Workpiece picking robot

A technology of robots and reducers, applied in the field of robots, can solve problems such as cumbersome processing, and achieve the effect of reducing labor intensity and improving the efficiency of workpiece transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

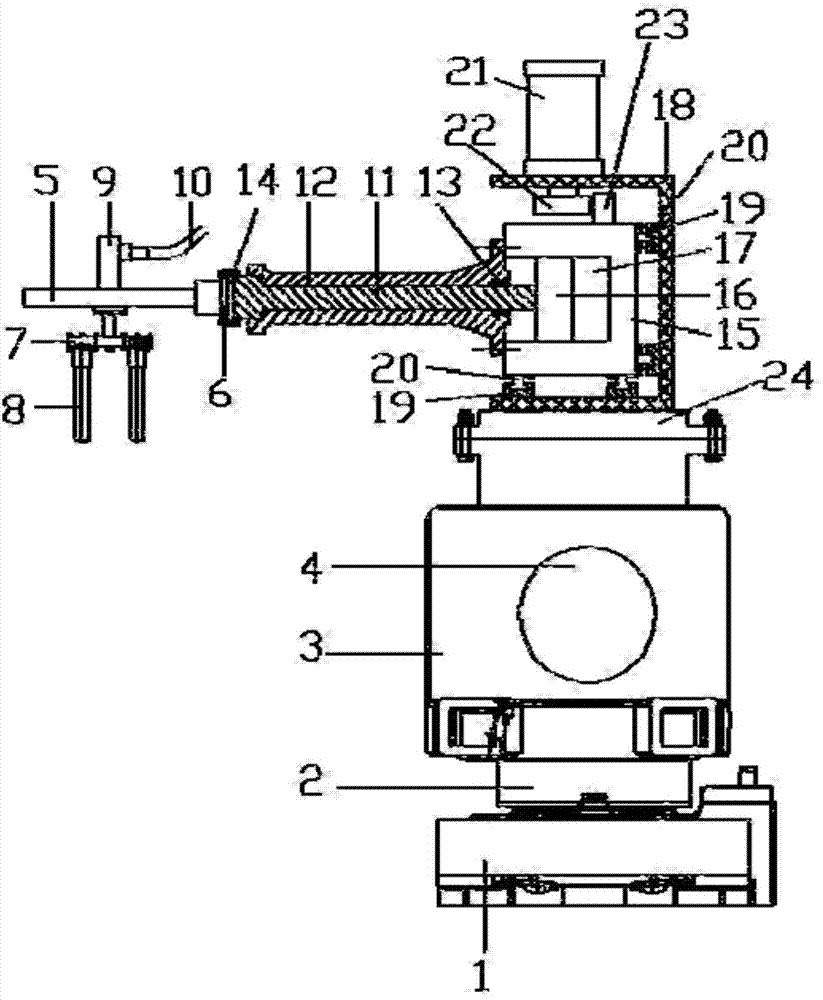

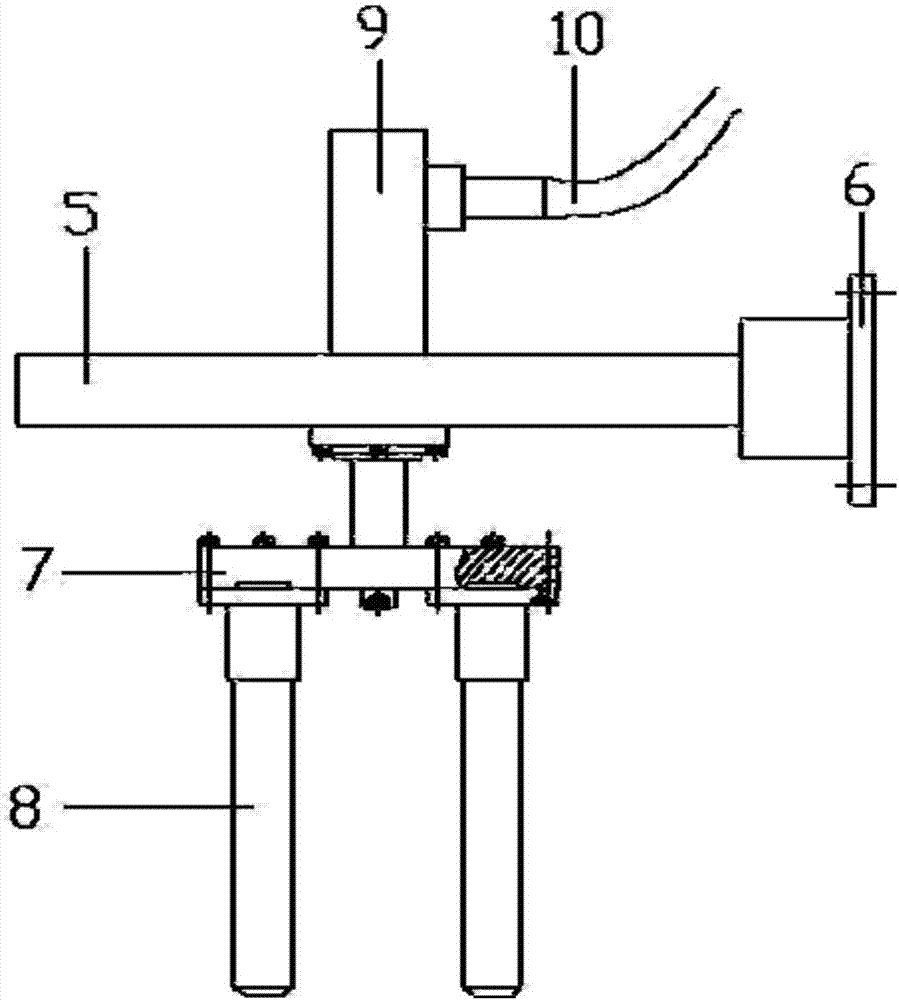

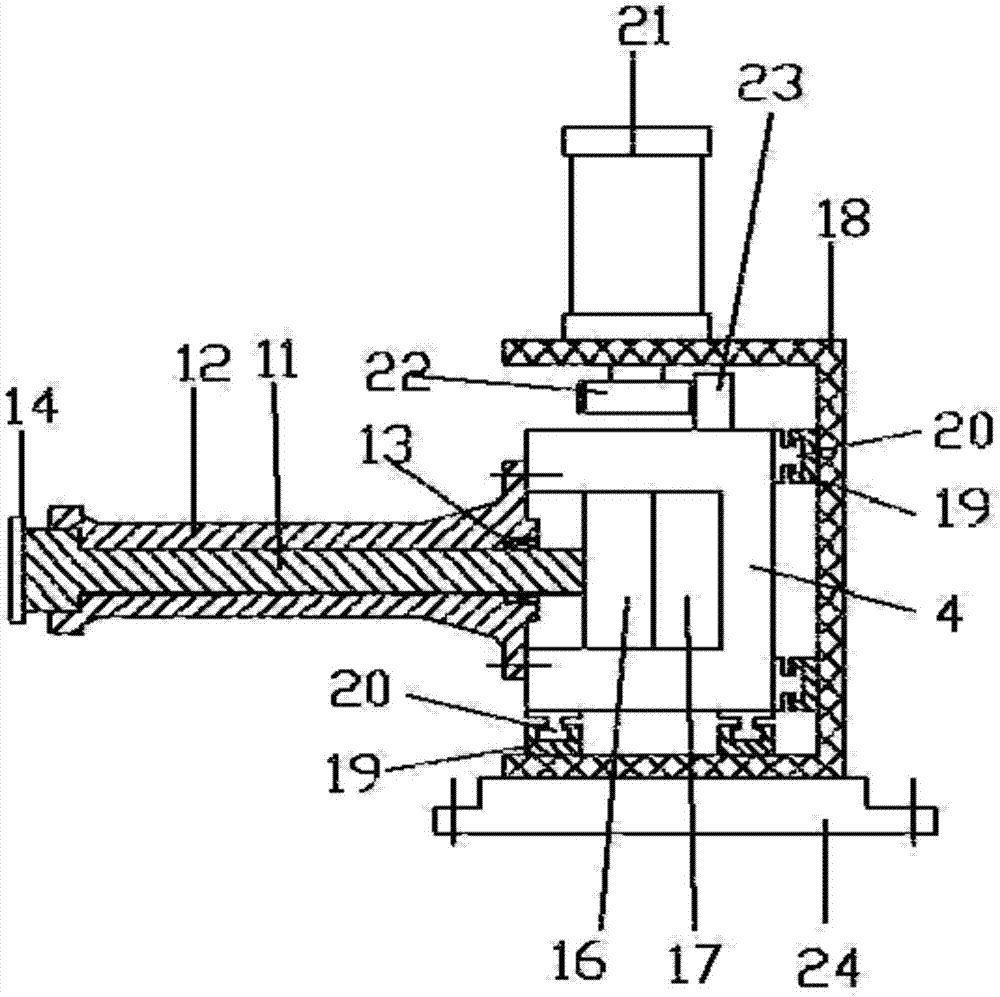

[0016] Example: see Figures 1 to 3 As shown, the pick-up robot includes a base 1, a drum 3, a robot reducer 2 and a drum motor 4, the drum motor 4 is fixed on the drum 3, the robot reducer 2 is fixed on the drum 3, and the drum motor The rotating shaft of 4 is fixed with the input shaft of the robot reducer 2, and the output shaft of the robot reducer 2 is fixed on the base 1. It is characterized in that: the suction cup flange 6 is fixed on the suction cup frame 5, and the bottom of the suction cup 7 is fixed with The suction nozzle 8, the ventilation pipe 9 are connected with the suction cup 7, the ventilation pipe 9 is fixed on the suction cup frame 5, and the ventilation pipe 9 is connected with the air pressure station through the hose 10;

[0017] The main shaft 11 is inserted into the housing 12, the inner ring of the bearing 13 is fixed with the main shaft 11, the outer ring of the bearing 13 is fixed on the inner wall of the housing 12; the main shaft flange 14 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com