Bonding device and bonding method

A laminating device and a laminating jig technology, which are applied in household appliances, other household appliances, household components, etc., can solve problems affecting product quality, low yield rate, and inability to fully discharge air bubbles, etc., to achieve good lamination effect, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

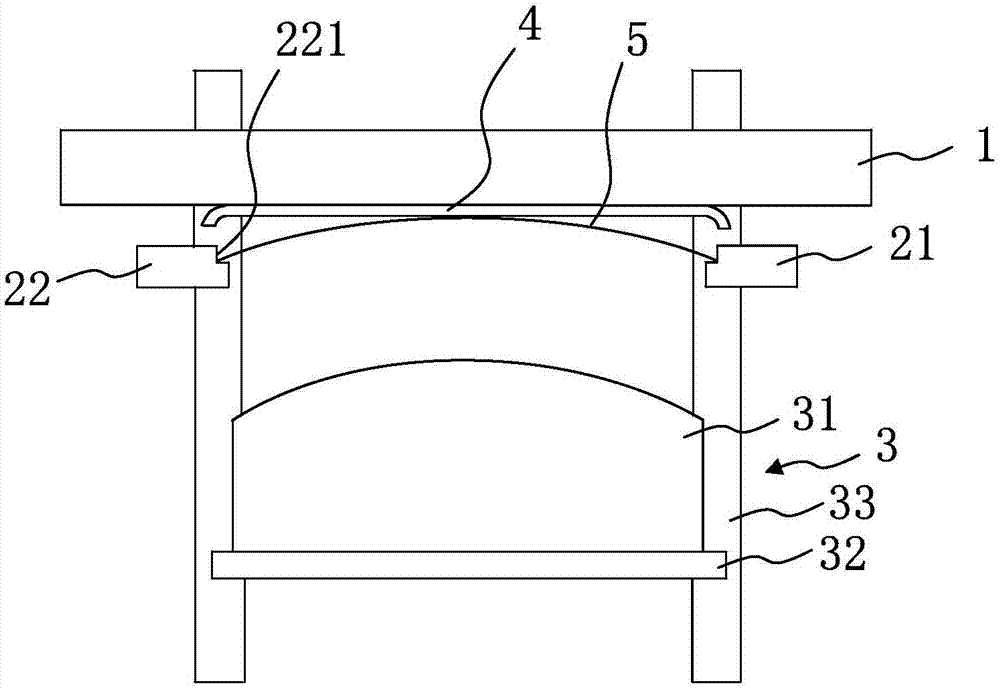

[0030] figure 1 It is a schematic structural diagram of the bonding device in the first embodiment of the present invention. Such as figure 1 As shown, the laminating device of this embodiment includes a cover plate positioning mechanism 1 , a flexible screen body positioning mechanism and a laminating jig 3 .

[0031] The cover plate positioning mechanism 1 is used for fixing the cover plate 4 . Specifically, the cover positioning mechanism 1 can fix the cover 4 by means of vacuum adsorption, so that the cover 4 can be positioned toward the flexible screen body positioning mechanism. In this embodiment, the edge regions of the long sides on both sides of the cover plate 4 are curved surfaces, that is, the long sides on both sides of the cover plate 4 are provided with R angles. It can be understood that, according to the shape design of the cover plate 4 , the edge regions of the short sides on both sides of the cover plate 4 may also be curved surfaces, that is, the short...

no. 2 example

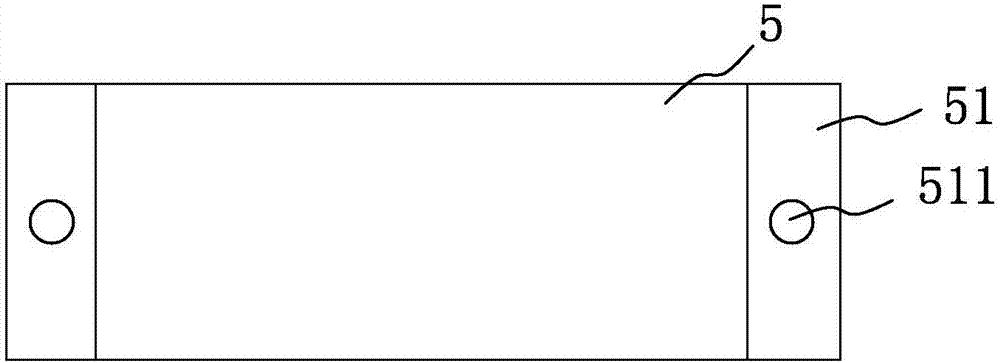

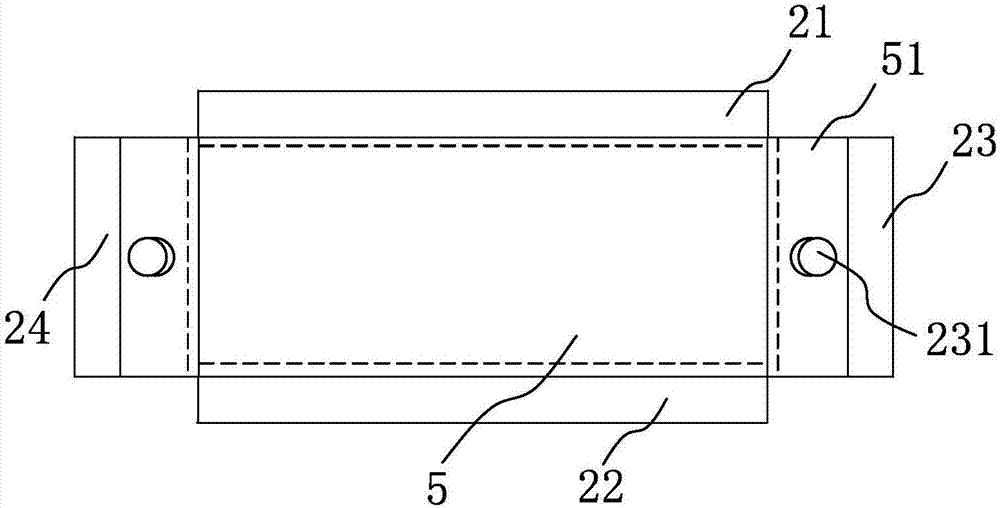

[0039] figure 2 It is a schematic structural diagram of the flexible screen body in the second embodiment of the present invention. image 3 It is a schematic diagram of the positioning method of the flexible screen in the second embodiment of the present invention. Figure 4 It is a schematic structural diagram of the bonding device in the second embodiment of the present invention. In addition, for the structural diagram of the laminating device in this embodiment in another direction, please refer to figure 1 . Such as Figure 1 to Figure 4 As shown, the main difference between the laminating device of this embodiment and the first embodiment is that the flexible screen body positioning mechanism also includes a third positioning seat 23 located between the first positioning seat 21 and the second positioning seat 22 and opposite to each other. with the fourth positioning seat 24, wherein, image 3 It is only for illustration, and is not used to define the distance re...

no. 3 example

[0046] Figure 5 It is a schematic flow chart of the bonding method in the third embodiment of the present invention. Such as Figure 5 Shown, bonding method of the present invention may comprise the following steps:

[0047]Step 61, fixing the cover plate on the cover plate positioning mechanism.

[0048] Specifically, the cover positioning mechanism 1 can fix the cover 4 by means of vacuum adsorption, so that the cover 4 can be positioned toward the flexible screen body positioning mechanism. In this embodiment, the edge regions of the long sides on both sides of the cover plate 4 are curved surfaces, that is, the long sides on both sides of the cover plate 4 are provided with R angles. It can be understood that, according to the shape design of the cover plate 4 , the edge regions of the short sides on both sides of the cover plate 4 may also be curved surfaces, that is, the short sides on both sides of the cover plate 4 are provided with R angles. Certainly, the cover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com