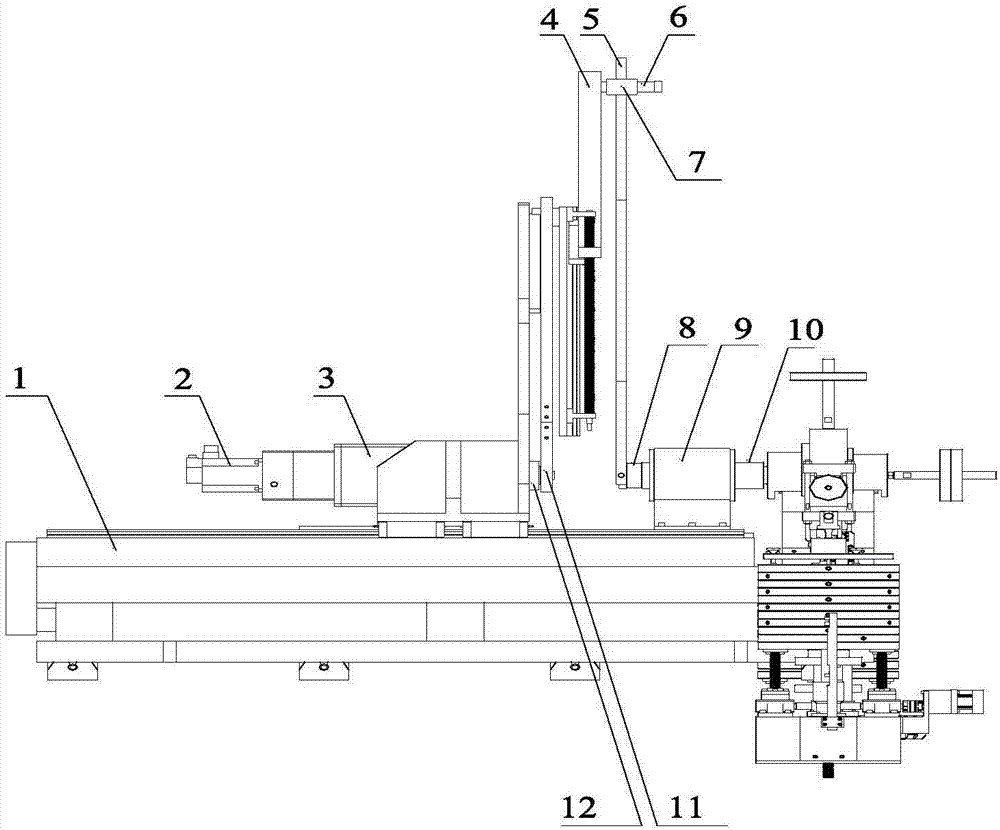

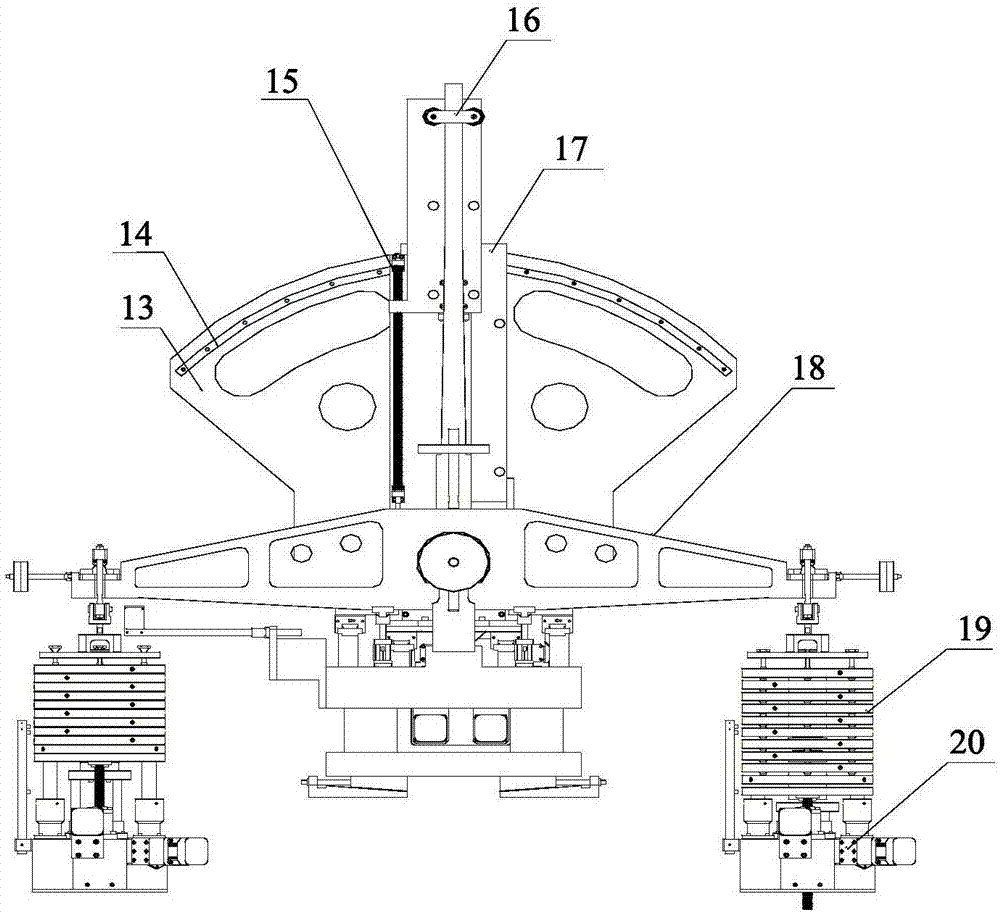

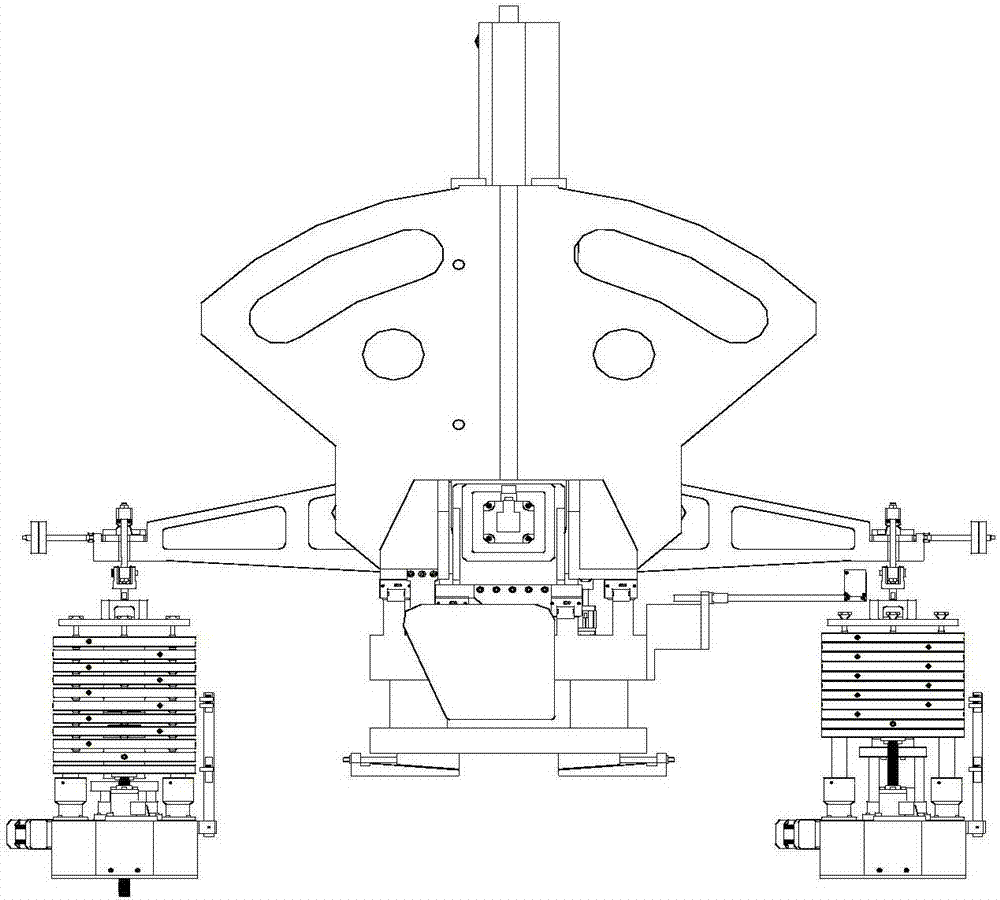

[0028] The present invention provides a standard torque wrench verification device based on a deadweight torque standard machine, comprising: a deadweight torque standard machine, an outer guide rail 22, a verification unit and a hydrostatic bearing 9; the deadweight torque standard machine It includes a body 1, a servo motor 2, a reduction mechanism 3, an equal arm lever 18, a force weight 19, a weight loading and unloading mechanism 20, and an inner guide rail 21. The inner guide rail 21 is arranged on one side of the body 1, and the inner guide rail 21 Servomotor 2 and deceleration mechanism 3 are arranged in turn above guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com