Gantry type scissor-fork grabbing manipulator

A grabbing manipulator and gantry-type technology, applied in the field of gantry manipulators, can solve the problems of difficulty in meeting the requirements of high-efficiency and large-scale outbound, inconvenient digital management, slow reflection speed of inbound and outbound, etc., to achieve efficient and stable three-axis linear compound motion, The effect of shortening the preparation time for the action and making the action quicker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

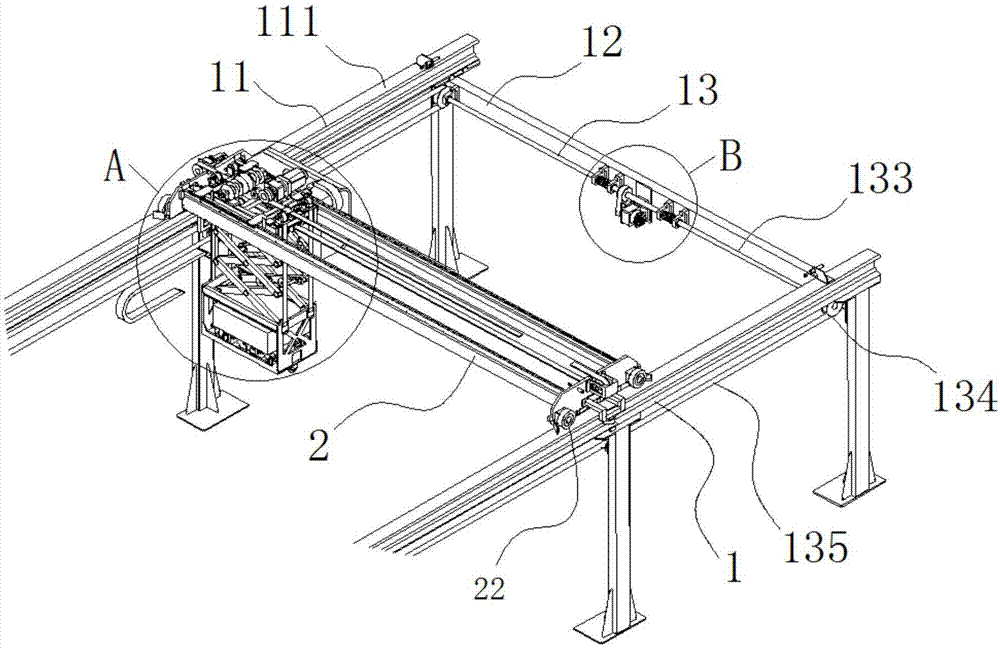

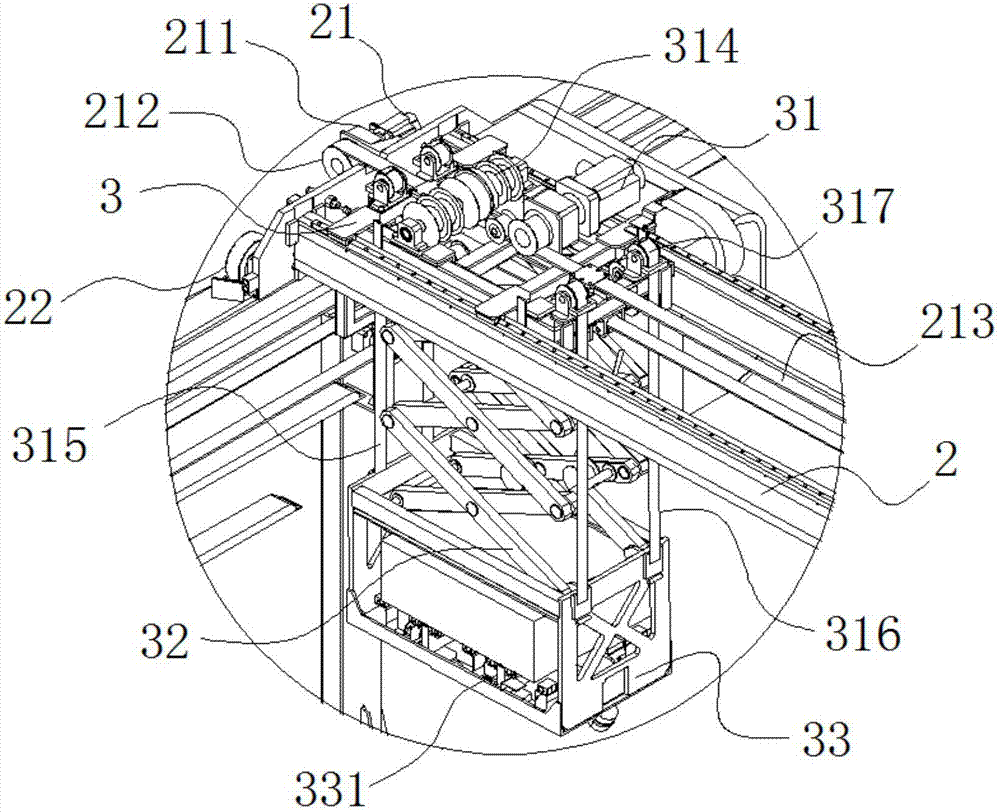

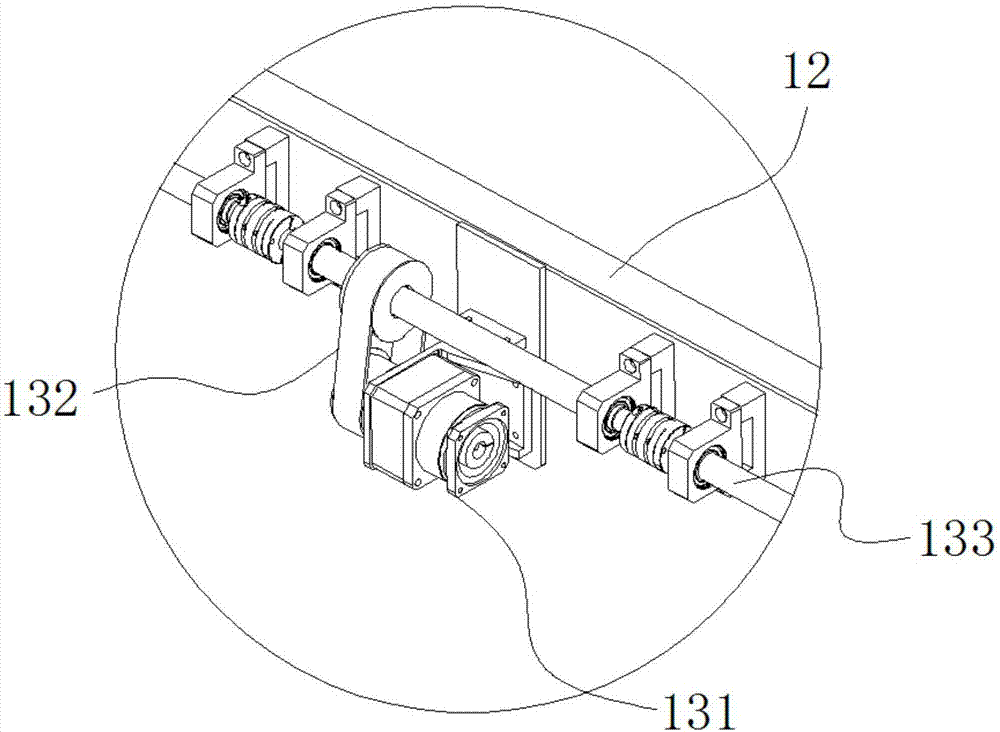

[0019] Figure 1~5 As shown, the gantry type scissor grabbing manipulator includes a gantry vertical frame 1, a movable cross beam 2 and a movable sliding seat 3. The gantry vertical frame 1 is a two-sided vertical frame structure with a top beam 11 on the upper part. The movable beam 2 is mounted on the top beam body 11, the rear end of the gantry vertical frame 1 is provided with a fixed beam frame 12, and an X-axis belt drive mechanism 13 connected to both ends of the movable beam 2 is installed on the fixed beam frame 12 The moving beam 2 realizes linear movement in the X-axis direction on the top beam body 11 through the X-axis belt drive mechanism 13; the moving beam 2 is equipped with a Y-axis belt drive mechanism 21, and the moving slide 3 passes through a straight line The slide rail device is installed on the moving beam 2. The moving slide 3 realizes the linear movement in the Y axis direction on the moving beam 2 through the Y-axis belt drive mechanism 21; the upper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap