Sand-discharging type ventilated sweat-wicking shoes

A sand type, heel technology, applied in footwear, soles, clothing and other directions, can solve the problems of unsuitable leather shoes, uncivilized, affecting comfort, etc., to achieve low production costs, increase the applicable environment, and improve the effect of comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

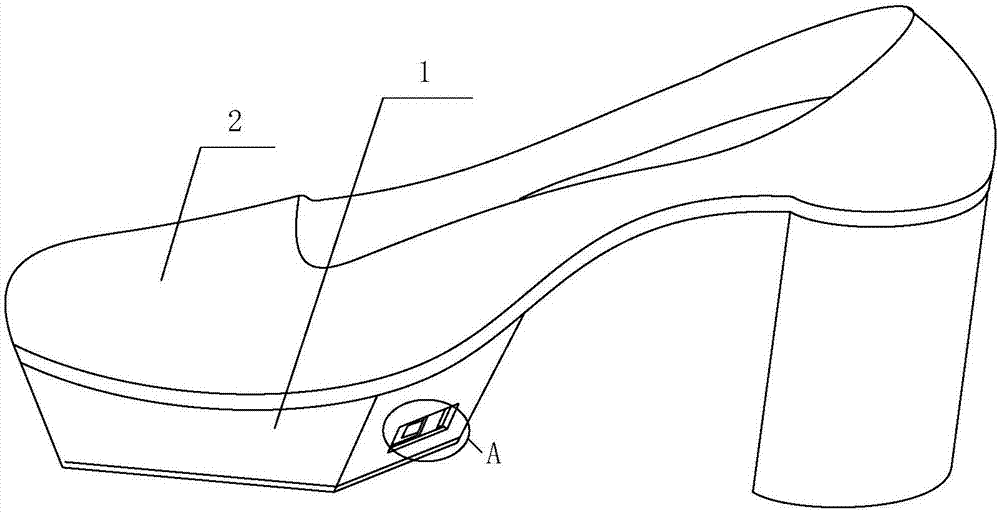

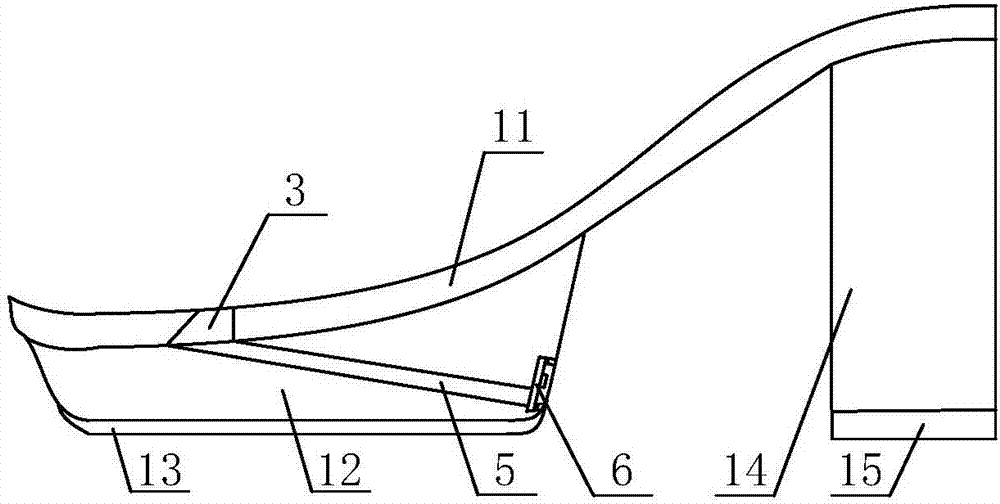

[0027] A sand-discharging ventilating and sweat-wicking shoe, such as Figure 1-Figure 3 As shown, the sole 1 comprising a high sole, and the vamp 2 arranged on the sole 1; the sole 1 comprises a midsole 11, a waterproof platform 12 arranged at the position in front of the midsole 11, and a waterproof platform 12 arranged at the bottom of the waterproof platform 12 Outsole 13, the heel 14 arranged at the rear position of the midsole 11, the sky skin 15 arranged at the bottom of the heel 14; it is characterized in that,

[0028] The front of the midsole 11 is provided with a through hole 3 at the joint between the toe and the sole of the foot, and the side wall of the waterproof platform 12 is provided with an opening 4. The waterproof platform 12 below the through hole 3 is provided with an end communicating with the through hole 3. The other end communicates with the channel 5 of the opening 4 .

[0029] The opening 4 is disposed on the side wall of the waterproof platform 1...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the structures of the opening 4, the through hole 3 and the channel 5 are optimized, and the specific settings are as follows:

[0032] The shape of the through hole 3 is rectangular, the long side of the through hole 3 is 1 / 2-2 / 3 of the width of the midsole 11 at the position of the through hole 3, and the short side of the through hole 3 is 1-3mm.

[0033] The height of the opening 4 is the same as the width of the through hole 3 , and the length of the opening 4 is 1 / 3˜1 / 2 of the length of the through hole 3 .

[0034] The shape of the channel 5 is funnel-like.

Embodiment 3

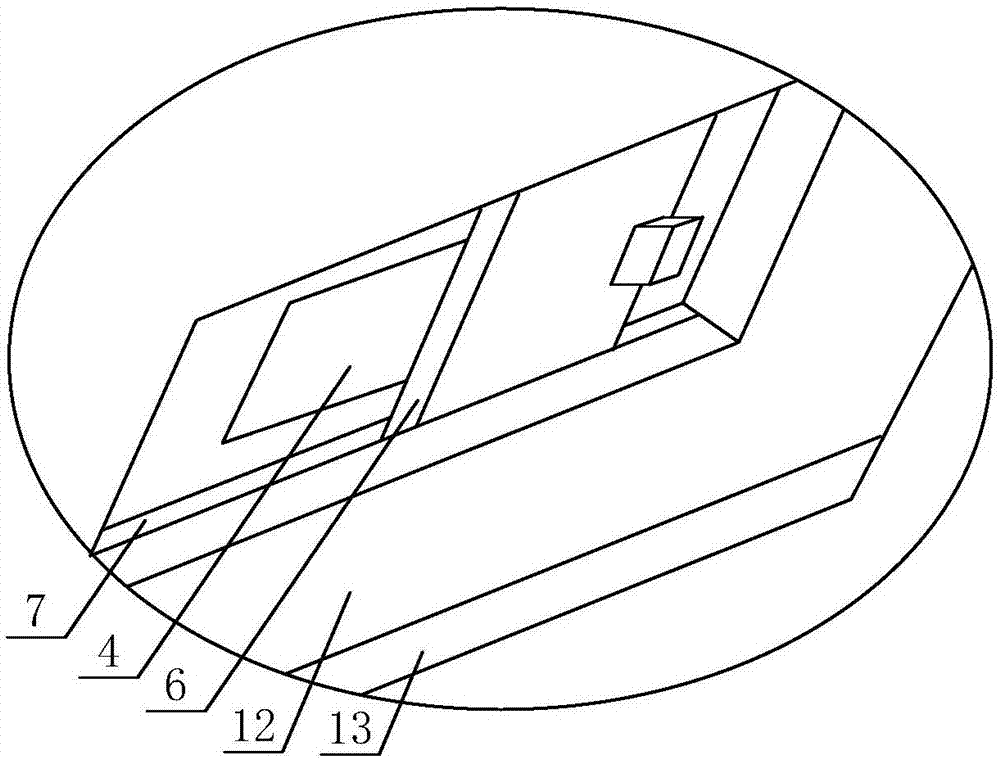

[0036] The difference between this embodiment and Embodiment 1 is that this embodiment increases the structure of the shroud 6 and the chute 7, and the specific settings are as follows:

[0037] A shroud 6 is also provided at the opening 4 , and the shroud 6 is slidably connected to the waterproof platform 12 through the slide groove 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com